A Self-calibration Shadow Moiré 3D Profile Measurement Method

A measurement method and technology of three-dimensional profile, applied in the direction of measuring devices, instruments, optical devices, etc., to achieve the effects of saving measurement time, simplifying the technical level, and accurate calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

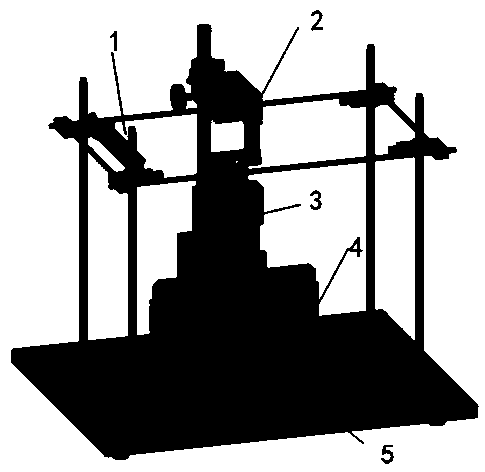

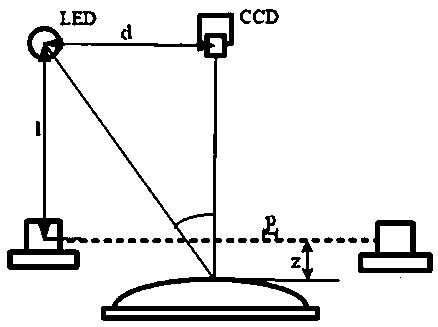

[0050] see figure 1 and figure 2 , the device used in the present invention is a conventional device, including a CCD camera 2, a line light source 1, a grating 4 and a motorized translation stage 3, the optical axis of the CCD camera 2 is perpendicular to the grating surface, and the center of the light source of the CCD camera 2 and the line light source 1 is placed The distance from the plane L where the grating 4 is located, the distance between the line light source 1 and the center of the CCD camera 1 is d.

[0051]During measurement, the object to be measured 5 is set at the measurement position. A self-calibration shadow moiré three-dimensional profile measurement method, comprising the following steps in sequence:

[0052] Step 1: Place the measured object in the measurement space, turn on the light source, and use the camera to record the resulting fringe pattern. Specifically, place the workpiece in the measurement space and initialize it through the virtual inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com