Ship cross section assignment method

A cross-section and ship technology, applied in ship components, ship construction, ship design, etc., can solve the problems of difficult adjustment of ship bottom level, low dock utilization rate, and low planning accuracy, so as to improve dock utilization rate and reduce costs , the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

[0027] Note that the terms "height" and "distance" used in this article refer to the vertical length from point to surface or from surface to surface.

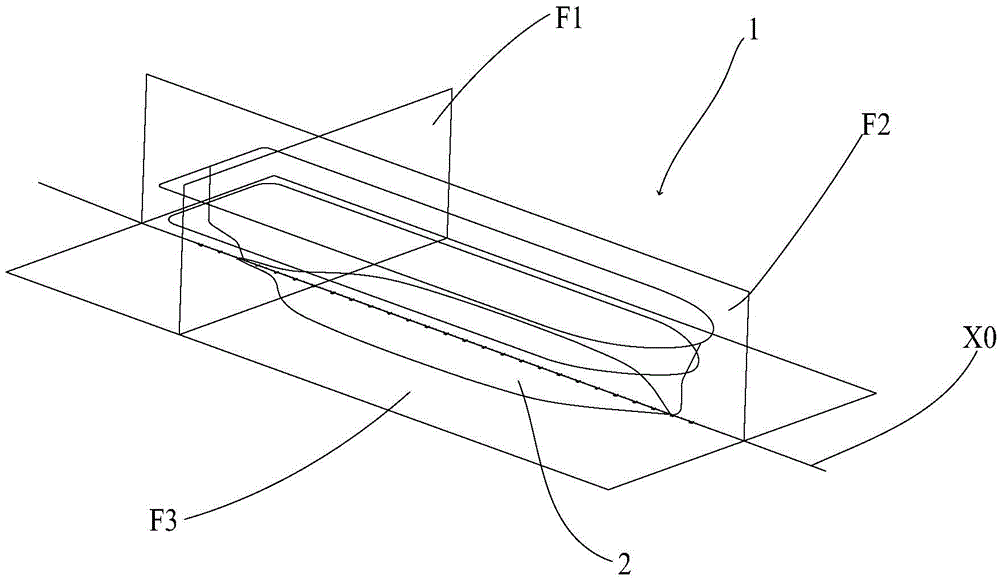

[0028] figure 1 It is a schematic diagram of a ship 1 according to an embodiment of the present invention. figure 1 The rough shape of the ship 1 is depicted only according to needs. Below, will be based on figure 1 The method for mapping the ship cross-section F1 according to the embodiment of the present invention will be described in detail. The mapping method includes the following steps:

[0029] S1: In the cabin of the ship 1, on the inner bottom plate 2 of the ship 1, near the front bulkhead or the rear bulkhead, a laser theodolite (usually J2 laser theodolite produced by Suzhou Yiguang Instrument Co., Ltd.) is installed, and the laser The theodolite will emit a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com