A method for improving biodiesel yield and reducing ester content in residual oil

A technology for biodiesel and residual oil, applied in the distillation control/regulation of hydrocarbon oil, etc., can solve the problems of increasing the acid value of biodiesel, reducing the yield of biodiesel, cracking of biodiesel, etc., so as to increase the volatility and reduce the Ester content, the effect of reducing the volatilization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

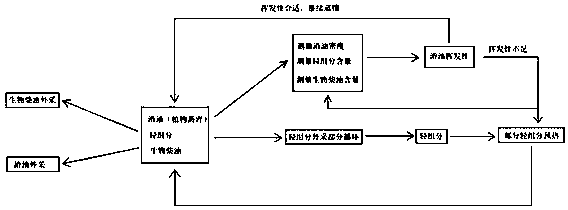

Image

Examples

Embodiment 1

[0023] A method for improving biodiesel yield and reducing ester content in residual oil, comprising the steps of:

[0024] (1) Distillation produces residual oil, light components, and biodiesel fractions;

[0025] (2) Real-time measurement of residual oil density, real-time measurement of light component content, and real-time measurement of biodiesel content;

[0026] (3) Judging that the content of light components reaches the specified value, that is, the content of undecyl carbon is less than 0.5%, then the light components are collected outside; if the content, density, acid value, sulfated ash, and chroma of biodiesel esters are determined to reach the national standard, then Biodiesel mining;

[0027] (4) Determine the density of residual oil to determine whether the volatility is appropriate:

[0028] A. If the density and volatility of the residual oil are suitable, continue to distill and repeat steps (1), (2) and (3);

[0029] B. If the density of the residua...

Embodiment 2

[0036] A method for improving biodiesel yield and reducing ester content in residual oil, comprising the steps of:

[0037] (1) Distillation produces residual oil, light components, and biodiesel fractions;

[0038] (2) Real-time measurement of residual oil density, real-time measurement of light component content, and real-time measurement of biodiesel content;

[0039] (3) Judging that the content of light components reaches the specified value, that is, the content of undecyl carbon is less than 0.5%, then the light components are collected outside; if the content, density, acid value, sulfated ash, and chroma of biodiesel esters are determined to reach the national standard, then Biodiesel mining;

[0040] (4) Determine the density of residual oil to determine whether the volatility is appropriate:

[0041] A. If the density and volatility of the residual oil are suitable, continue to distill and repeat steps (1), (2) and (3);

[0042] B. If the density of the residua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com