An AC Electromagnetically Driven Abrasive Slurry Jet Supercharging Device

An abrasive slurry jet and electromagnetic drive technology, which is applied in the direction of abrasive feeding device, used abrasive processing device, abrasive, etc., can solve the problem that the positive arc-shaped platinum-plated electrode plate and the negative arc-shaped platinum-plated electrode cannot be guaranteed. Plate electric field strength and electric field uniformity, the electrode density of the electrode plate cannot be increased, and the energy loss cannot be sufficiently reduced to achieve the effects of simple structure, reduced energy loss, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations.

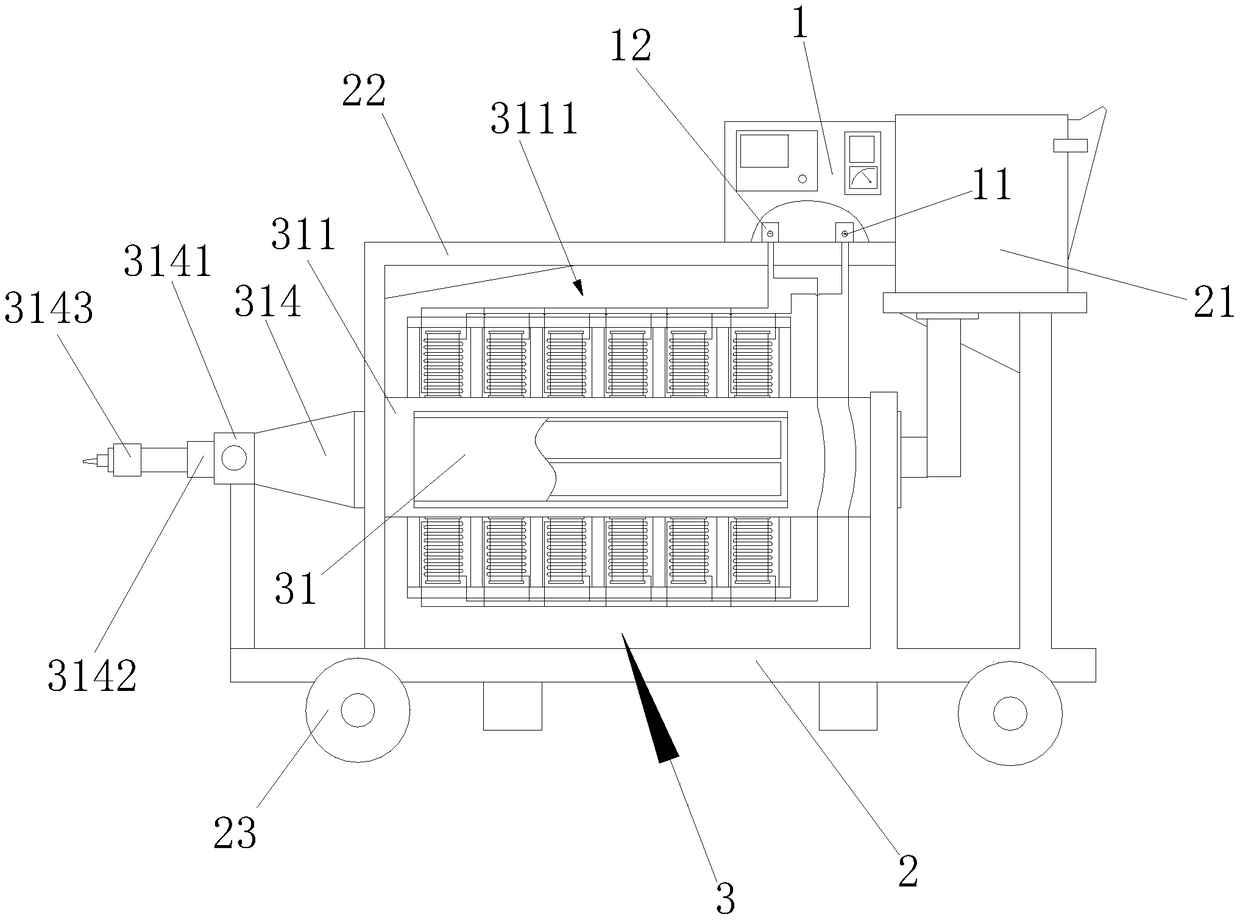

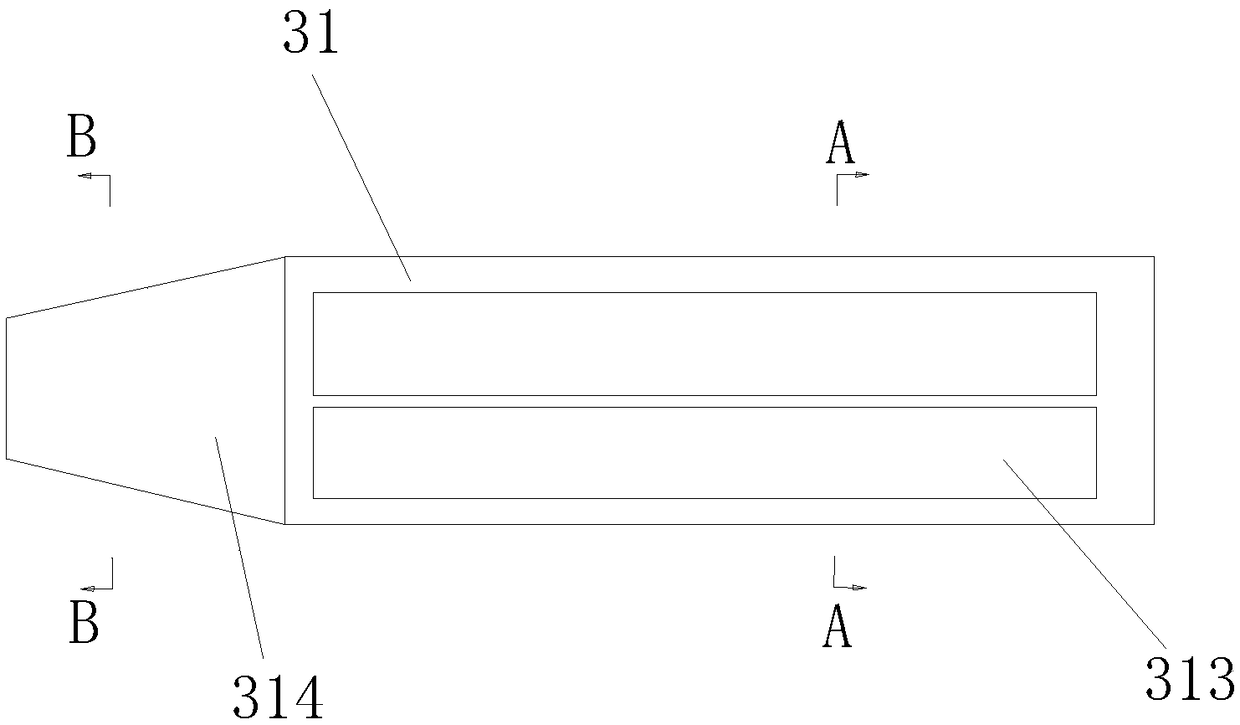

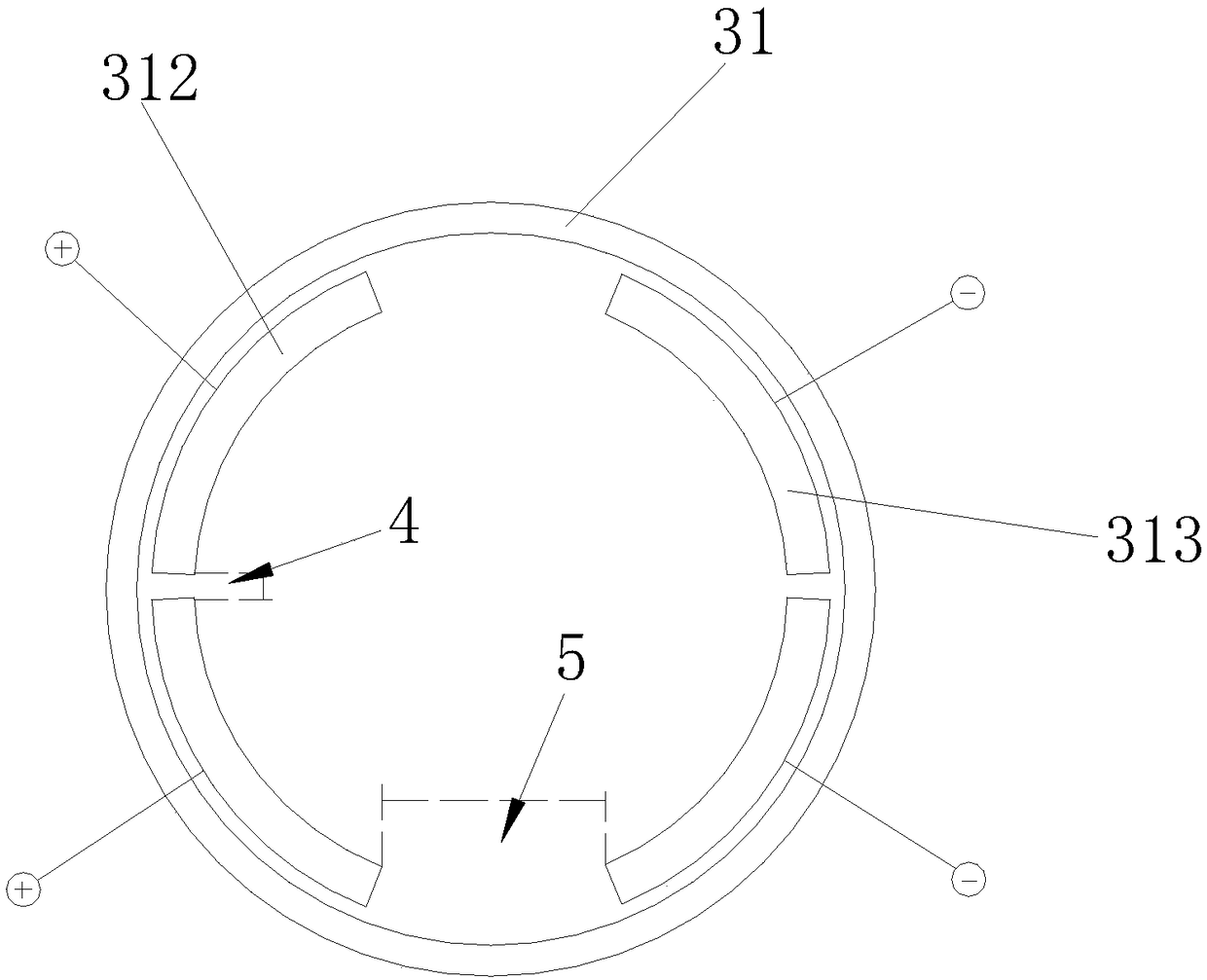

[0020] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the ac type electromagnetically driven abrasive slurry jet supercharging device includes an ac control box 1 and a moving frame 2, the lower end of the ac control box 1 is equipped with a positive terminal block 11 and a negative terminal block 12, and Comprising an orthogonal electromagnetic field driving device 3, the orthogonal electromagnetic field driving device 3 includes a circular cross-section flow channel 31, a nylon square frame 311 is installed on the outside of the circular cross-section flow channel 31, and the upper side of the nylon square frame 311 and the underside of the nylon square frame 311 are equipped with a energized coil row 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com