Hydraulic self-elevated truss-type cantilever heavy arch dam mould system

A truss type and formwork technology, which is applied in the direction of arch dams, dams, buildings, etc., can solve the problems of slow project progress and low efficiency, and achieve the effects of improving pouring efficiency, ensuring safety, and shortening the construction period of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

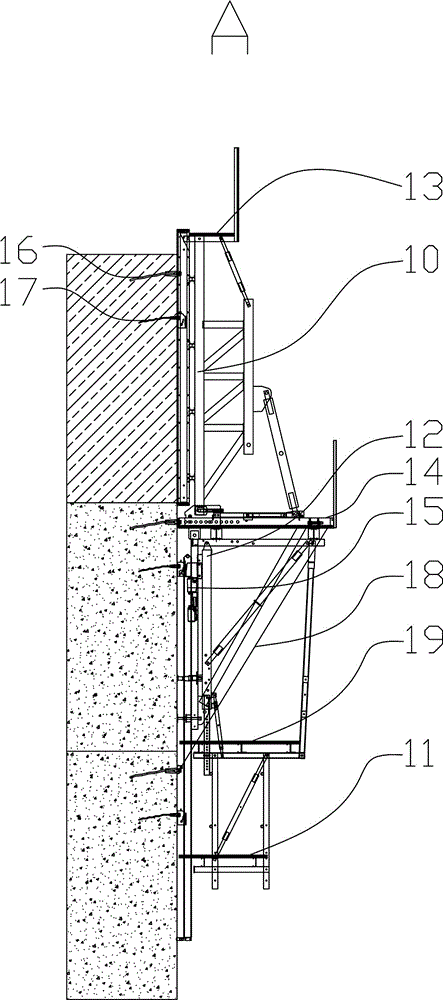

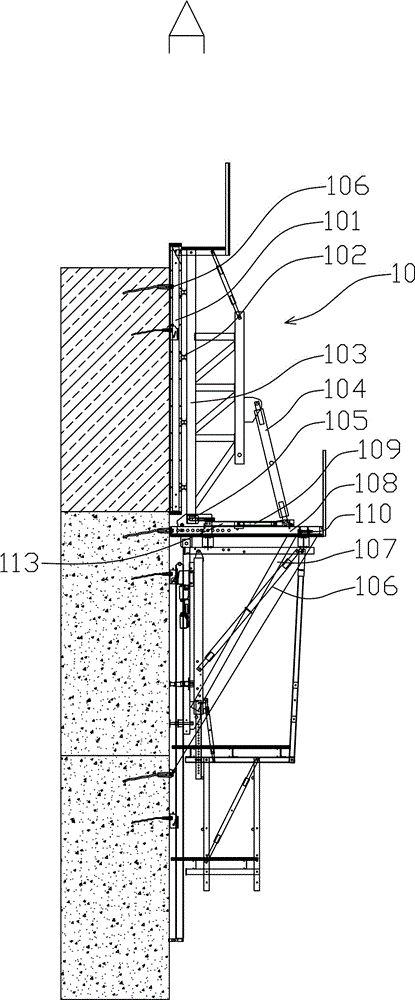

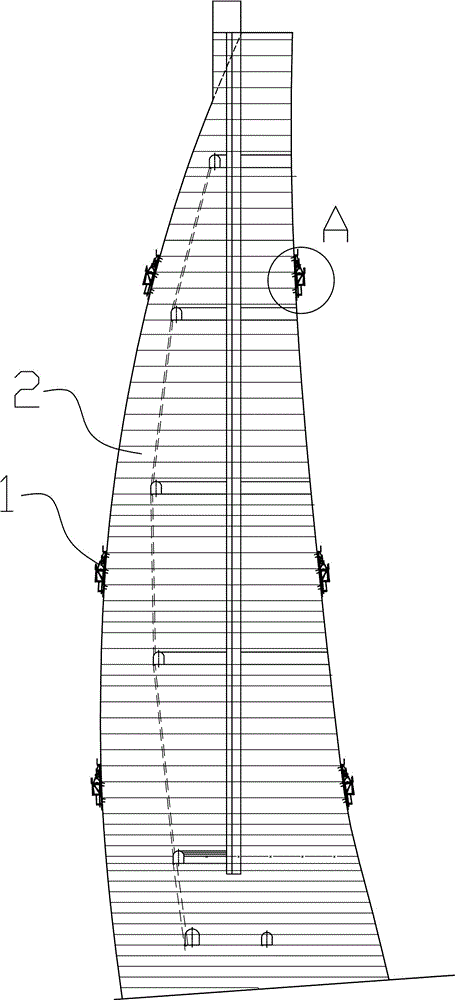

[0038] Such as Figure 1-12 Among them, a hydraulic self-elevating truss type cantilever heavy-duty arch dam formwork system includes a stressed tripod 107, a hydraulic climbing frame system 15 connected with the stressed tripod 107, and the stressed tripod 107 consists of a horizontal bar and a vertical bar It is composed of a fixed connection with a diagonal bar, and the cross bar is located at the top, such as figure 1 , 2As shown in , the hydraulic climbing frame system 15 connected with the stressed tripod 107 is provided with a plurality of hanging shoes for connecting with anchor cones, H-type climbing frame guide rails and climbing frame hydraulic cylinders 152. The frame system is prior art, for example, the frame system described in Chinese patent document CN 102345381 A.

[0039] Formwork device 10 is movably installed on the stressed tripod 107; described stressed tripod 107 is multiple, and stressed tripod 107 and formwork device 10 are arranged along the const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com