Furnace door type thermal insulation composite covering method and device for aluminum electrolytic cell

A technology of aluminum electrolytic cell and covering device, which is applied in the field of aluminum electrolysis, and can solve problems such as difficulty in standardization of electrolytic cell display characteristics, adjustment of thermal conditions, difficulty in monitoring and implementation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

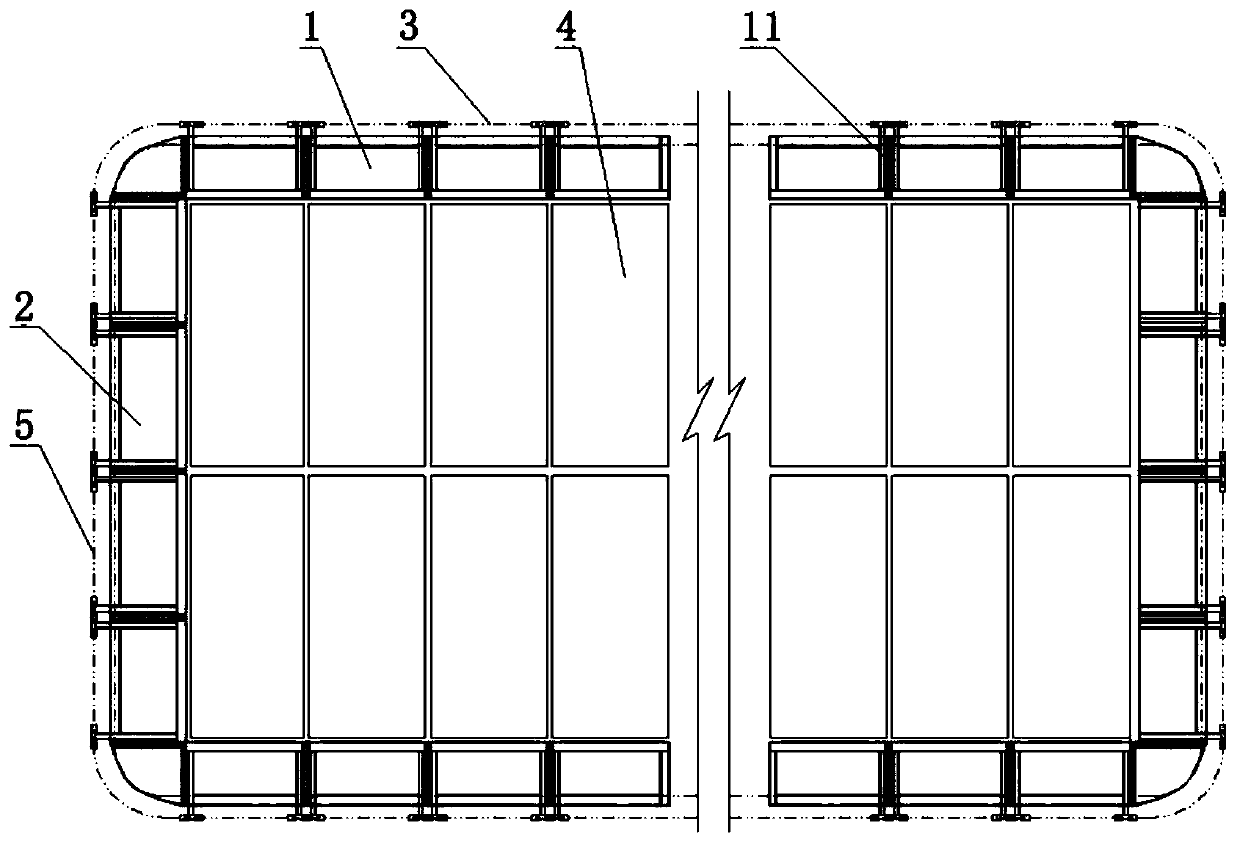

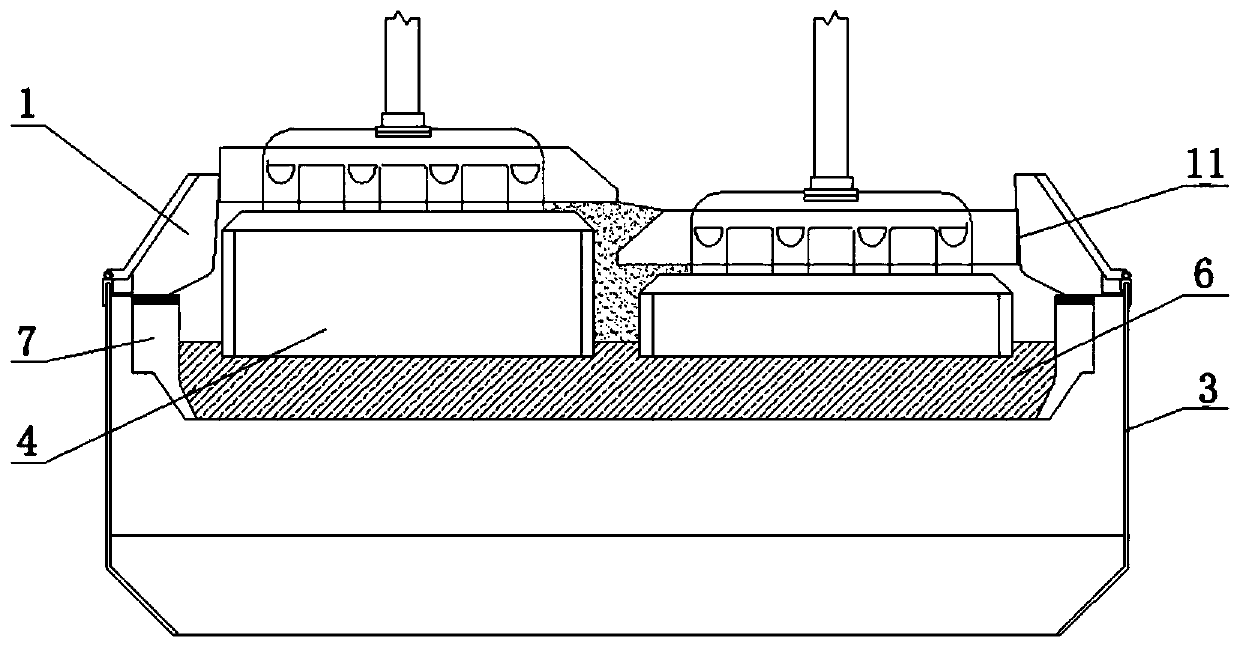

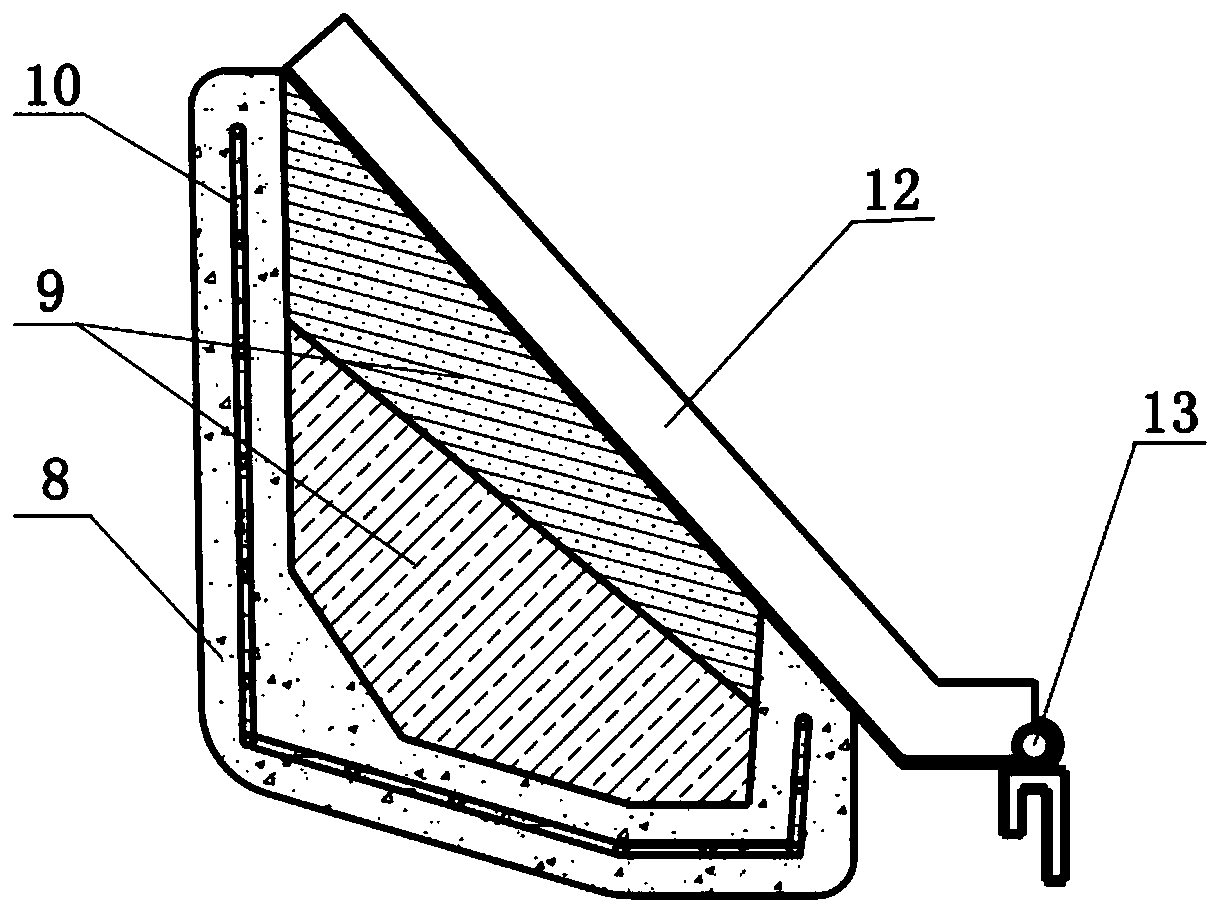

[0024] like Figure 1-Figure 3 As shown, the covering method of the present invention is to arrange a plurality of integral parts along the inner side of the whole circle of the tank shell of the aluminum electrolytic cell to the outer side of the anode group, above the liquid level of the electrolyte 6 and the side grate, and below the tank cover plate. Formed thermal insulation composite covering device, a single composite covering device can be opened and closed independently, forming a complete set of furnace door-type thermal insulation covering device that completely covers the entire circumference of the tank shell, replacing the traditional side covering with electrolyte alumina mixed powder. In this way, the thermal insulation, gas collection and anti-oxidation functions of the existing powdery covering materials are integrated. like...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com