460MPa-grade high-toughness low-alloy high-strength structural steel plate and production method thereof

A low-alloy high-strength, high-strength production method technology, applied in the field of low-alloy high-strength structural steel plate production technology, can solve the problems of long production cycle, high energy consumption, and increased costs, and achieve excellent low-temperature impact toughness, simple chemical composition, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

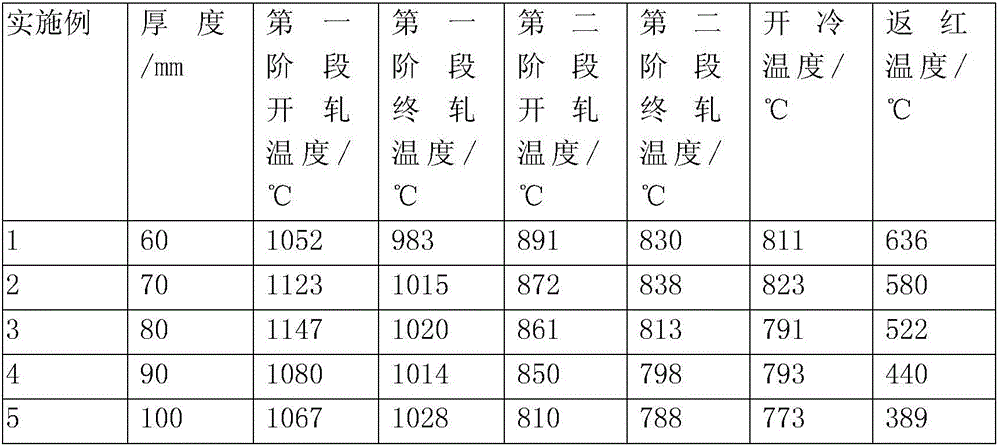

[0027] The 460MPa level high-toughness low-alloy high-strength structural steel of the present invention and its production method are further described below by specific examples:

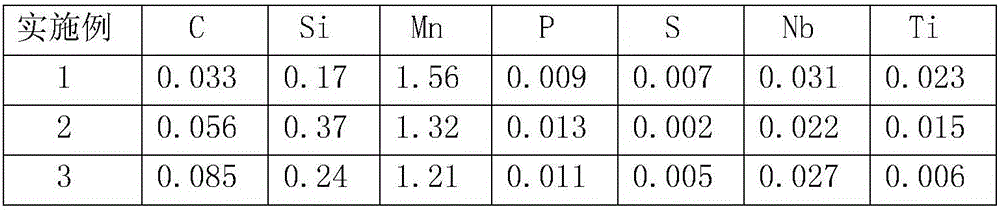

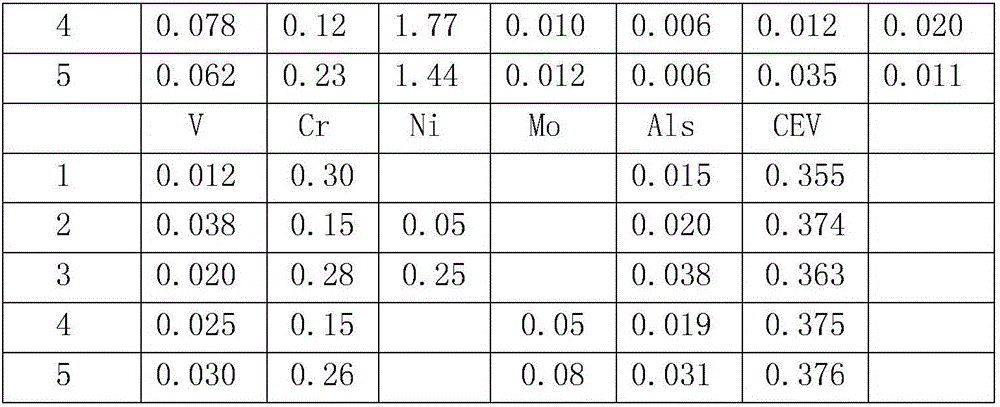

[0028] Table 1 has listed the percentage by weight of the chemical composition of the 460MPa level high toughness low alloy high strength structural steel of embodiment 1-5 (surplus is Fe and unavoidable impurity)

[0029] Table 1 embodiment 1-5 chemical composition (w%)

[0030]

[0031]

[0032] The steel in the above embodiments 1-5 is produced according to the following steps: smelting, refining, continuous casting, billet heating, controlled rolling, controlled cooling, slow cooling, and finished product.

[0033] When the steel billet is heated, the heating temperature is 1050-1220°C;

[0034] During controlled rolling, two-stage controlled rolling is adopted to fully refine the structure before phase transformation. The first-stage rolling temperature is 1030-1150°C, and the final ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com