High-conductivity nano mineral modified full-degradable polymer composite material and preparation method thereof

A nano-mineral modification and composite material technology, which is applied in the field of high-conductivity nano-mineral modified fully degradable polymer composite materials and its preparation, can solve problems such as hindering fiber performance, filler agglomeration, and fiber material processing difficulties, and achieve good processing Realization of sex and function, improvement of interface binding force, and good enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

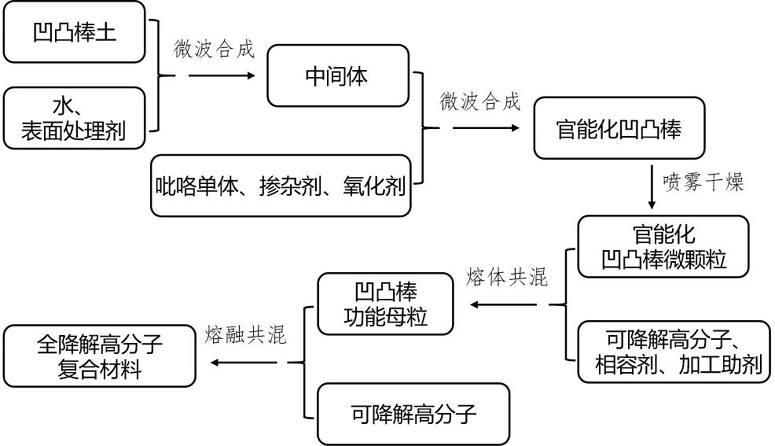

[0027] Such as figure 1 As shown, the preparation method of a kind of highly conductive nano-mineral modified fully degradable polymer composite material provided by the present invention comprises the following steps:

[0028] S11. Preparation of intermediates: add 25 parts by mass of attapulgite and 10.7 parts by mass of cetyltrimethylammonium bromide to 75 parts by mass of water, mix well, put them into a microwave reactor, and heat up under stirring to 50°C, finish the reaction after 5 minutes, and cool to obtain an aqueous dispersion containing the intermediate;

[0029] S12. Preparation of functionalized attapulgite: In the state of stirring, continue to add pyrrole monomer, sodium benzenesulfonate and sodium persulfate in sequence to the microwave reactor, wherein the pyrrole monomer is 12.5 parts by mass, sodium benzenesulfonate and pyrrole The molar ratio of monomers is 1:1.4, the molar ratio of sodium persulfate to pyrrole monomer is 1:2, and the oxidative polymeriz...

Embodiment 2

[0034] A highly conductive nano-mineral modified fully degradable polymer composite material and a preparation method thereof, comprising the following steps:

[0035] S21. Preparation of intermediate: add 1 mass part of attapulgite and 0.011 mass part of aminosilane coupling agent to 99 mass parts of water, mix well, put it into a microwave reactor, and raise the temperature to 120 °C under stirring, and react End and cool after 30 seconds to obtain an aqueous dispersion containing the intermediate;

[0036] S22. Preparation of functionalized attapulgite: in the state of stirring, continue to add pyrrole monomer, sodium dodecylsulfonate and potassium persulfate in sequence to the microwave reactor, wherein, pyrrole monomer is 0.2 parts by mass, dodecane The molar ratio of sodium sulfonate to pyrrole monomer is 1:7, the molar ratio of potassium persulfate to pyrrole monomer is 1:0.6, and the oxidative polymerization reaction is carried out at 25 ° C for 30 minutes to obtain an...

Embodiment 3

[0041] The present invention provides a highly conductive nano-mineral modified fully degradable polymer composite material and a preparation method thereof, comprising the following steps:

[0042] S31. Preparation of intermediates: add 10 parts by mass of attapulgite and 1 part by mass of cetyltrimethylammonium bromide to 90 parts by mass of water, mix well, put them into a microwave reactor, and heat up while stirring to 80°C, the reaction was completed after 2 minutes, and cooled to obtain an aqueous dispersion containing the intermediate;

[0043] S32. Preparation of functionalized attapulgite: in the state of stirring, continue to add pyrrole monomer, polyethylene glycol p-isooctylphenyl ether and ammonium persulfate sequentially into the microwave reactor, wherein the pyrrole monomer is 2.5 parts by mass , the molar ratio of polyethylene glycol to isooctylphenyl ether and pyrrole monomer is 1:5, the molar ratio of ammonium persulfate to pyrrole monomer is 1:1, and the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com