Construction method of filling gaps on top of filler wall

A construction method, a technology of filling walls, applied in the direction of construction, building construction, etc., can solve problems such as cracks, achieve the effects of solving easy cracks, improving construction quality, and being easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

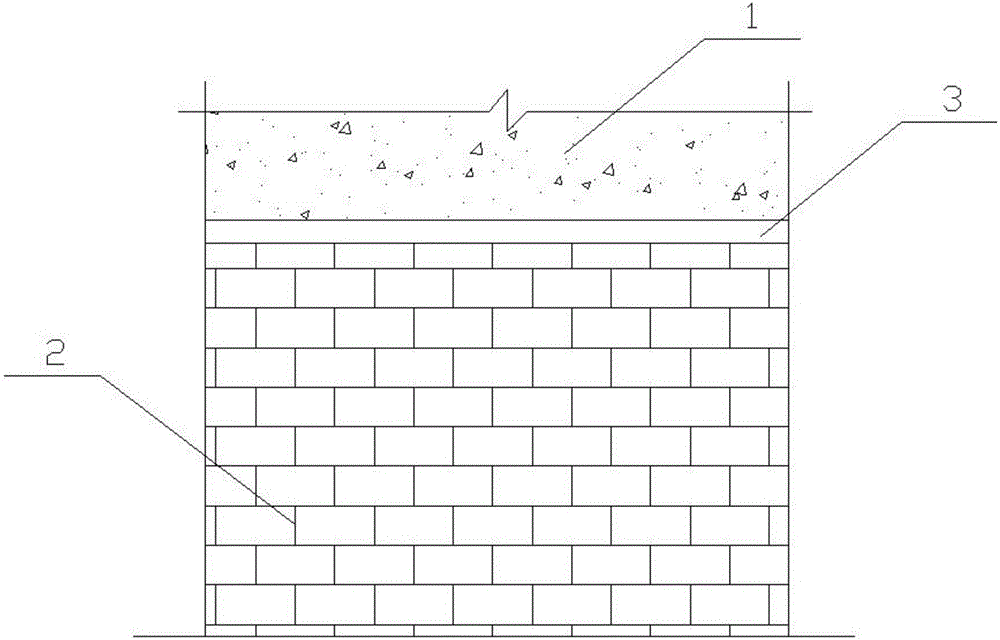

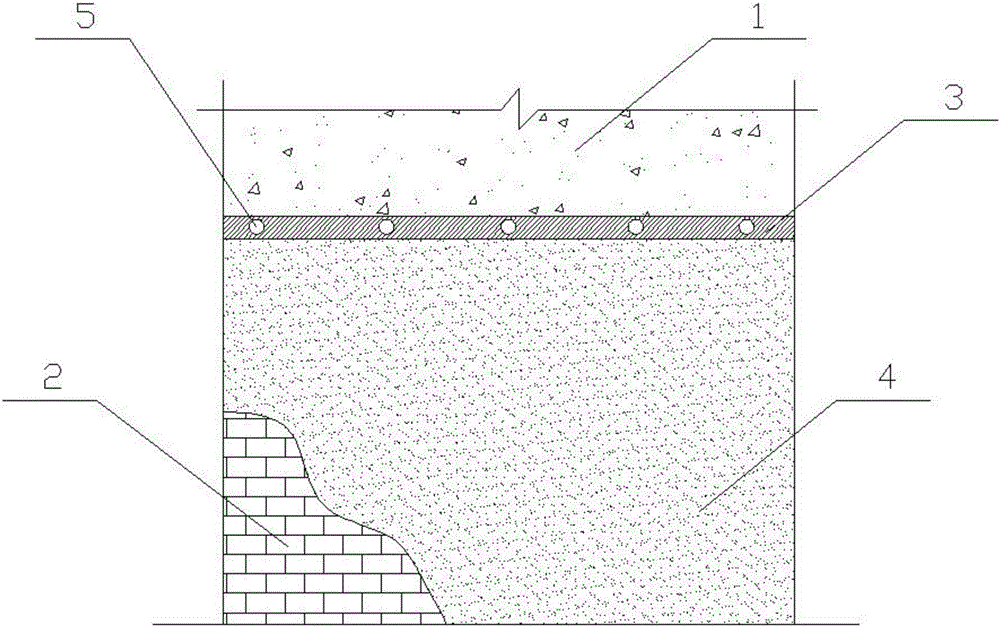

[0025] Such as figure 1 , figure 2 , image 3 As shown, the construction method of plugging joints at the top of the filling wall is characterized in that a certain gap 3 is reserved when the filling wall 2 is built to the bottom of the concrete structural beam or slab; Tighten the inner side of the wall to give a pre-pressure to the top of the masonry; use fine stone concrete to fill the gap on the outside of the top of the wall to ensure that the dry hard fine stone concrete or cement mortar can fill the gap tightly; wait for the outer fine stone concrete After the strength reaches 50%, remove the anti-corrosion wooden wedge 6, fill the inner side of the wall with fine stone concrete, and embed grouting pipes 5 at intervals; Cement mortar; specific implementation steps include:

[0026] Step 1. When the filling wall 2 is built close to the bottom of the concrete structural beam or slab 1, a gap 3 is left. After the filling wall 2 is built and at least 15 days apart, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com