Steel slag powder-doped concrete and preparation method thereof

A technology of steel slag powder and concrete, which is applied in the field of building materials, can solve the problems of high flexural strength, achieve high flexural strength, improve flexural and compressive strength, and have good activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

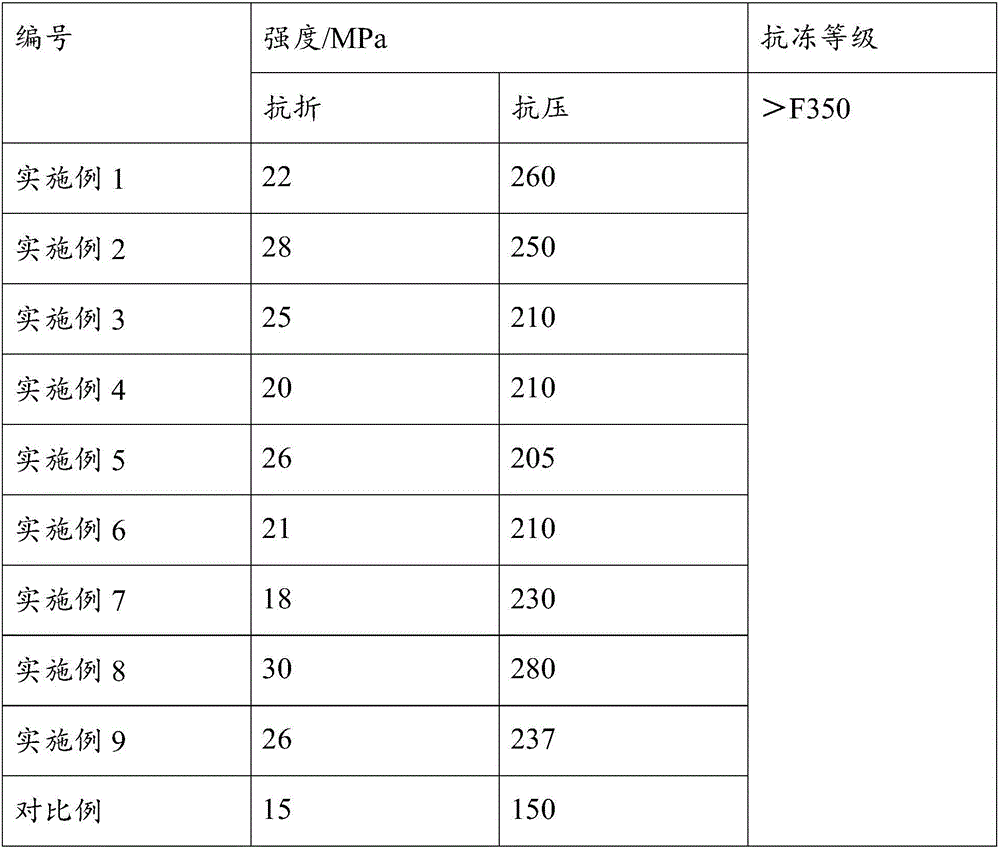

Examples

Embodiment 1

[0042] The concrete mixed with steel slag powder provided by this application specifically includes the following components:

[0043] Aluminate cement 40kg, steel slag powder 20kg, quartz sand 90kg, water 10kg and gravel 100kg.

[0044] The preparation method of the concrete mixed with steel slag powder specifically comprises the following steps:

[0045] Add cement, steel slag powder, stones and quartz sand into the mixer in sequence for 2 to 3 minutes and dry mix for 2 to 3 minutes, pour water and continue stirring until slurry appears to obtain the concrete mixed with steel slag powder.

Embodiment 2

[0047] The concrete mixed with steel slag powder provided by this application specifically includes the following components:

[0048] P.O 32.5 60kg, specific surface area is 450m 2 / kg steel slag powder 40kg, quartz sand 110kg, water 20kg, stones with a particle size of 5mm 100kg and stones with a particle size of 20mm 100kg.

[0049] The preparation method of the concrete mixed with steel slag powder is the same as that in Example 1.

Embodiment 3

[0051] P.O 42.5 45kg, specific surface area 500m 2 / kg steel slag powder 25kg, quartz sand 95kg, water 11kg, stones with a particle size of 10mm 50kg and stones with a particle size of 20-40mm 50kg.

[0052] The preparation method of the concrete mixed with steel slag powder is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com