Novel water purifying machine with pure-water-membrane-soaking function during stopping resting

A water purifier, pure water technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of scaling on the surface of RO diaphragm membrane, RO water purifier Problems such as high TDS value of initial water production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

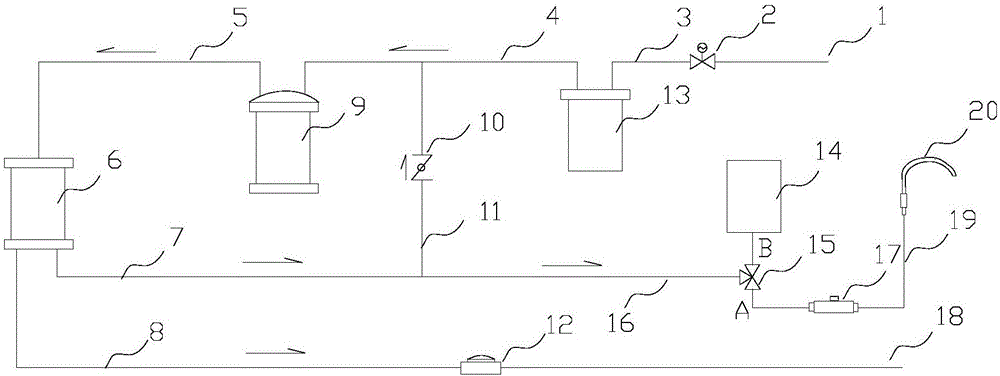

[0012] see figure 1 Shown, the present invention will be further described in conjunction with the following examples,

[0013] A new type of water purifier with the function of pure water bubble film when it is stopped and still, including a water inlet electric valve 2, a filter element mechanism 13, a booster pump 9, an RO membrane group 6 connected in sequence through pipelines, and a check valve 10 , one-inlet and two-outlet electric valve 15, pure water storage tank 14, pure water faucet high-pressure switch 17, pure water faucet 20, micro-wastewater ratio combination solenoid valve 12; water inlet electric valve 2 is connected with raw water (tap water) pipeline 1, water inlet electric The water outlet of the valve 2 is connected to the water inlet of the filter element mechanism 13 through the pipeline 3, the water outlet of the filter element mechanism 13 is connected to the water inlet of the booster pump 9 through the pipeline 4, and the water outlet of the booster ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com