Aqueous nanometer inorganic oxide-organic hybrid coating composition and its application

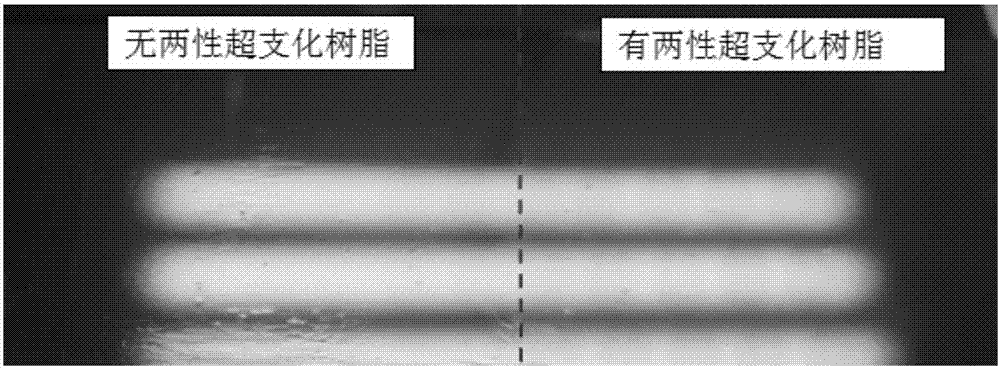

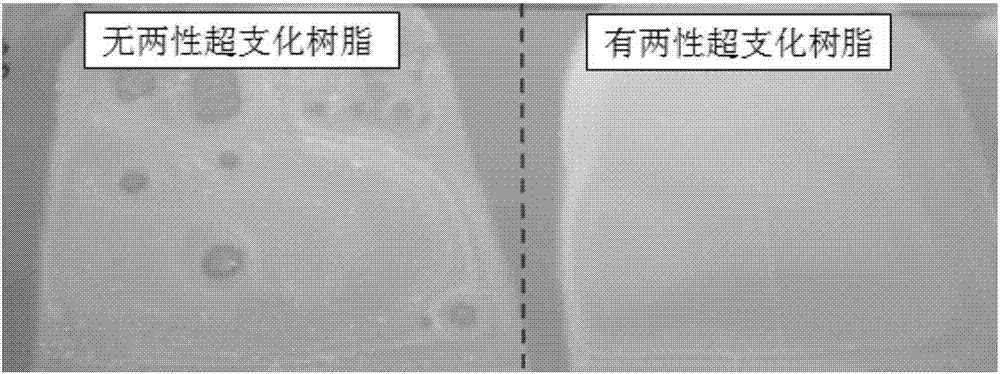

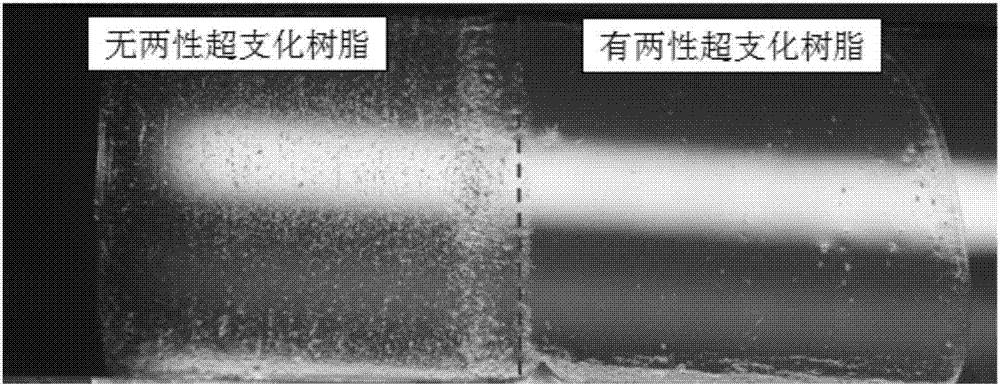

A nano-inorganic and organic hybrid technology, applied in the field of coatings, to achieve the effect of improving stain resistance, increasing hydrophilicity, and changing the surface morphology of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0080] Example 1. Synthesis of amphoteric hyperbranched resin AMP1

[0081] 1A. Synthesis of Intermediate 1A

[0082] Under the protection of dry nitrogen, stir and heat H20 solid (100 parts) and DMM (50 parts) to 110-120 degrees for about 10-20 minutes. After forming an emulsion, add Capa (50 parts), and the resulting solution is heated to 130-140 degrees, heat preservation and stirring for about 1 hour until Capa is completely consumed (monitored by GC).

[0083] 1B. Synthesis of Hybrid Prepolymer 1B

[0084] Under dry air atmosphere and room temperature conditions, IPDI (1000.0 parts), DMM (866.9 parts), iron acetylacetonate (0.064 parts) and BHT (1.88 parts) were mixed and stirred uniformly. With full stirring, PFHE (525.9 parts), HEMA (230.0 parts) and MPEG750 solution (dissolved in DMM, 80% mass concentration, 1656.8 parts) were added slowly in sequence for about 30 minutes respectively. Finally, the temperature was raised to 40° C., the temperature was kept and the sti...

example 2

[0088] Example 2. Synthesis of amphoteric hyperbranched resin AMP2

[0089] 2A. Synthesis of Hybrid Prepolymer 2A

[0090] Under dry nitrogen atmosphere and room temperature conditions, with full stirring, EHA (33.14 parts), 80% by mass percentage MPEG750 DMM solution (132.50 parts) was added slowly in turn to IPDI (80.00 parts), DMM (56.00 parts) and iron acetylacetonate (0.009 parts) of the mixture, after about 60 minutes after the addition, the temperature was raised to 40° C. and the reaction was stirred for about 3 hours until the NCO% reached the theoretical value of 4.51%.

[0091] 2B. Synthesis of amphoteric hyperbranched polymer AMP2

[0092] Under a dry nitrogen atmosphere, the intermediate 1A (105.00 parts) prepared according to the example 1A was stirred and heated to about 70 degrees, and then the mixed prepolymer 2A (274.60 parts) prepared according to the example 2A and the catalyst K-KAT348 (0.14 parts ) stirring and adding, heating up to 80-90°C, insulated a...

example 3

[0094] Example 3. Synthesis of Amphoteric Hyperbranched Resin AMP3

[0095] 3A. Synthesis of Prepolymer 3A

[0096] Under dry nitrogen atmosphere and room temperature conditions, with sufficient stirring, the DMM solution (350.70 parts) of 80% by mass percentage MPEG750 is slowly added in the mixture of IPDI (75.60 parts), DMM (48.40 parts) and iron acetylacetonate (0.016 parts) , after about 45 minutes of addition, the temperature was raised to 40°C and the reaction was stirred for about 3 hours until the NCO% reached the theoretical value of 2.71%.

[0097] 3B. Synthesis of Intermediate 3B

[0098] Under a dry nitrogen atmosphere, the intermediate 1A (280.00 parts) prepared according to Example 1A was stirred and heated to about 70 degrees, and then the prepolymer 3A (435.40 parts) prepared according to Example 3A and catalyst K-KAT348 (0.075 parts) Stir and add, heat up to 80-90 degrees, keep warm and stir for about 3 hours, then cool down to room temperature and ripen fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com