Jam filling machine

A filling machine and jam technology, applied in the fields of dough processing, baking, food science, etc., can solve the problems of inability to meet the needs of food enterprises, easily damaged particle slurry, low work efficiency, etc., achieving good sealing, convenient disassembly, The effect of gram uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

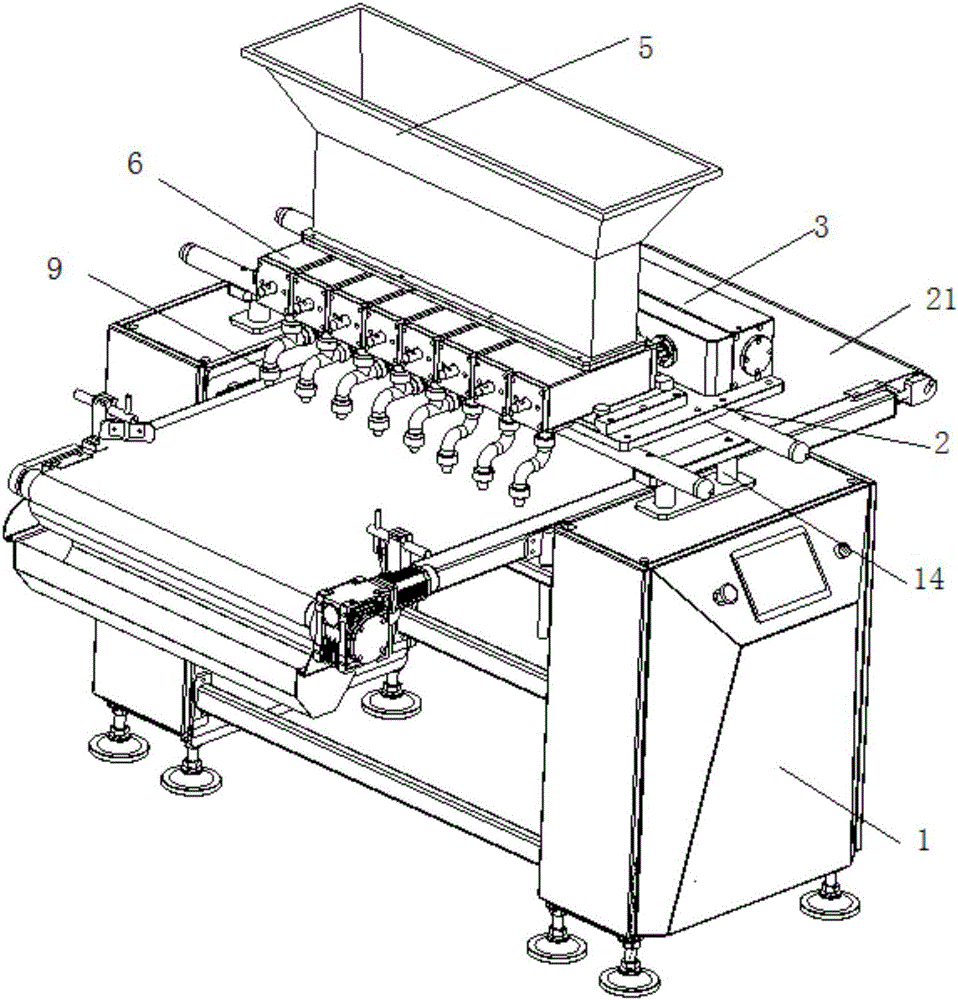

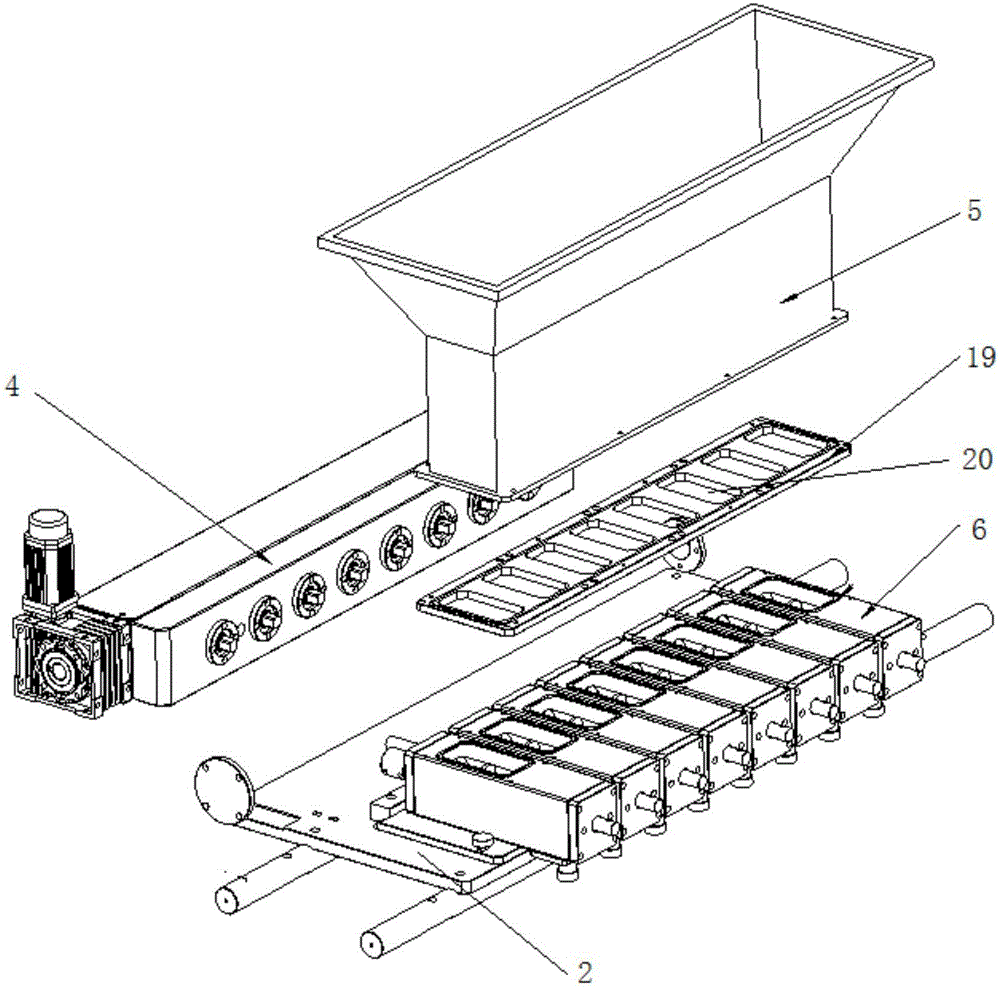

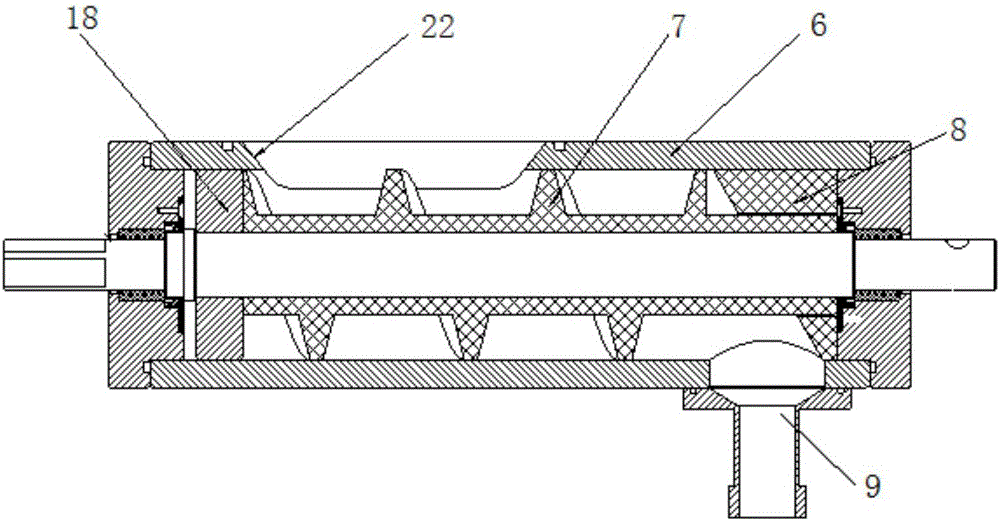

[0037] See attached picture.

[0038] A jam stuffing machine, characterized in that it includes a frame 1, a liftable support base 2 is installed on the frame 1, a pump body system 3 is installed on the support base 2, and the support base 2 is located on the pump body The rear side of the system is equipped with a power system 4; the pump body system 3 includes a master pump body, and a hopper 5 is sealed and connected to the master pump body; the master pump body includes a row of mutually independent sub-cylinder bodies 6, each All are provided with the feeding port 22 that communicates with the hopper, and the auger shaft 7 that is all rotatably installed in each sub-pump body, and the discharge end position that is positioned at auger shaft in each sub-pump body is all provided with deflector block 8, each The inner sides of each deflector block 8 are provided with a guide surface inclined inwardly, and each sub-pump body is provided with a discharge nozzle 9 at the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com