Heat dissipation device in electrical cabinet

A heat dissipation device and electrical cabinet technology, which is applied in the direction of electrical components, electrical equipment structural parts, cooling/ventilation/heating transformation, etc., can solve problems such as electricity accidents, affect the life and reliability of motors, and damage components, and achieve promotion Efficient effect of gas flow and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

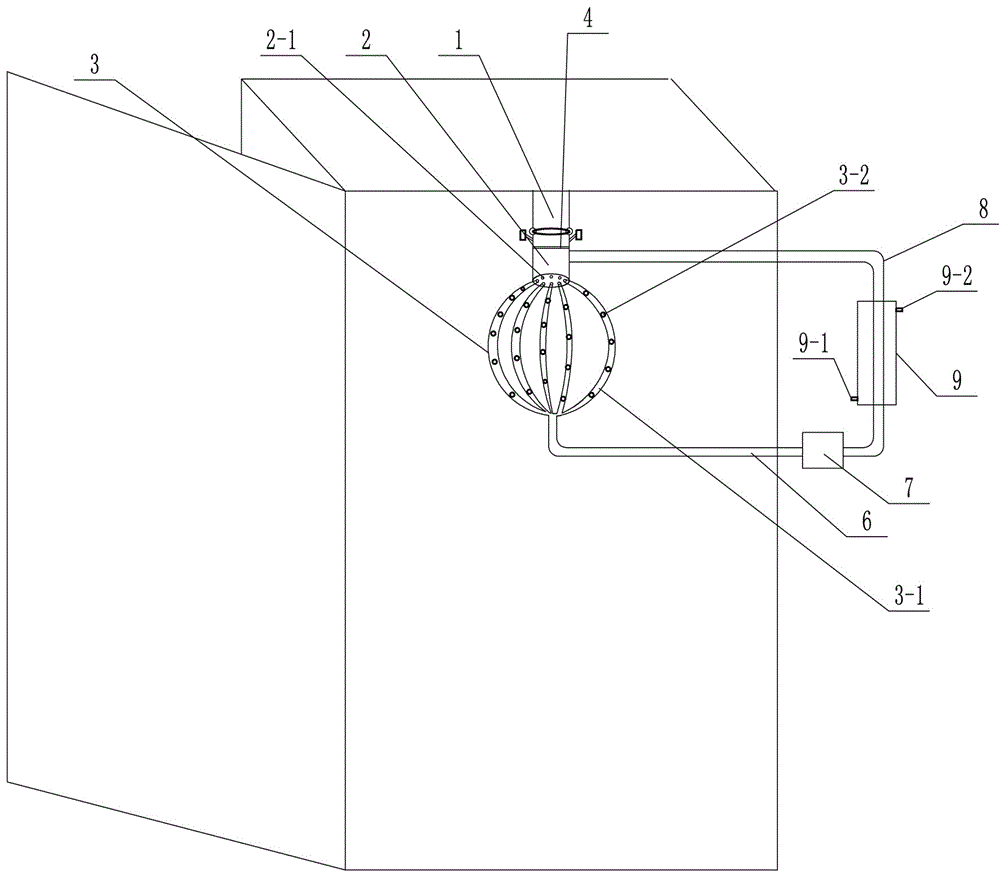

[0016] The invention includes a fixed pipe 1, a connecting pipe 2, a heat dissipation ball 3 and a gas circulation pipeline.

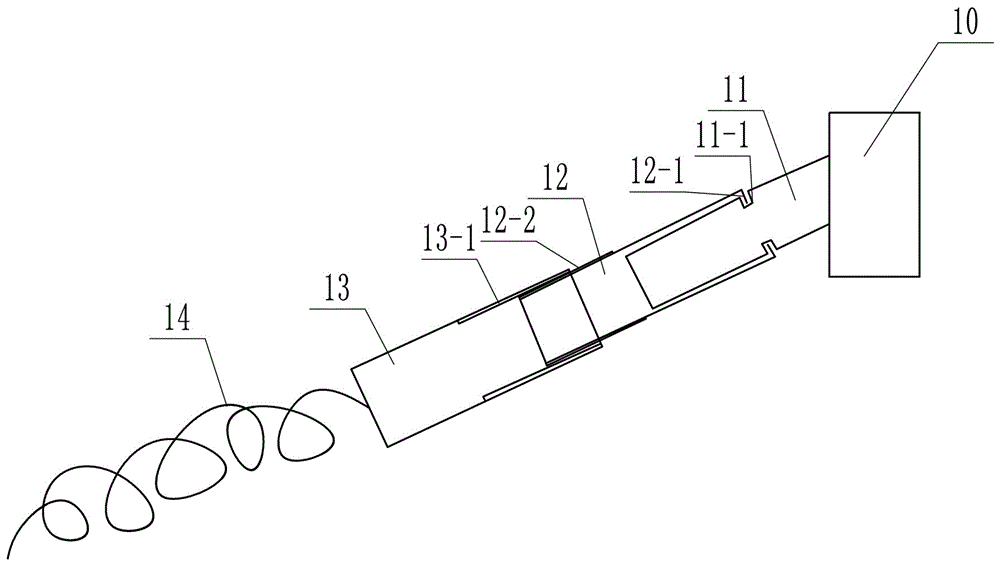

[0017] The top of the fixed pipe 1 is affixed to the top plate in the electrical cabinet, the bottom of the fixed pipe 1 is twisted with the top of the connecting pipe 2, and the connecting pipe 2 is provided with a partition 4, preferably , the partition plate 4 is located on the upper part of the connecting pipe 2, and the bottom of the connecting pipe 2 is uniformly provided with ventilation holes 2-1, and the ventilation holes 2-1 are evenly distributed on the floor plane at the bottom of the connecting pipe 2, the The heat dissipation ball 3 is located below the connecting pipe 2, and the heat dissipation ball 3 includes 3-20 arc-shaped heat dissipation pipes 3-1, and the heat dissipation pipes 3-1 are provided with heat dissipation holes 3-2, and the heat dissipation holes 3 -2 is uniformly dispersed on the outer surface of the heat dissipation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com