Preparation method of oil-in-water self-emulsifying agent

A self-emulsifier, oil-in-water technology, used in chemical instruments and methods, transportation and packaging, chemical/physical processes, etc., can solve problems such as poor product stability, limited emulsification range, and delamination, and achieve strong stability. , good spreading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

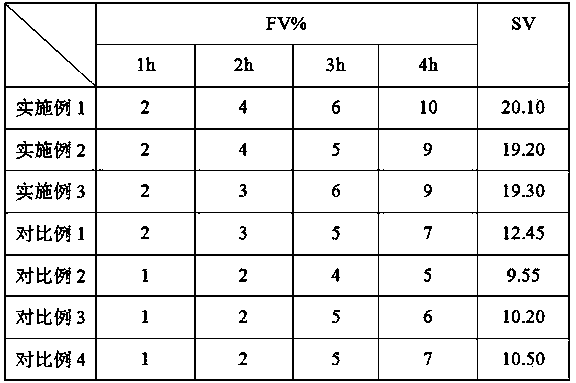

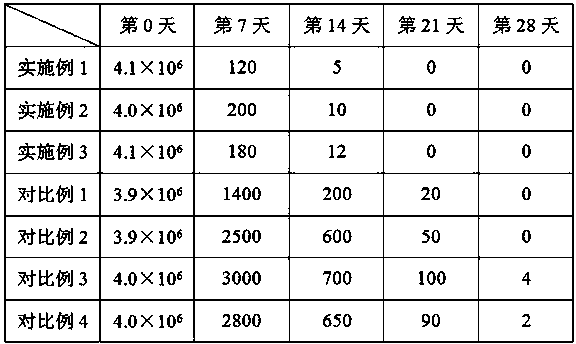

Examples

Embodiment 1

[0020] A preparation method of oil-in-water self-emulsifier, comprising the steps of:

[0021] (1) Add 3 parts of stearic acid and 0.2 parts of molecular sieve to 9 parts of glycerin, heat to 70°C, undergo esterification reaction to obtain crude glycerol stearate, spray dry the crude product to obtain glyceryl stearate;

[0022] (2) React 8 parts of stearic acid, 10 parts of polyethylene glycol and 0.3 parts of nickel at 120°C for 3 hours to generate PEG-100 stearate crude product through esterification reaction, dehydrate the crude product, and spray dry it. Obtain PEG-100 stearate;

[0023] (3) Add 3 parts of glycerol stearate and 7 parts of PEG-100 stearate into the reaction kettle, heat to 90°C, stir for 50 minutes, add 9 parts of ethanol, mix well, concentrate under reduced pressure again, and steam out ethanol, filtered, and dried to obtain the oil-in-water self-emulsifier.

Embodiment 2

[0025] A preparation method of oil-in-water self-emulsifier, comprising the steps of:

[0026] (1) Add 4 parts of stearic acid and 0.1 part of molecular sieve to 6 parts of glycerin, heat to 80°C, undergo esterification reaction to obtain crude glycerol stearate, spray dry the crude product to obtain glyceryl stearate;

[0027] (2) React 6 parts of stearic acid, 12 parts of polyethylene glycol and 0.2 parts of nickel at 140°C for 2 hours, esterification reaction occurs to generate PEG-100 stearate crude product, dehydrate the crude product, spray dry, Obtain PEG-100 stearate;

[0028] (3) Add 4 parts of glycerol stearate and 6 parts of PEG-100 stearate into the reaction kettle, heat to 100°C, stir for 40 minutes, add 10 parts of ethanol, mix well, concentrate under reduced pressure again, and steam out ethanol, filtered, and dried to obtain the oil-in-water self-emulsifier.

Embodiment 3

[0030] A preparation method of oil-in-water self-emulsifier, comprising the steps of:

[0031] (1) Add 2 parts of stearic acid and 0.3 parts of molecular sieve to 12 parts of glycerin, heat to 60°C, undergo esterification reaction to obtain crude glycerol stearate, spray dry the crude product to obtain glyceryl stearate;

[0032] (2) React 10 parts of stearic acid, 8 parts of polyethylene glycol and 0.4 parts of nickel at 100°C for 4 hours to generate PEG-100 stearate crude product through esterification reaction, dehydrate the crude product, and spray dry it. Obtain PEG-100 stearate;

[0033] (3) Add 2 parts of glycerol stearate and 8 parts of PEG-100 stearate into the reaction kettle, heat to 80°C, stir for 60 minutes, add 8 parts of ethanol, mix well, concentrate again under reduced pressure, and steam out ethanol, filtered, and dried to obtain the oil-in-water self-emulsifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com