A high-efficiency and energy-saving rigid-flexible mixing impeller

A high-efficiency, energy-saving, stirring paddle technology, applied to mixers with rotating stirring devices, mixers, dissolving, etc., can solve the problem of "dead zone" of stirring, and achieve the goal of increasing turbulence, improving mixing efficiency, and strengthening the transfer process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

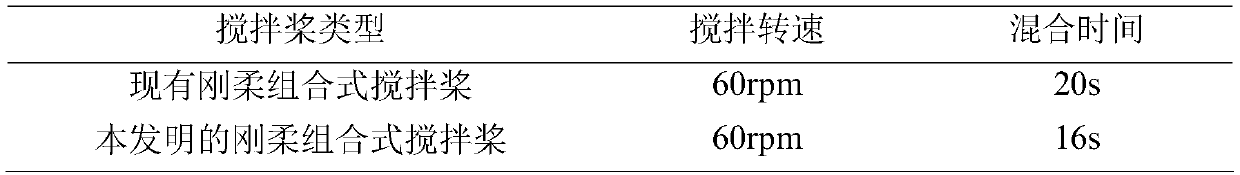

Embodiment 1

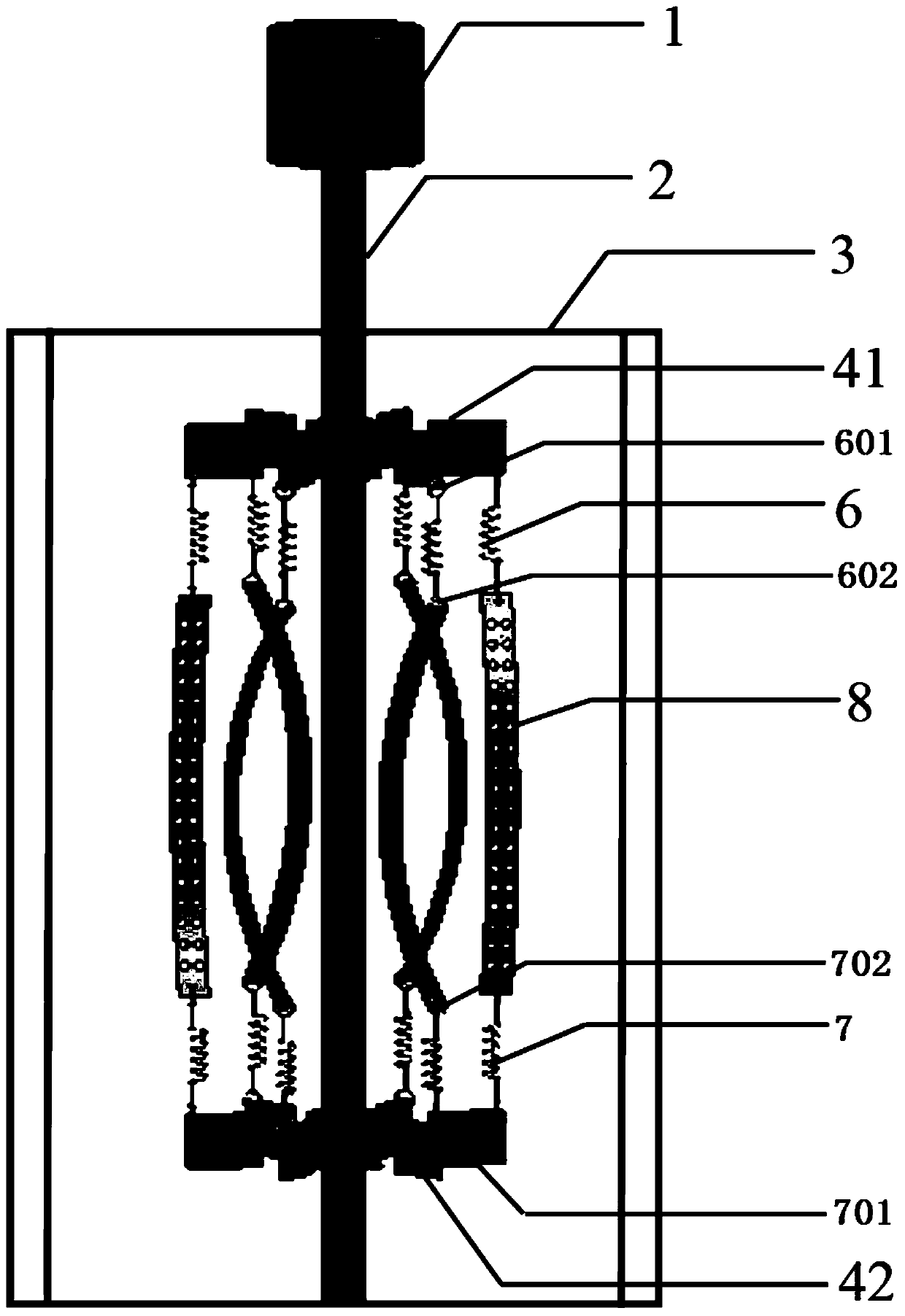

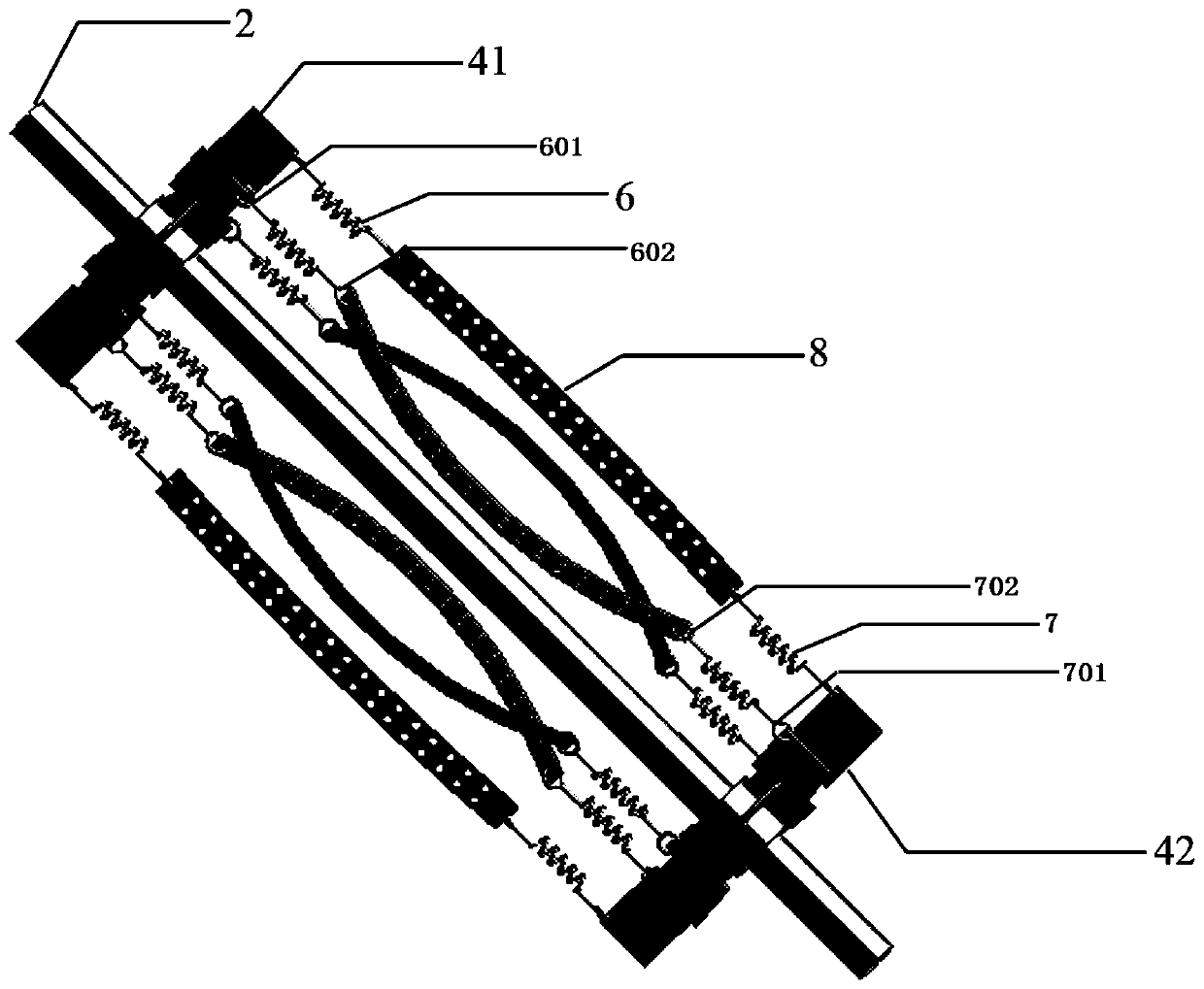

[0024] A high-efficiency and energy-saving rigid-flexible mixing paddle is characterized in that it includes a stirring shaft 2, a number of rigid paddles I41, rigid paddles II42, springs I6, springs II7 and perforated flexible sheets 8.

[0025] There are two nodes on the stirring shaft 2 . One of the nodes is connected with several rigid stirring blades I41, and these rigid stirring blades I41 form a rigid stirring blade I. Another node connects several rigid stirring blades II 42, and these rigid stirring blades II 42 form a rigid stirring blade II.

