Automobile coating conveyor based on series-parallel hybrid mechanism

A hybrid mechanism and conveyor technology, applied in coating, electrolytic coating, electrophoretic plating, etc., can solve the problems of complex structure of RoDip conveyor and multi-functional shuttle, difficult to meet flexible production requirements, and high maintenance cost. Achieve the effect of easy modular production, saving investment and operating costs, and improving load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

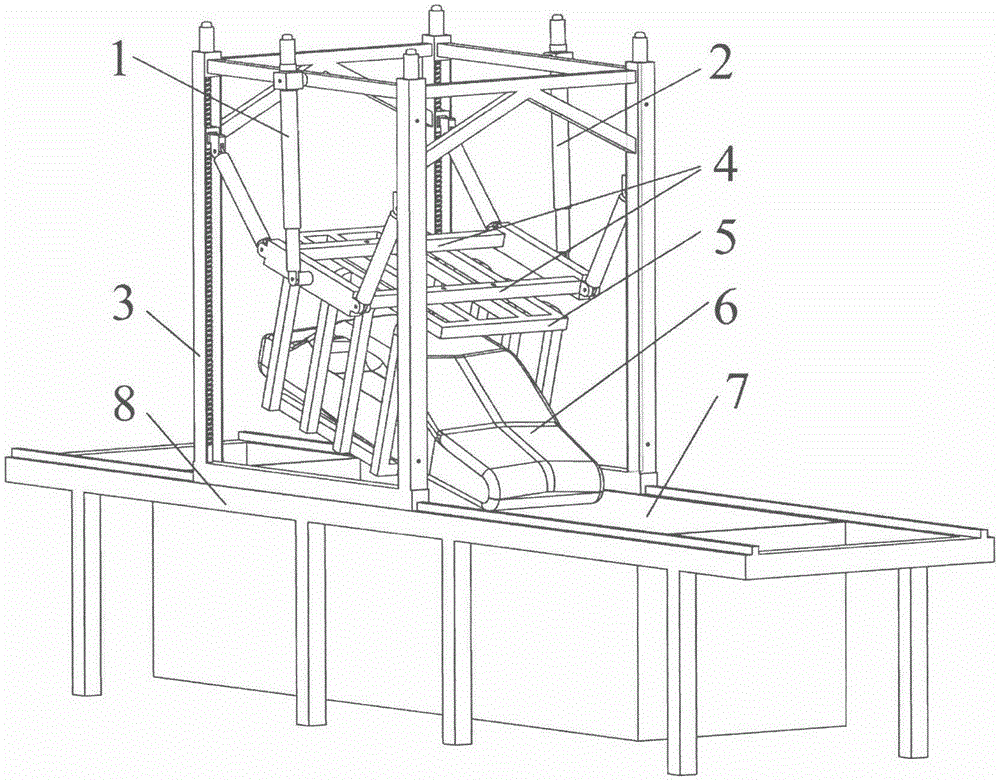

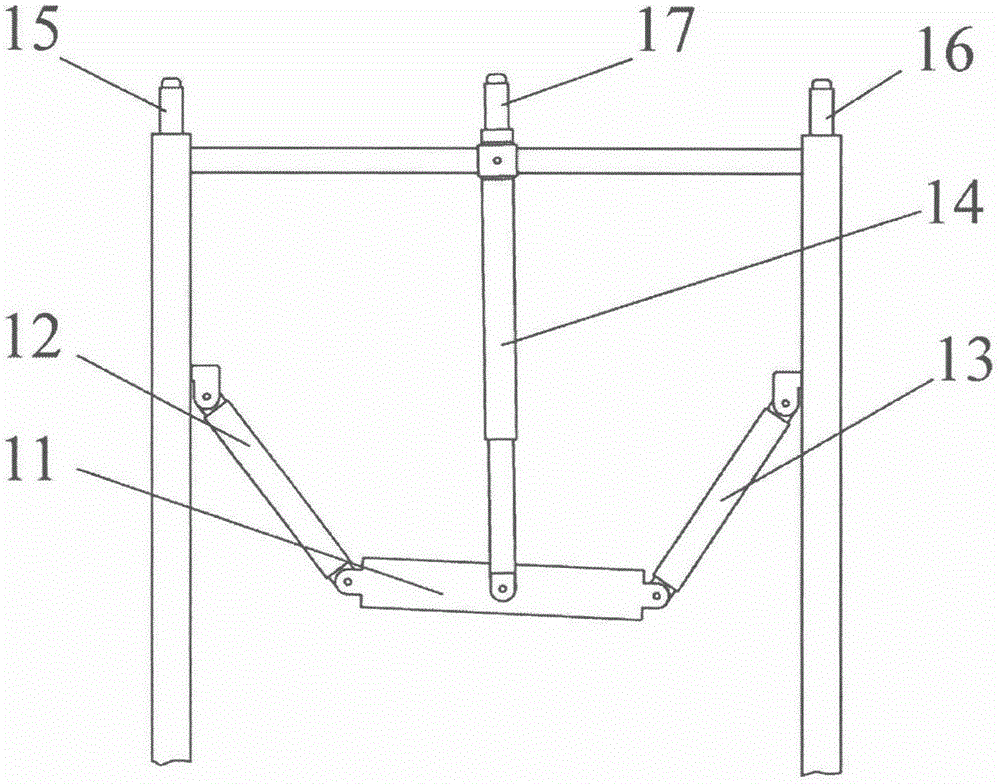

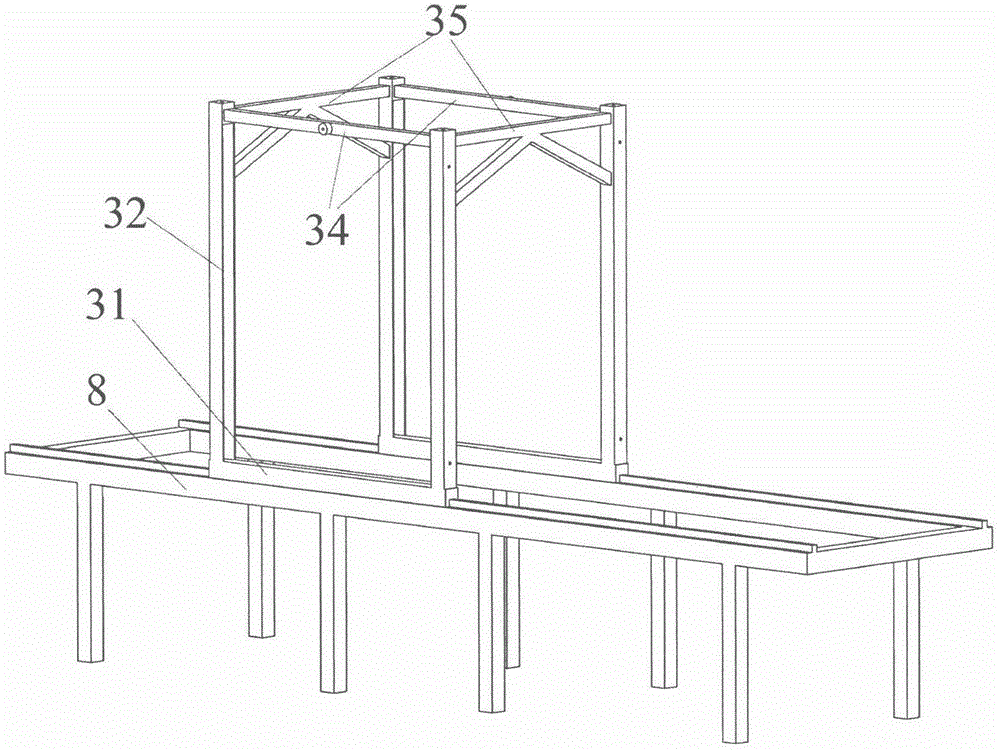

[0021] The structure of an embodiment of the automobile coating conveyor based on the series-parallel mechanism of the present invention is as follows: figure 1 As shown, the conveyor of the present invention includes two functional parts of a gantry frame 3 and a parallel conveying mechanism installed on the gantry frame 3, and the parallel conveying mechanism includes a first parallel mechanism 1 and a second parallel mechanism 2, The two parallel mechanisms are connected into one body through the connecting rod 4, and are symmetrically arranged on the gantry frame 3; the car body support 5 is installed on the connecting rod 4, and the car body 6 to be processed is fixed on the car body support 5; The movement of the car body 6 is controlled when it enters and exits the electrophoresis tank 7. Since the patent of the present invention utilizes the advantages o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com