Integrated welding shooting structure and device and method for detecting automatic welding of cell

A battery cell and image capture technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of large installation space and complex structure, and achieve the effects of simplifying the structure, saving space resources, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

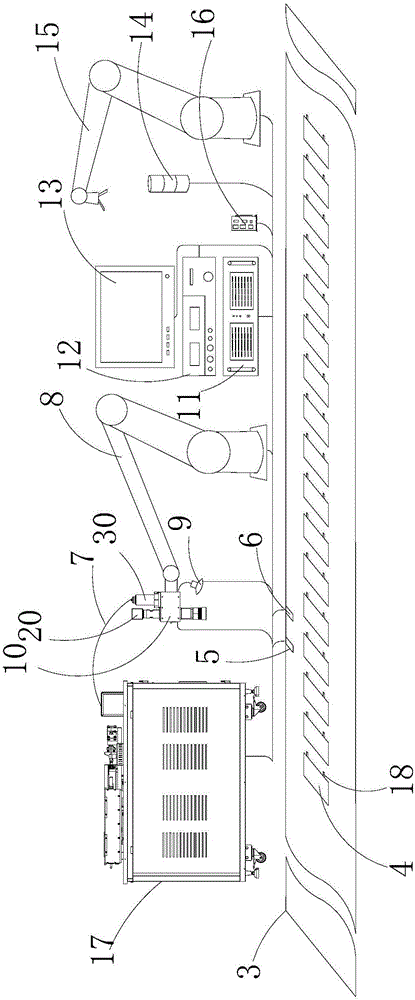

[0052] Such as Figure 1~4 In the specific embodiment shown, the integrated welding shooting structure provided by this embodiment can be used in the laser welding process of the tab 18 of the battery, or can be used in the laser welding process of other workpieces, so as to realize timely Take photos for inspection, improve inspection and production efficiency, do not need to occupy more space resources, and improve the stability of inspection quality while reducing inspection costs.

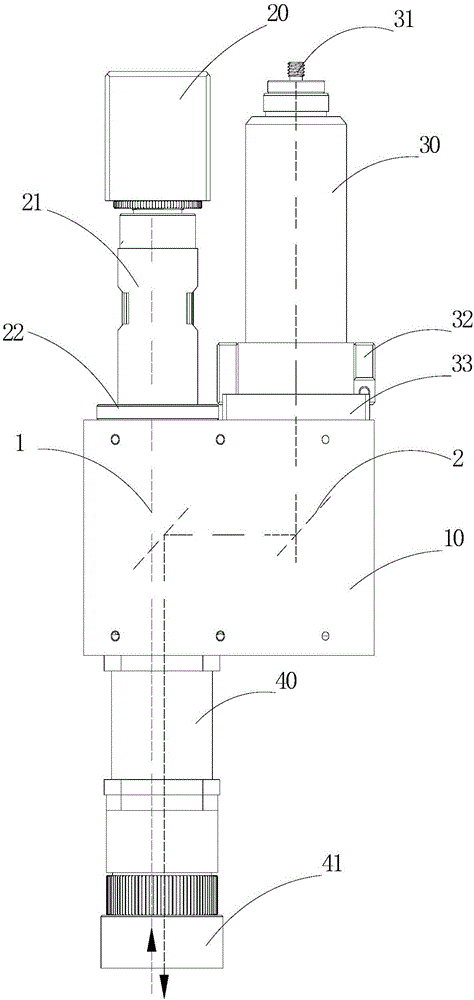

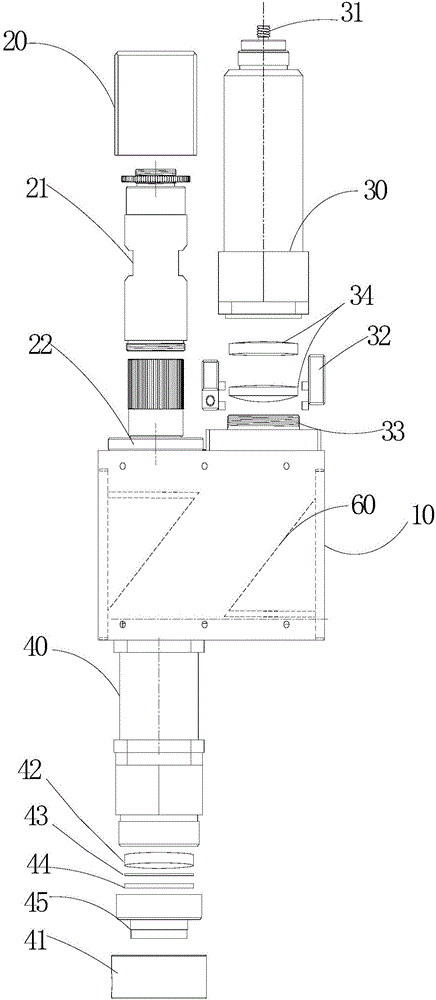

[0053] By sharing the optical path of the illumination light and the laser, the two different functional devices of laser welding and image shooting are combined into one, which includes a base 10, a photographing component, a laser input optical path c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap