Method for short-term anti-corrosion treatment of automobile brake disc

A technology of automobile braking and anti-corrosion treatment, which is applied in the direction of pre-treatment surface, coating, and the device for coating liquid on the surface. Manufacturing cost, the effect of avoiding repair and derusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: a short-term anti-corrosion treatment method for automobile brake discs, comprising the steps of:

[0016] 1) Degrease and clean the brake disc of the car;

[0017] 2) Preheat the car brake disc in step 1) at 200°C for 30 seconds;

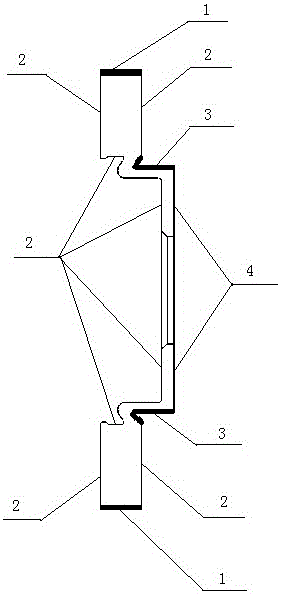

[0018] 3) Spray the large circle façade 3 of the automobile brake disc and the small circle façade 1 of the automobile brake disc in step 2) with Dacromet paint, the friction surface 2 of the automobile brake disc and the mating surface 4 of the automobile brake disc and the rim No spraying, then pre-bake at 180°C for 5 minutes;

[0019] 4) The automobile brake disc in step 3) was sintered and solidified at 390°C for 30 minutes, and then cooled naturally.

Embodiment 2

[0020] Embodiment 2: a short-term anti-corrosion treatment method for automobile brake discs, comprising the following steps:

[0021] 1) Degrease and clean the brake disc of the car;

[0022] 2) Preheat the brake disc of the car in step 1) at 180°C for 50 seconds;

[0023] 3) Spray the large circle façade 3 of the automobile brake disc and the small circle façade 1 of the automobile brake disc in step 2) with Dacromet paint, the friction surface 2 of the automobile brake disc and the mating surface 4 of the automobile brake disc and the rim No spraying, then pre-bake at 200°C for 8 minutes;

[0024] 4) The automobile brake disc in step 3) was sintered and solidified at 400°C for 35 minutes, and then cooled naturally.

Embodiment 3

[0025] Embodiment 3: a short-term anti-corrosion treatment method for automobile brake discs, comprising the following steps:

[0026] 1) Degrease and clean the brake disc of the car;

[0027] 2) Preheat the brake disc of the car in step 1) at 180°C for 40 seconds;

[0028] 3) Spray the large circle façade 3 of the automobile brake disc and the small circle façade 1 of the automobile brake disc in step 2) with Dacromet paint, the friction surface 2 of the automobile brake disc and the mating surface 4 of the automobile brake disc and the rim No spraying, then pre-bake at 190°C for 6 minutes;

[0029] 4) The automobile brake disc in step 3) was sintered and solidified at 390°C for 32 minutes, and then cooled naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com