Metal net structure used for roof hanging tiles

A technology of metal mesh and hanging tiles, which is applied to roofs, roofs using tiles/slate tiles, roof coverings, etc., can solve the problems of cumbersome construction steps, increased roof loads, and low work efficiency, and achieve fast installation and disassembly , Improve construction efficiency and facilitate adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

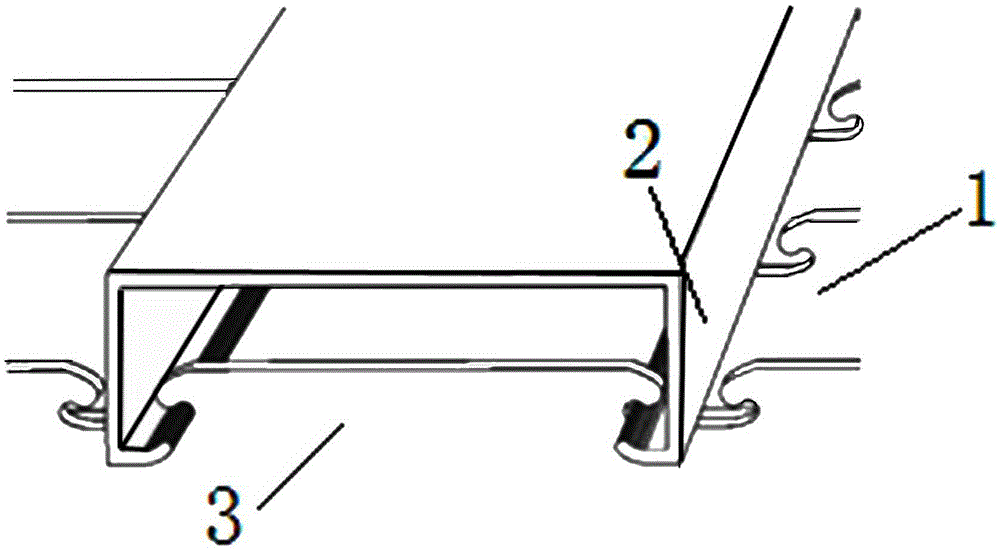

[0021] refer to figure 1 -3, a metal mesh structure used for roof tiles, including a concave-type smooth water strip 1 and a gusset-type tile-hanging strip 2, the concave-type smooth-flow strip 1 is on the bottom, and the gusset type tile hanging strip 2 is on the top, and the two are vertically fastened .

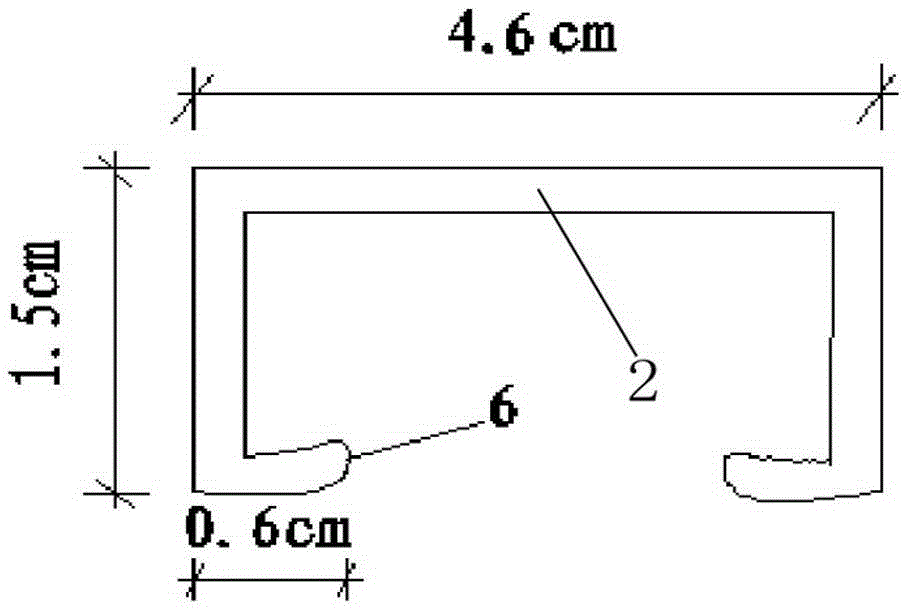

[0022] The gusset type hanging tile strip 2 is groove-shaped, and the upper parts of the notches on both sides are folded back inward to form a card edge 6. The angle of the card edge 6 is 65°, and the length of the fold is 0.6cm. The front end of the card edge is arc-shaped and faces Bottom curved.

[0023] The groove width of the gusset type hanging tile 2 is 4.6cm, and the height is 1.5cm.

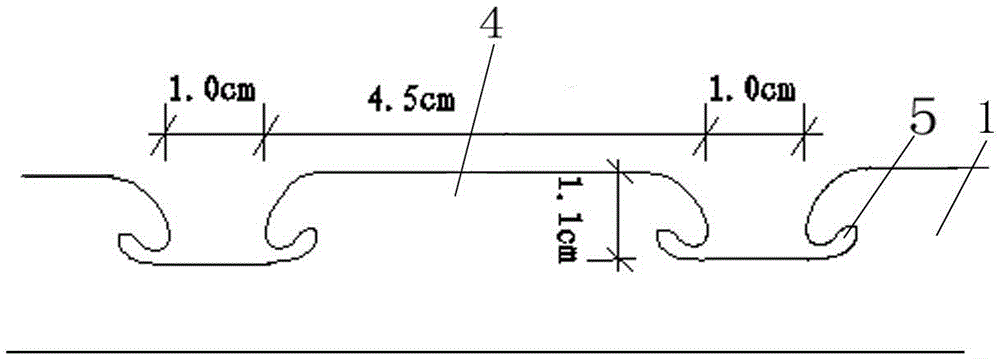

[0024] The concave-type downstream strip 1 is a structure with a wide top and a narrow bottom. The width of the upper wide mouth is 2.0 cm, the width of the lower narrow mouth is 1.5 cm, and the height of both sides is 2.0 cm.

[0025] There are T-shaped teeth 4 at equal interval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com