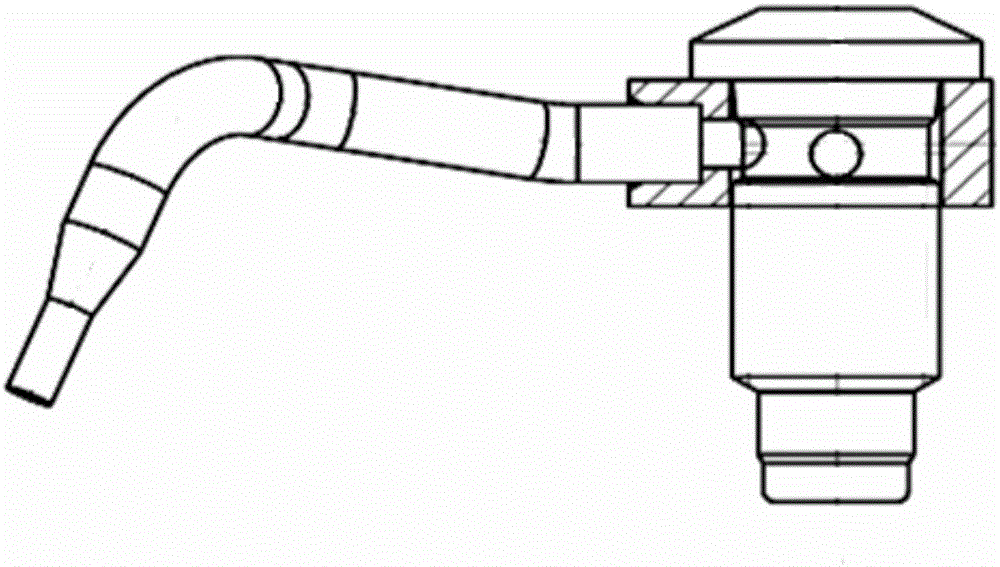

Piston cooling nozzle automatic measuring device

A technology for piston cooling nozzles and automatic measurement, which is applied in the direction of measuring devices, by measuring the rate of increase and deceleration of fluid, and using liquid/vacuum degree for liquid tightness measurement, etc., which can solve the problems of low detection accuracy and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

