A kind of conductive graphene and preparation method thereof

A technology of graphene and conductivity, which is applied in the field of conductive graphene and its preparation, can solve the problems of reduced conductivity, tedious time-consuming, difficult to meet, etc., to achieve the reduction of oxygen-containing functional group residues, fast and simple preparation method, high conductivity excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

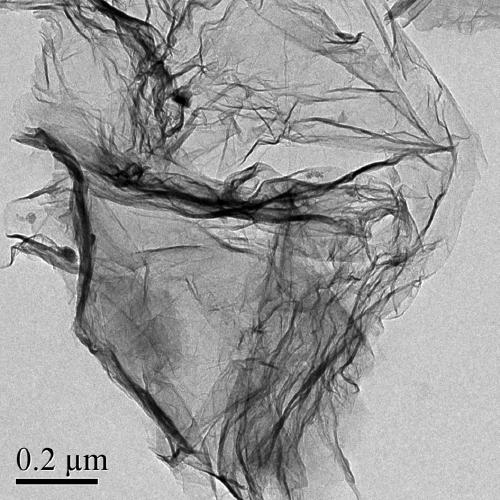

Image

Examples

Embodiment 1

[0028] A kind of conductive graphene, its preparation process is as follows:

[0029] S1. Mix 20g of concentrated sulfuric acid and 5g of hydrogen peroxide with 2g of graphite, heat to 60°C for 5 hours, and then ultrasonically react for 30 minutes;

[0030] S2, adding 100ml of sodium borohydride with a concentration of 1mol / L and 40ml of sodium hydroxide with a concentration of 1mol / L to react for 4 hours, control the centrifuge speed at 15000 rpm, centrifuge for 10min, and wash with absolute ethanol 3 times. Then dry at 80°C to obtain graphene.

Embodiment 2

[0032] A kind of conductive graphene, its preparation process is as follows:

[0033] S1. Mix 10g of concentrated nitric acid with a mass concentration of 98% and 5g of hydrogen peroxide with 1g of graphite, heat to 80°C for 5 hours, and then ultrasonically react for 50 minutes;

[0034] S2, adding 60ml of sodium borohydride with a concentration of 1mol / L and 20ml of sodium hydroxide with a concentration of 1mol / L to react for 2 hours, control the centrifuge speed to 15000 rpm, centrifuge for 10min, and wash 3 times with absolute ethanol. Then dry at 100°C to obtain graphene.

Embodiment 3

[0036] A kind of conductive graphene, its preparation method process is as follows:

[0037] S1. Mix 10g of concentrated sulfuric acid and 2g of hydrogen peroxide with 2g of graphite, heat to 80°C for 3 hours, and then ultrasonically react for 50min;

[0038] S2, adding 70ml of potassium borohydride with a concentration of 1mol / L and 40ml of potassium hydroxide with a concentration of 1mol / L to react for 3 hours, control the centrifuge speed to 10000 rpm, centrifuge for 15min, wash 4 times with absolute ethanol, Then dry at 80°C to obtain graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com