Method for measuring crosslink density of elastomer

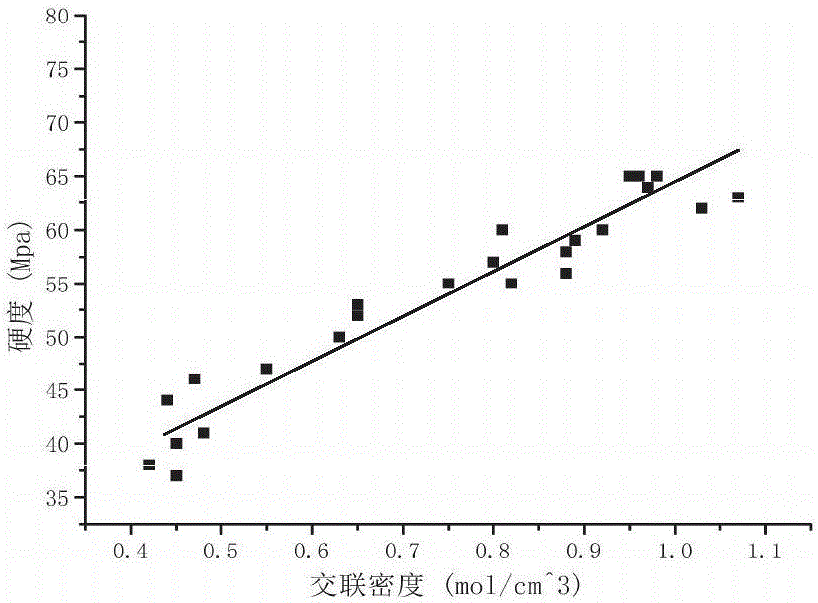

A cross-linking density and elastomer technology, which is applied in the analysis of nuclear magnetic resonance, can solve the problems of cross-linking density difference, poor correlation between cross-linking density and mechanical properties, and achieve the effect of improving accuracy and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Measuring the crosslink density of Thai standard gum

[0036] (1) Preparation of vulcanized rubber

[0037] The rubber is selected as Thai standard rubber, and the raw rubber is plasticized on the XK-250 open mill (Shanghai Rubber Machinery No. Black, finally add sulfur of different components, make a triangular bag, park it for 4 hours, and vulcanize it with an XLB-D flat vulcanizer (Huzhou Shunli Rubber Machinery Co., Ltd.). When the time is 5min, 7min, 8min and 10min, the rubbers with different degrees of vulcanization are taken out respectively. Cut the prepared fluidized rubber into strips of 0.1*0.1*1cm, wrap the three rubber strips with polytetrafluoroethylene for nuclear magnetic experiment

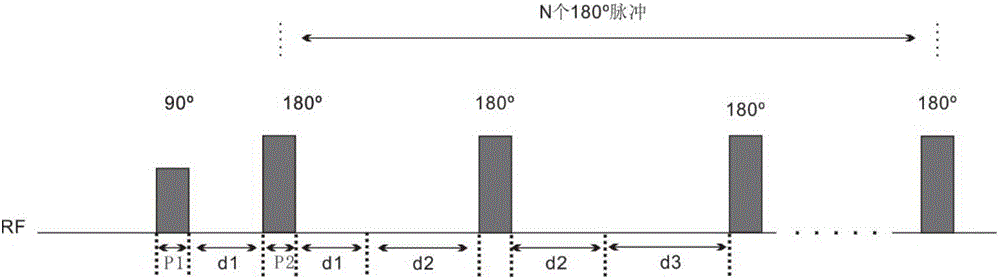

[0038] (2) Adopt nuclear magnetic resonance cross-linking density meter to detect cross-linking density

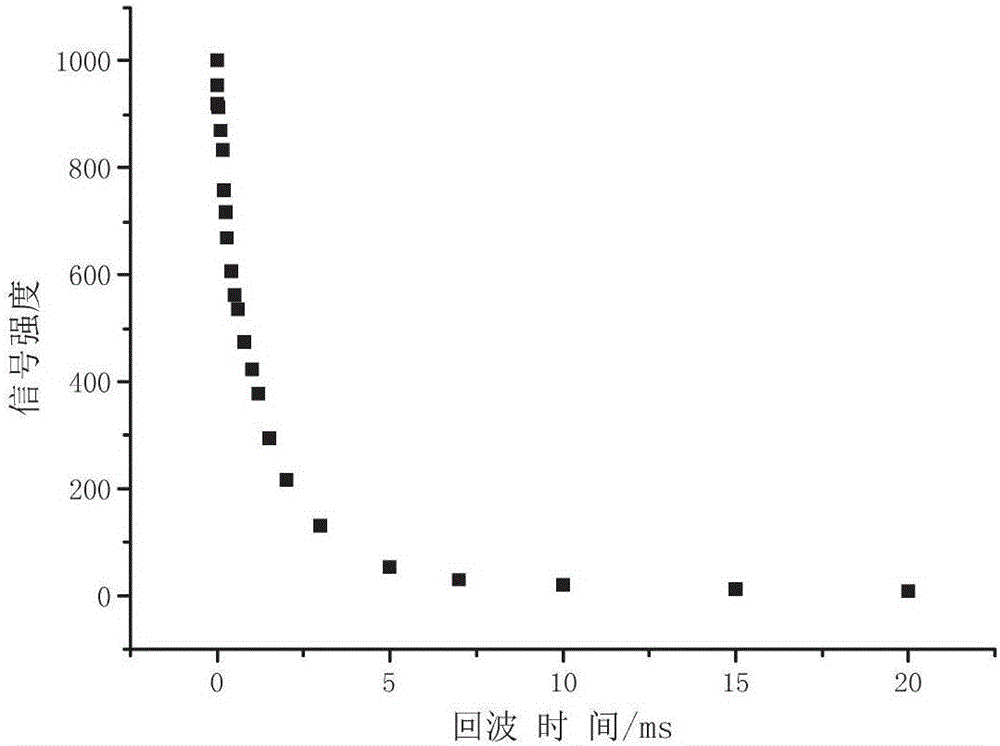

[0039] NMRC12-010V-T crosslinking density tester (Shanghai Numai Electronic Technology Co., Ltd.) was used to measure the nuclear magnetic parameters of the vulcaniz...

Embodiment 2

[0046] Others are identical with embodiment 1, and difference is the parameter of controlling nuclear magnetic resonance cross-linking densitometer: echo time is arranged from small to large, and echo time arrangement obeys logarithmic function, and the expression of logarithmic function is f(x )=a|log b x, the arrangement of the echo time is selected by changing the values of a and b in the implementation. In this example, a=14.66, b=5, and the value of x is 1.01~1.39, increasing by 0.01 each time. For the arrangement of the specific echo time, see Table 1, the measured crosslink density is well correlated with the mechanical properties.

Embodiment 3

[0048] Others are identical with embodiment 1, and difference is the parameter of controlling nuclear magnetic resonance cross-linking density instrument: echo time is arranged from small to large, and echo time arrangement obeys exponential function, and the expression of exponential function is f (x)= a*b x In practice, the arrangement of echo times is selected by changing the value of a. In this example, a=0.05 and b=4. For the arrangement of specific echo times, see Table 1. The measured crosslink density is well correlated with mechanical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonance frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com