A kind of preparation method of oxidized microcrystalline wax

A technology for oxidizing microcrystalline wax and microcrystalline wax, which is applied in the refining of petroleum wax, etc., can solve the problems of unsatisfactory catalyst regeneration effect, low chemical reaction activity, unsuitable microcrystalline wax oxidation, etc., so as to improve catalyst selectivity and operation. Simple and flexible, the effect of improving the yield of the target product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

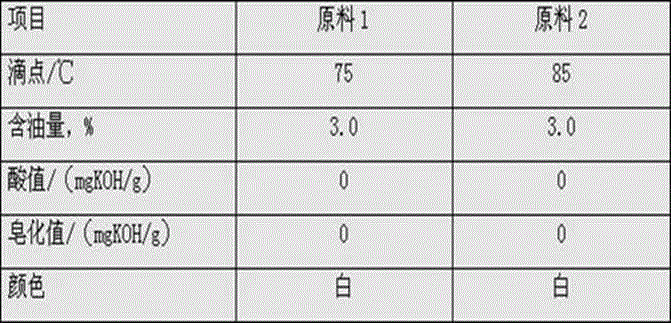

Embodiment 1

[0021] This embodiment adopts raw material 1, and the HCl aqueous solution that contains 70mL / L in the air used, specific reaction condition and product property are shown in Table 2.

Embodiment 2

[0023] Using raw material 2, the HCl aqueous solution containing 90mL / L in the air used, the specific reaction conditions and product properties are shown in Table 2.

Embodiment 3

[0025] Same as Example 1, the air used contains 70mL / L of HCl aqueous solution, the difference is that the reaction conditions are different, and the specific reaction conditions are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com