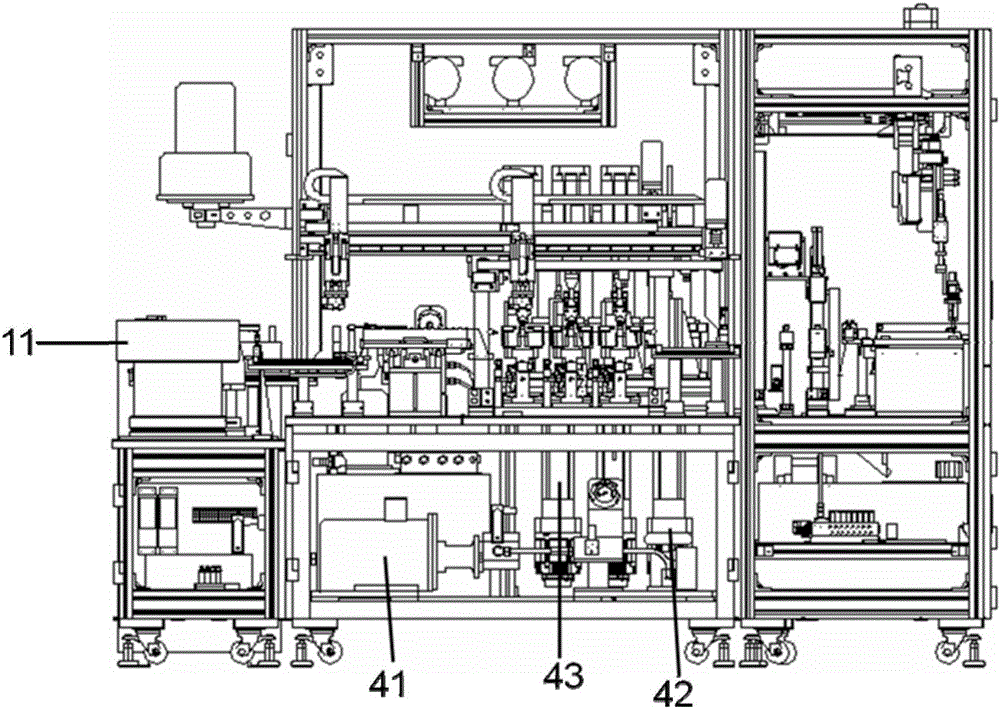

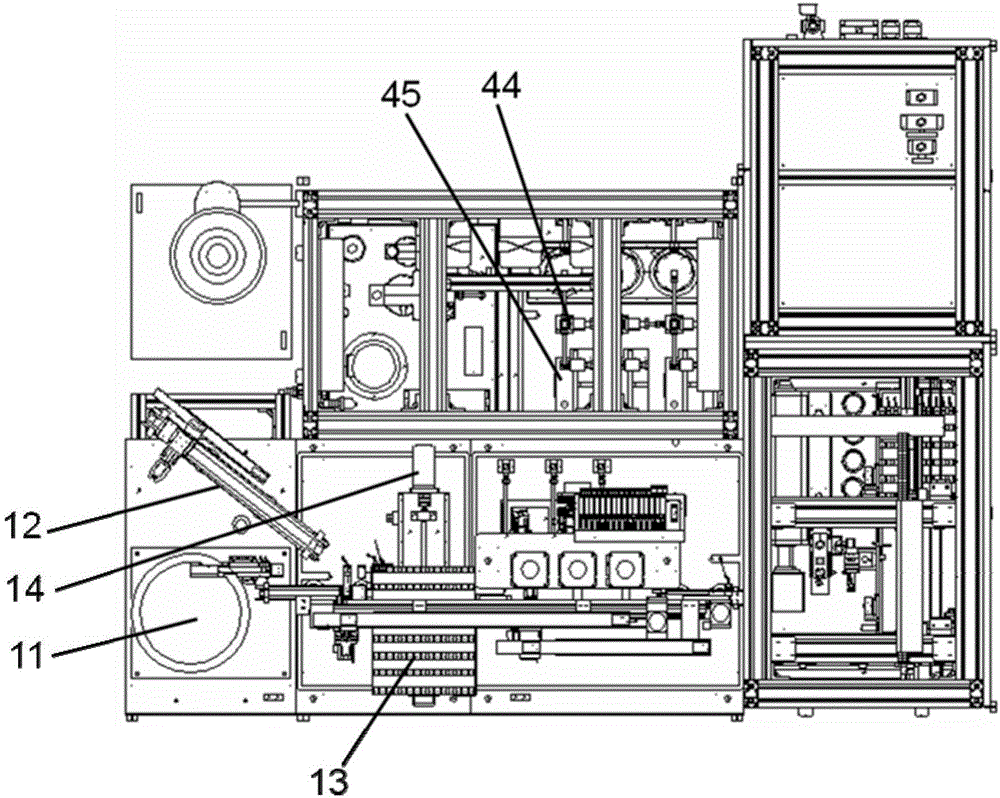

[0029] see below Figure 2 to Figure 9 The automatic measuring device for the piston cooling nozzle of the present invention is described in detail.

[0030] The automatic measuring device for piston cooling nozzles of the present invention has a frame-like main bracket for supporting and installing together, on which a feeding system for placing the workpiece to the measuring station is mainly provided for placing The blanking system that removes the workpiece from the measuring station and performs specific treatment on it, the oil supply system that provides the oil body that meets the measurement requirements for the measuring process of the workpiece, and the workpiece positioning used to position the workpiece to the measuring station system, a workpiece detection system used to measure the relevant performance parameters of the workpiece, and an intelligent control system used to control the working status of the aforementioned systems and perform data transmission. sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com