Plate-pipe connecting method and device based on local radial extrusion

A local radial, pipe connection technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of difficult welding, non-compliance with lightweight design requirements, environmental pollution, etc., to achieve the effect of flexible connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and a specific embodiment, which is an explanation of the present invention rather than a limitation.

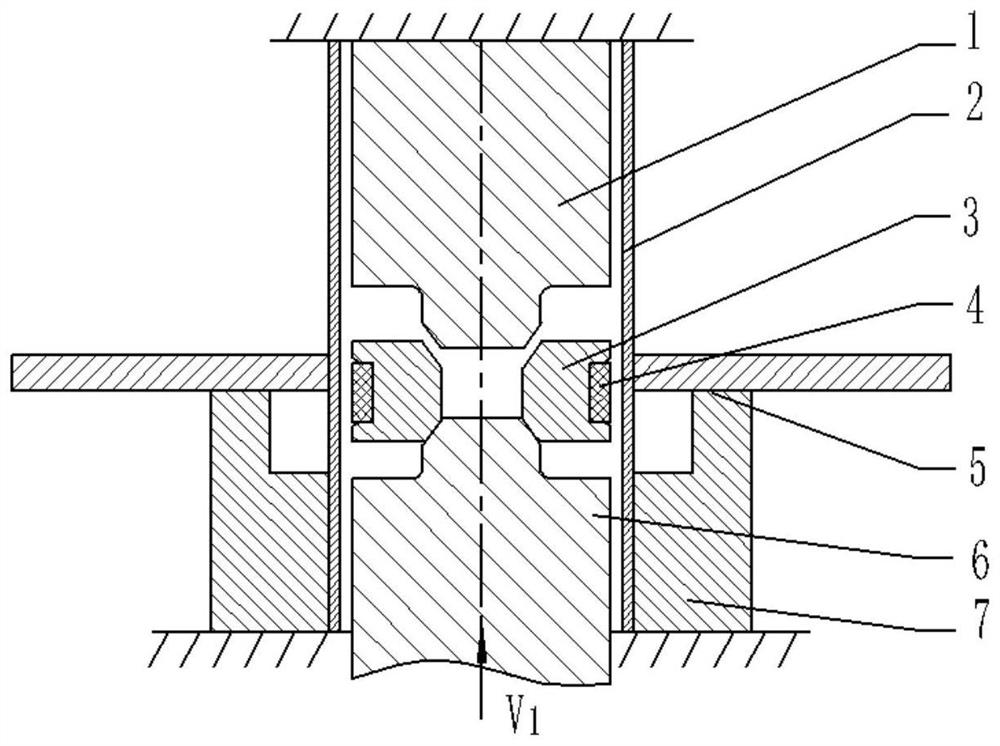

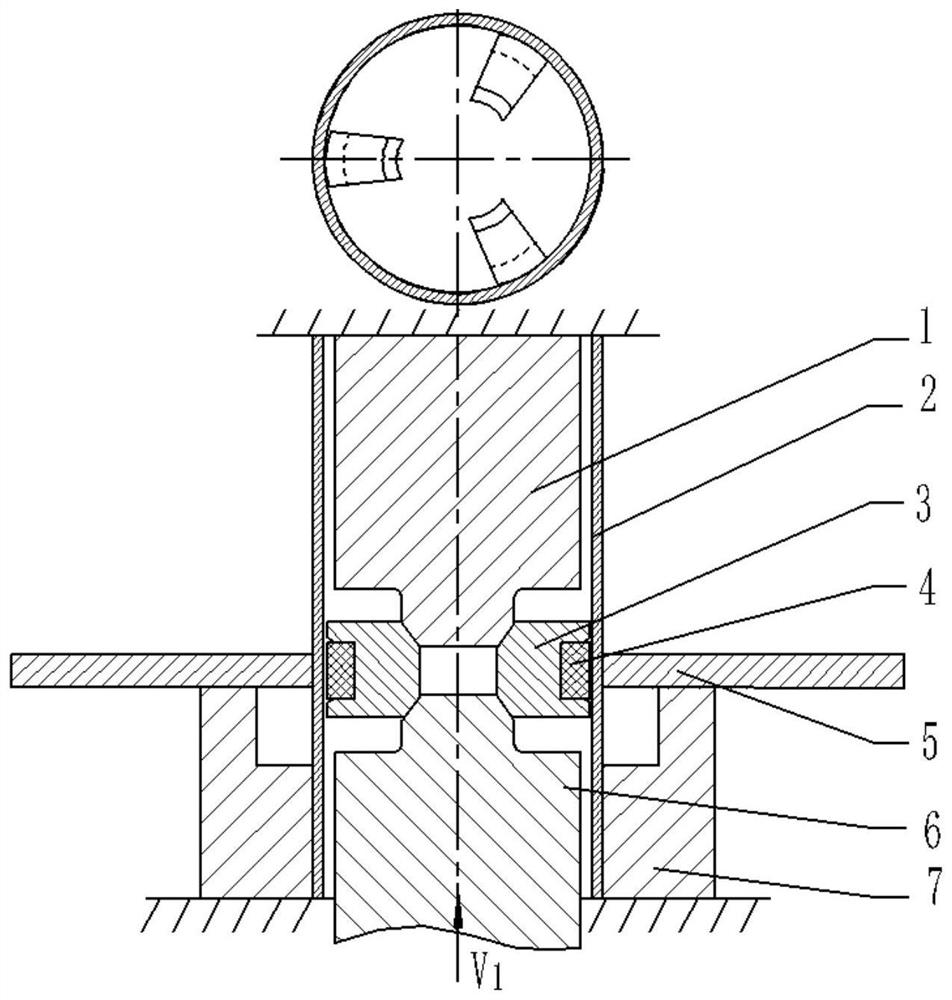

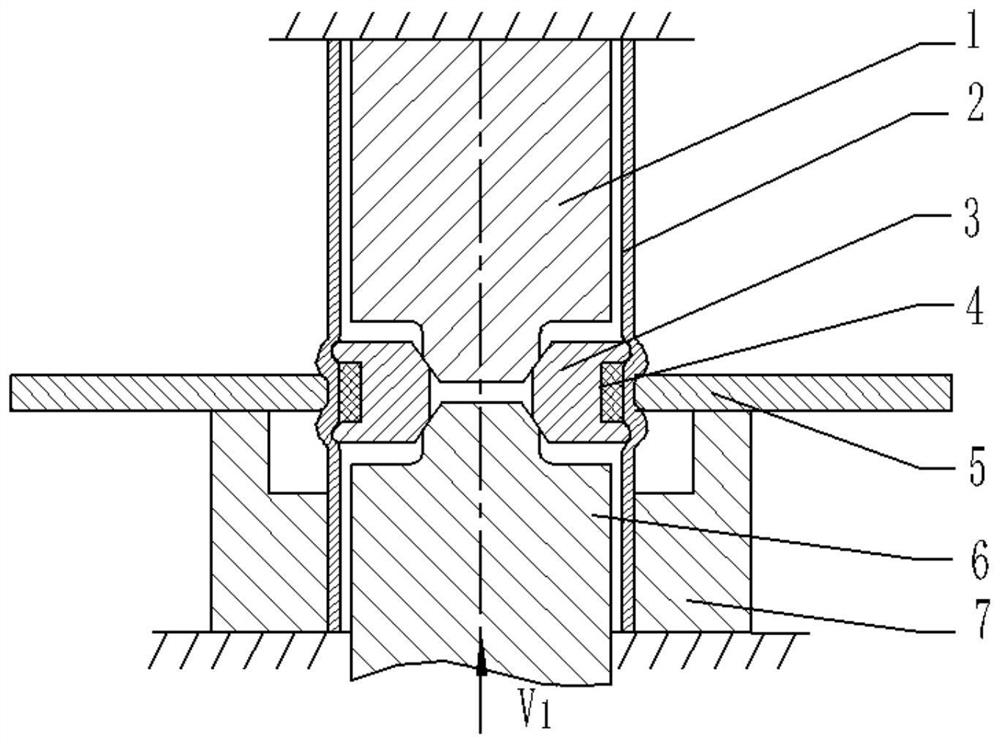

[0037] Such as figure 1 , in order to realize a set of specific devices of the present invention, take this as an example to specifically explain the plate-pipe connection method based on local radial extrusion of the present invention, which does not constitute a limitation of the present invention. The method of the present invention can utilize any The existing device of its step-by-step function realizes.

[0038]The device comprises an upper die 1, an extrusion die 3, an elastic body 4, a lower die 6 and a support die 7, and is characterized in that the lower end of the upper die 1 and the upper end of the lower die 6 are convex extrusion parts, and the extrusion die 3. The shape of the inner upper part matches the lower end of the upper die 1, and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com