Impeller crushing machine

A pulverizer and impeller technology, applied in grain processing and other directions, can solve the problems of inability to work continuously, difficult maintenance, easy heating of the machine, etc., and achieve the effect of improving pulverization efficiency, high pulverization efficiency and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

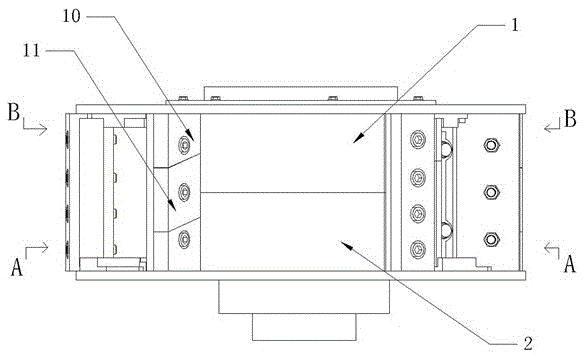

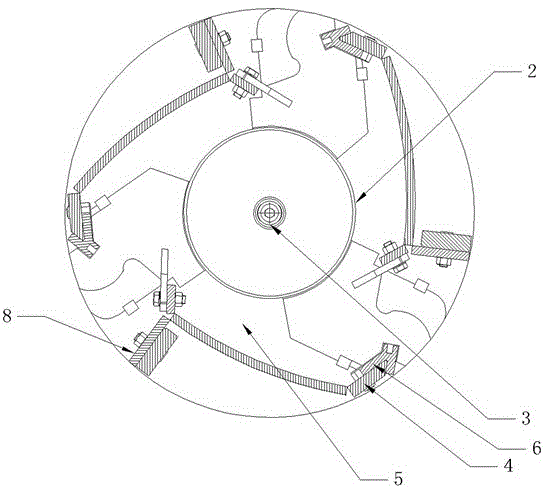

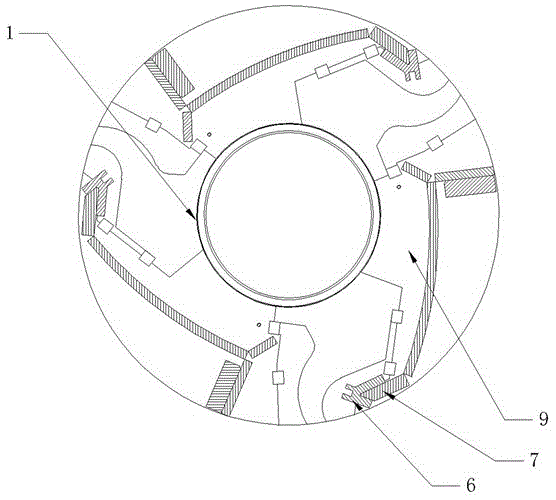

[0021] Such as Figure 1-Figure 3 The shown impeller pulverizer includes an impeller assembly and a main shaft; the impeller assembly includes an upper impeller and a lower impeller, and the main shaft includes a primary main shaft 1 and a secondary main shaft 2; the upper impeller and the primary main shaft 1 are connected through an expansion sleeve, and the lower impeller It is connected with the secondary main shaft 2 through an expansion sleeve, and the rotation directions of the primary main shaft 1 and the secondary main shaft 2 are opposite; the lower end of the secondary main shaft 2 is provided with a material distribution cone 3, which is in the shape of a trapezoidal cylinder; There are 3 crushing blades evenly arranged, and the crushing blades include the lower throwing head 4, the wear-resistant baffle 8 and the lower connecting arm 5; one end of the lower connecting arm 5 is connected to the primary spindle 1, and the other end is connected to the lower throwing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com