Semiconductor structure laser lift-off method

A laser lift-off and semiconductor technology, used in semiconductor/solid-state device manufacturing, laser welding equipment, electrical components, etc., can solve the problems of panel packaging difficulties, lower yield, and lower yield, to improve product yield and improve stability. Sex, avoid the effect of bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

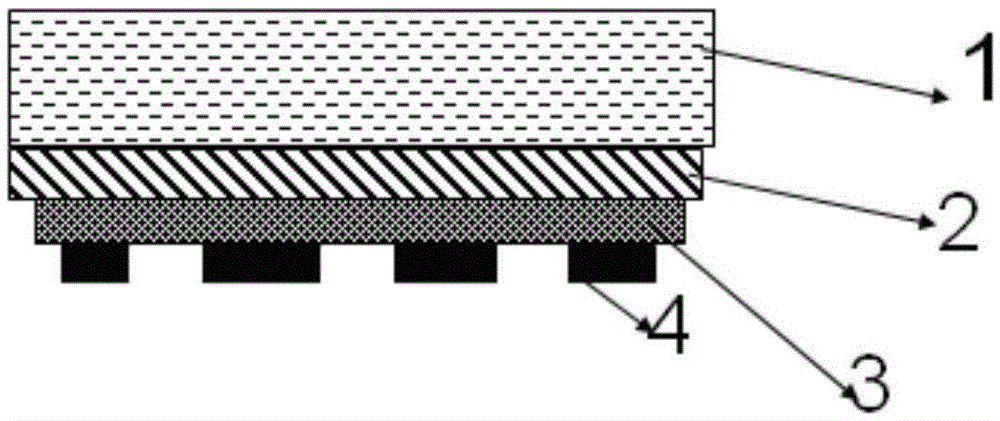

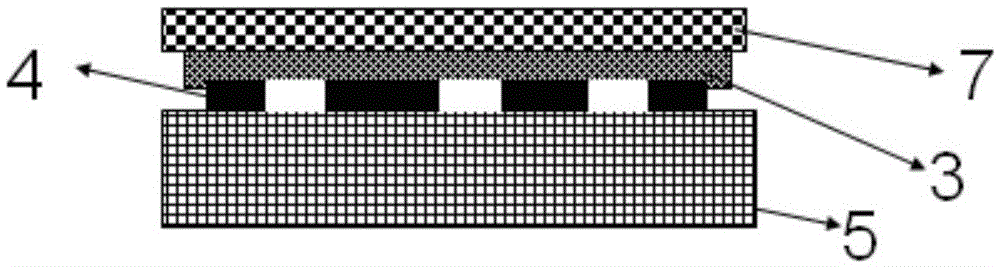

[0048] Enumerate a specific embodiment: such as Figure 3a-3d As shown, a semiconductor structure laser lift-off process, wherein: comprising the following steps:

[0049] A large plate glass substrate 10 is provided, and a polyimide film and packaging film layer 20 are sequentially deposited on the large plate glass substrate;

[0050] The large glass substrate 10 prepared with the polyimide film and the encapsulation film 20 on the surface is placed on a second working platform;

[0051] Attaching a sub-substrate-sized encapsulation film 10 on the surface of the water and oxygen blocking film 30 to form the semiconductor structure with an uneven surface;

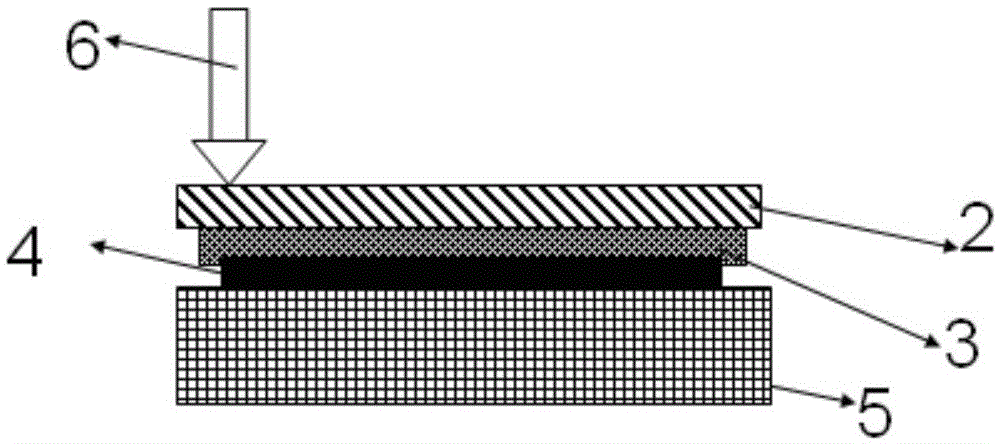

[0052] A plurality of protruding mechanisms 60 are fixedly arranged on the working surface 51 of the first working platform 50;

[0053] The semiconductor structure is placed on the first working platform 50, and the plurality of protrusion mechanisms 60 provided on the first working platform 10 fit with the uneven lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com