Moving cutter shaft assembly of screen-free caustic soda pulverizer and screen-free caustic soda pulverizer

A pulverizer and moving knife shaft technology, applied in grain processing and other directions, can solve the problems of troublesome maintenance, high energy consumption and high production cost, and achieve the effect of reducing the use and maintenance cost, improving the delivery efficiency and improving the pulverization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

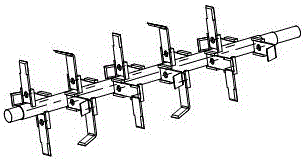

[0019] A moving knife shaft assembly of a caustic soda pulverizer without a screen, including a moving knife shaft 9 connected to the power device of the pulverizer, on which a plurality of knife seats are spirally arranged in the axial direction, and each knife seat is Detachably connected knives, the knives include straight knives 2 and curved knives 3, and the straight knives 2 and curved knives 3 are arranged alternately, and the curved knives 3 have an inclination angle of 40-50°.

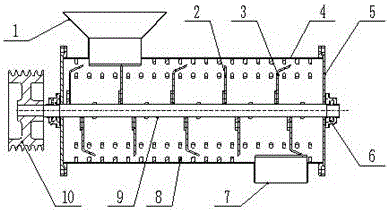

[0020] A caustic soda pulverizer without a screen, including a pulverizing device, the pulverizing device includes a casing 4 and a moving knife shaft assembly, the casing 4 includes a cylinder, and flanges are fixedly connected to both ends of the cylinder, and the flange is passed through The spigot is connected to the end cover 5, and the two ends of the movable knife shaft 9 are installed on the housing 4 through the bearing 6, and the housing 4 is provided with a material inlet 1 and a mat...

Embodiment 2

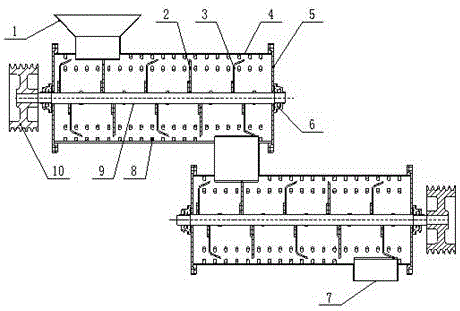

[0025] A caustic soda pulverizer without a screen, including two pulverizing devices, the pulverizing device includes a casing 4 moving knife shaft assembly, the two ends of the moving knife shaft 9 are installed on the casing 4 through bearings 6, and the casing 4 is provided with The feed port 1 and the discharge port 7, the discharge port 7 of the first crushing device is connected to the feed port 1 of the other crushing device.

[0026] This example is a further supplement to Example 1. If the particle size of the material does not meet the ideal requirements after being crushed by the first crushing device, the material crushed by the first crushing device is sent to the second crushing device for crushing again , until the required particle size is reached, wherein the pulverizer power unit includes a motor and a belt pulley assembly connected with the motor, and a pulley 10 of the belt pulley assembly is installed at the end of the moving knife shaft 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com