Steel wire rope detecting and tensioning device for high-altitude vehicle

A technology of tensioning device and wire rope, which is applied in the direction of lifting device, safety device for lifting equipment, transportation and packaging, etc. , the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

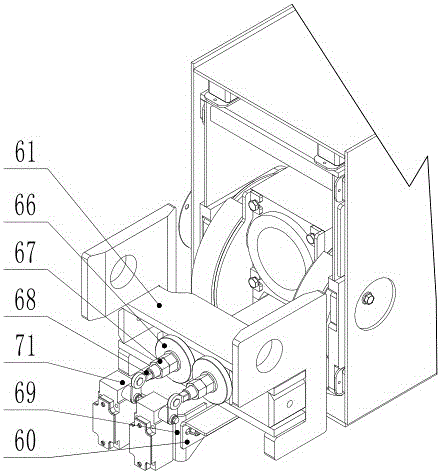

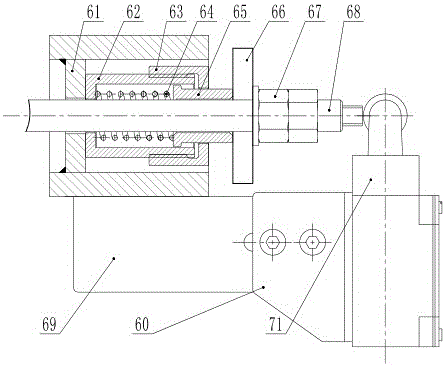

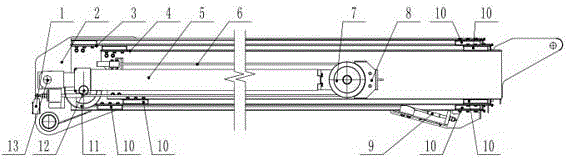

[0046] Example 1, such as figure 1 and figure 2As shown, a high-altitude vehicle steel wire rope detection tensioning device includes a vehicle arm, a steel wire rope 68 for pulling the vehicle arm and a tension adjustment device 1 for adjusting the steel wire rope 68, and the steel wire rope 68 includes a threaded connection. The tension adjusting device 1 includes a crossbeam 61, a spring 64 against the crossbeam 61, a locking nut 67 connected to the threaded connection, and the spring can be approached and compressed under the push of the locking nut 67. The tensioning sleeve 65 of 64 also includes a travel switch 71 used in conjunction with the rope end of the steel wire rope 68 .

[0047] It also includes a large sleeve 62 and a large nut 63 that conflict with the beam 61, the spring 64 is located in the cavity formed by the large sleeve 62 and the large nut 63, and one end of the spring 64 is connected to the large nut 63. The sleeve 62 is in conflict, and the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com