Temperature difference type wind speed sensor, preparation method thereof and wind speed detecting method

A wind speed sensor and wind speed detection technology, which is applied in the direction of measuring fluid speed by using thermal variables, can solve problems such as the complexity of structural manufacturing processes, avoid bonding wire technology and substrate through-hole technology, have a simple structure, and solve lead problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

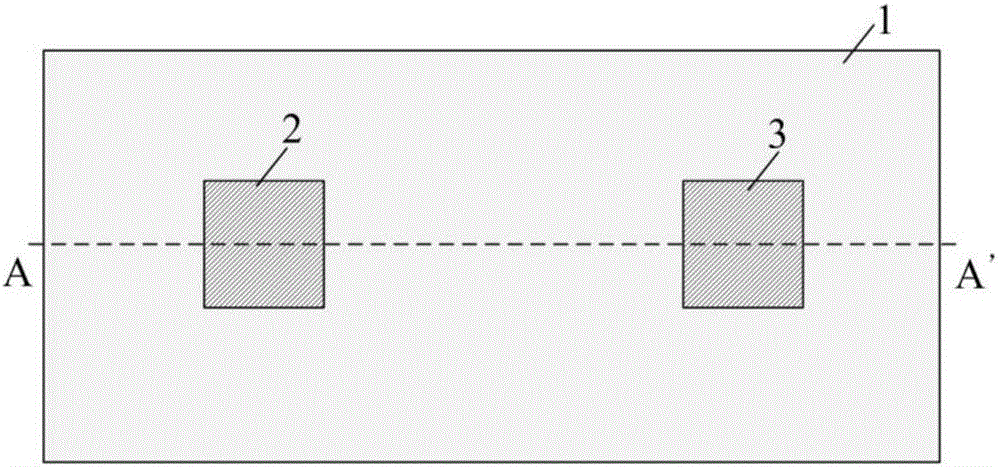

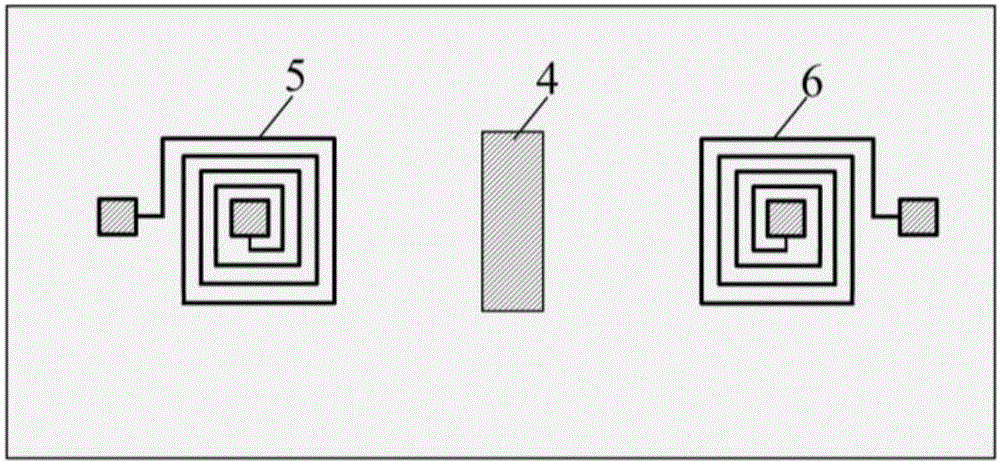

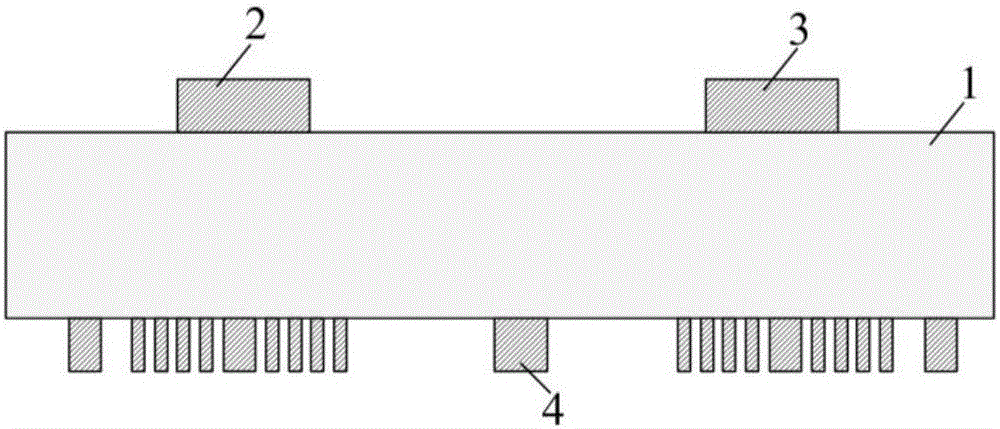

[0035] see figure 1 , figure 2 and image 3 , the thermal temperature difference wind speed sensor and its detection method provided by the present invention, the wind speed sensor includes a ceramic substrate 1, a heating resistor 4, temperature sensing metal blocks 2 and 3, and temperature measuring inductance coils 5 and 6.

[0036] Wherein, the thermal conductivity of the ceramic substrate 1 can be less than 30; of course, theoretically speaking, there is no requirement for the thermal conductivity of the substrate, but in order to improve the sensitivity, it is best to use ceramics.

[0037] The heating resistor 4, that is, the heating element, is grown on the center of the back of the ceramic substrate 1, and the heating resistor 4 is heated by applying a direct current.

[0038] The temperature-sensing metal blocks 2 and 3, that is, the temperature-sensing e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com