[0026] All the rigid stirring blades I41 are radially distributed around the stirring shaft 2 . The end of each rigid stirring paddle I41 is processed with a through hole, and a mounting ring I601 is passed through the through hole. A spring I6 is hung on each mounting ring I601, the spring I6 is a coil spring, and the metal rod at one end of the coil spring is bent into a hook shape (or ring shape); the spring I6 passes thr...

Embodiment 2

[0039] The main structure of this embodiment is the same as embodiment 1, further:

[0040] The diameters of the rigid stirring paddle I41 and the rigid stirring paddle II42 are equal. The paddle of rigid paddle I41 is the same size as the paddle of rigid paddle II42.

[0041] The width of the perforated flexible sheet 8 is 1 / 40-1 / 10 of the diameter D of the rigid paddle II42. It has been found through research that when the width of the perforated flexible sheet 8 is too narrow, it is beneficial for the perforated flexible sheet 8 to twist or shake, but the ability to transfer energy is poor; when the width of the perforated flexible sheet 8 is too wide, it is not conducive to Twisting or shaking, but the ability to transmit energy is strong. The width of the perforated flexible sheet 8 is d, and when d is 1 / 40-1 / 10 of D, the system can obtain a better mixing effect.

[0042] Further speaking, the distance between the lower edge of the blade of the rigid paddle I41 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com