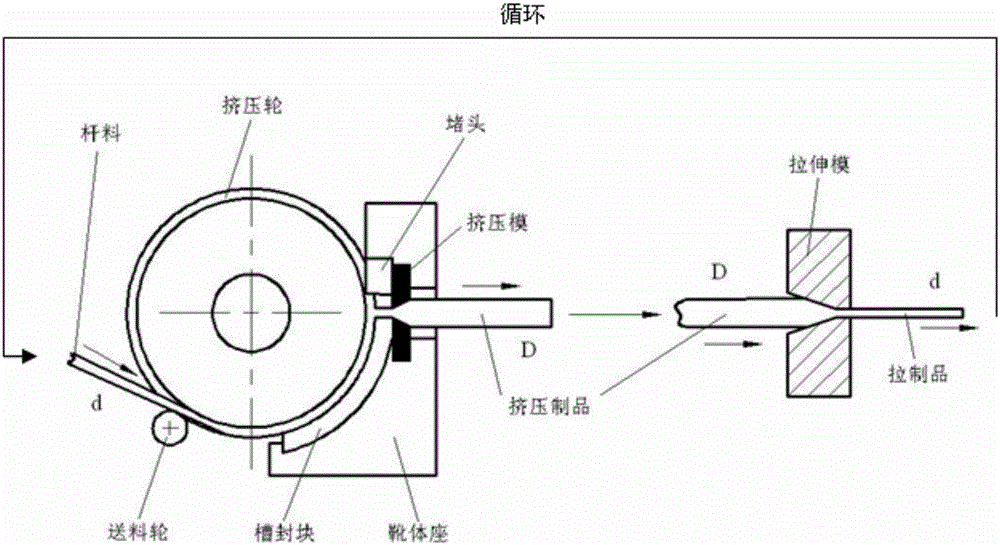

Continuous SPD (severe plastic deformation) method, used equipment and application of method

A large plastic deformation and equipment technology, applied in the field of plastic processing and forming, to achieve the effect of uniform product structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

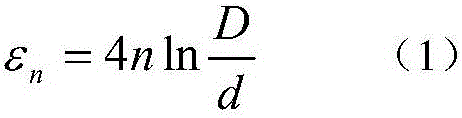

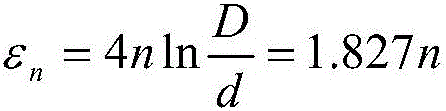

Method used

Image

Examples

Embodiment 1

[0038] First, the continuous casting and rolling 1050 aluminum alloy disc rod material with a diameter of d = 9.5mm is continuously extruded into an extruded product with a diameter of D = 15mm by using the expansion die technology, the extrusion wheel speed is 22rpm, and the extrusion outlet temperature The temperature is 460°C, and the die outlet is 1500mm into the water tank for cooling, drying, and winding; then, the extruded product with a diameter of D = 15mm is drawn into a wire rod with a diameter of d = 9.5mm after 8 passes; The surface of the drawn wire rod with a diameter of d=9.5mm is cleaned, rinsed and dried, and then continuously extruded under the same conditions into an extruded product with a diameter of D=15mm by using the expanding die technology. After 4 cycles like this, the tensile mechanical properties of the 1050 aluminum alloy after continuous extrusion and drawing of each pass were measured respectively. The results are shown in Table 1. It can be see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com