A Measuring Method for Improving the Precision of Multi-Dimensional Finishing

A measurement method and multi-dimensional technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of disassembly and assembly of measuring machines, inconvenient handling, and bulky 3D measuring machines, and achieve the effects of reducing deformation, lightening total weight, and light handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

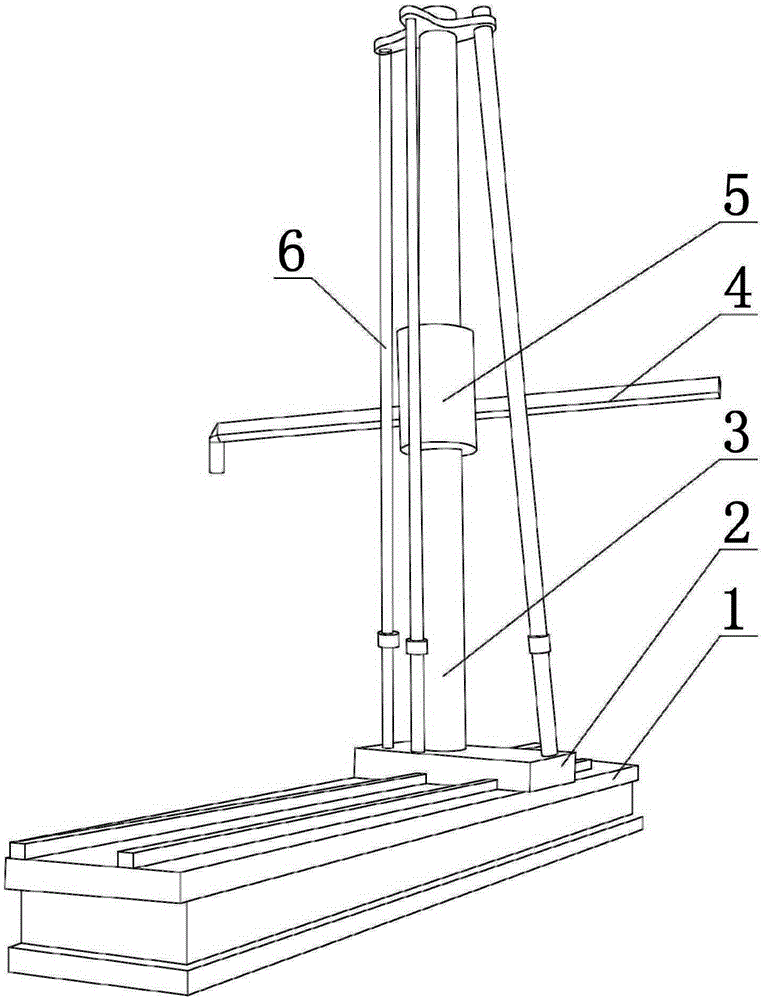

[0023] Such as figure 1 As shown, a measurement method for improving the accuracy of multi-dimensional finishing, including a base 1 provided with a slide rail, a sliding seat 2 arranged on the upper surface of the base 1 and engaged with the slide rail, fixed on the sliding seat 2 The vertical bar 3 on the top, the lifting part 5 that is sleeved on the vertical bar 3 and can move up and down along the length direction of the vertical bar 3, and the horizontal bar that is arranged on the lifting part 5 and can extend out in length relative to the lifting part 5 4. Any one end of the cross bar 4 is provided with a measuring head, and also includes a plurality of pull rods 6, the upper ends of the pull rods 6 are fixedly connected with the cross bar 4, and the lower ends of the pull rods 6 are all fixed on the sliding seat 2, and The pull rods 6 are annularly arranged around the vertical rod 3; the pull rods 6 are two-section combined structures, at least one section of each pu...

Embodiment 2

[0028] The present embodiment is further limited on the basis of embodiment 1, as figure 1 As shown, in order to enable the pull rod 6 to serve the whole of the vertical rod 3 , the connection points between the pull rod 6 and the vertical rod 3 are located at the upper end of the vertical rod 3 .

[0029] As an implementation method that can reduce the weight of the vertical rod 3 and the pull rod 6 under the condition of satisfying the respective strengths of the vertical rod 3 and the tie rod 6, the vertical rod 3 and the tie rod 6 are all conical with the upper end diameter smaller than the respective lower end diameter pole.

[0030] As a structural form of the vertical rod 3 and the tie rod 6 that is convenient to obtain greater rigidity under the same material consumption, the vertical rod 3 and the tie rod 6 are both hollow structures.

Embodiment 3

[0032] This embodiment is further defined on the basis of any one of the solutions provided in the above embodiments, as a realization of the cross bar 4 that has good resistance to bending deformation under the same amount of material, and the cross bar 4 is vertical The longitudinal cross-section in its length direction is a rectangle whose width is smaller than the height.

[0033] As a further implementation of the cross bar 4 which has good resistance to bending deformation under the same material consumption, the cross bar 4 is a hollow bar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com