Method for quick desalting and alkalinity reducing of coastal heavy-viscidity saline soil

A saline soil and heavy clay technology, applied in the field of soil science, can solve problems such as the limitation of sustainable development of greening and poor soil quality, and achieve the effect of low cost of improvement, convenient operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

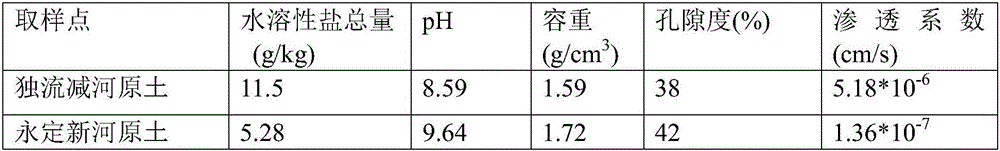

[0025] In 2015, this method of desalination and alkali reduction was applied in the "Binhai New Area Duliujian River and Yongding Xinhe Raw Soil Improvement Project". This project is a raw soil improvement project. The resulting saline soil has high salt content, heavy soil quality and poor structure, as shown in Table 1. The specific implementation steps are as follows:

[0026] Table 1: Soil physical and chemical indicators on March 23 before construction in 2015

[0027]

[0028] The inventive method comprises the steps of:

[0029] 1).Salt drainage in the project: According to the design, lay reverse planing grooves and bury salt drainage pipes. The distance between the pipes is 4 meters, and the buried depth of the pipes is 1.0 meters.

[0030] 2) Add improvement reagents: the first step is to mix solid aluminum sulfate in the soil body, add and mix by 0.8% of the soil weight of the planting layer (according to the depth of 100cm), and use mechanical mixing to mix eve...

Embodiment 2

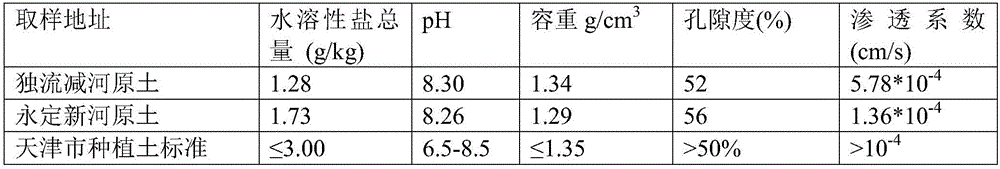

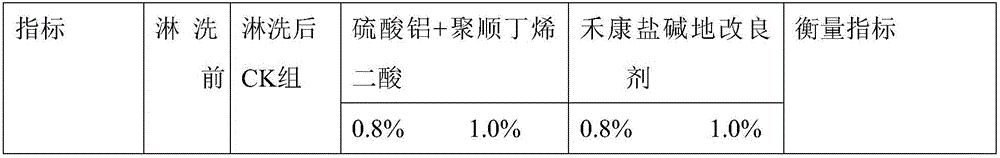

[0037] 1. Improved leaching experiment: We used plastic pots to fill saline soil, each pot weighed 900 grams, selected coastal saline soil, with a salt content of 2.14%, pH8.37, and set CK (the control was saline soil), and the concentration of aluminum sulfate was 0.8 %, 1.0%, polymaleic acid 0.6%, Hekang improver concentration 1.0%, 1.2%, a total of 5 treatments, each treatment repeated 5 times. The amount of reagents according to different treatments was evenly mixed with the soil and then filled into pots, with 900g of soil in each pot. After the soil sample is filled, the aluminum sulfate is solid and mixed according to the above dosage, and the other is liquid, weighed according to the dosage, diluted with water to 600mL and added to each pot to make the reagent fully react with the soil. After 12 hours of water drenching, measure the soil index and meet the requirements, see the table below.

[0038]2. Lawn sowing experiment: Sow 1g of ryegrass seeds per pot and observ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com