Three-layer composite separation membrane support material

A supporting material and separation membrane technology, which is applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of easy leakage of glue through the bottom, low strength of separation membrane support body, and poor interlayer force, so as to solve the problems of easy leakage, Effects of improving physical and mechanical properties and structural stability, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

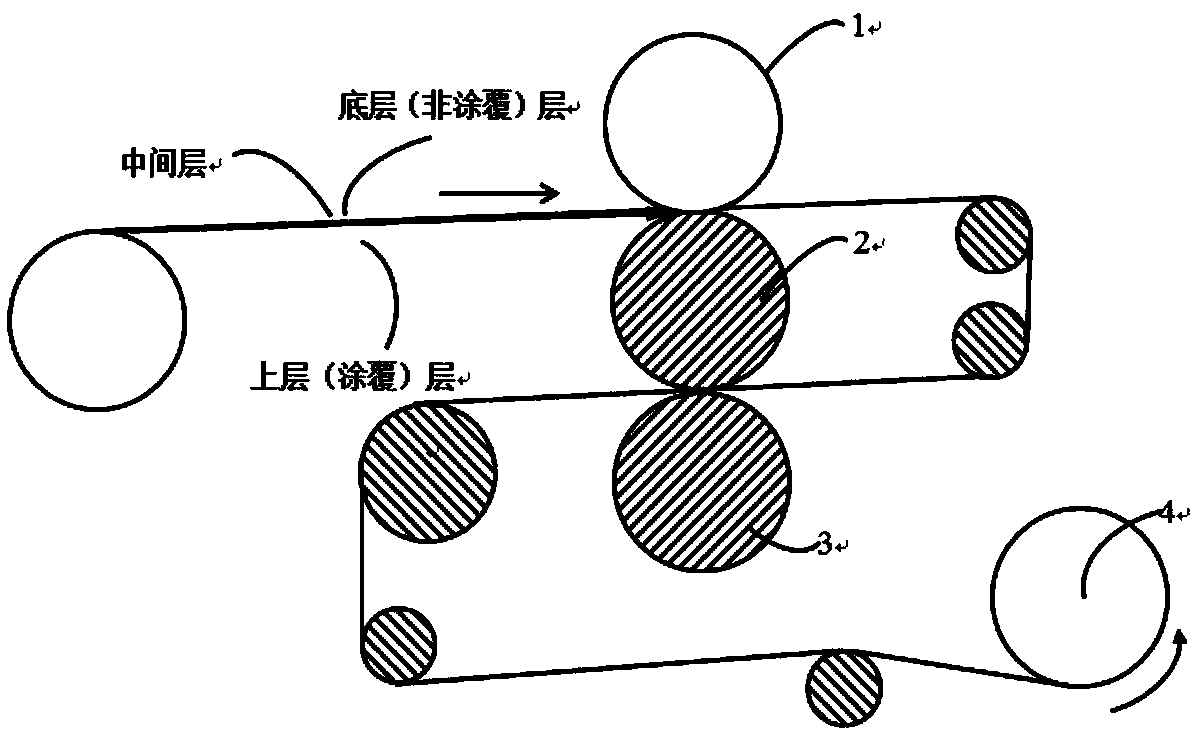

[0032] The preparation of the three-layer wet spunlace separation membrane support mainly includes the following steps:

[0033] 1. Wet process and spinning

[0034] Disperse polyester fiber (fiber diameter 6.3 μm, fiber length 5 mm) and ES fiber (3.2 μm, fiber length 5 mm) in water at a mixing ratio of 60:40, control the fiber concentration to 2%, defrost for 40 minutes, and put it into the slurry pool, add water and polyacrylamide dispersant and stir evenly to make the concentration 0.03%, the viscosity is 60 seconds, make the upper layer (coating layer) slurry, and pass through the wet forming machine to obtain a dry weight of 20g / m 2 upper fiber web;

[0035]Disperse polyester fibers (fiber diameter 14.5 μm, fiber length 5 mm) and polyethylene fibers (10.2 μm, fiber length 5 mm) in water at a mixing ratio of 60:40, control the fiber concentration to 2%, defecate for 40 min, put into the In the slurry tank, add water and polyacrylamide dispersant and stir evenly, so that ...

Embodiment 2

[0042] The preparation of the three-layer wet spunlace separation membrane support mainly includes the following steps:

[0043] 1. Wet Laying and Spunlaid

[0044] Polyester fibers (fiber diameter 7.2 μm, fiber length 5 mm) and low-melting polyester fibers (melting point 130 ° C, 4.3 μm, fiber length 5 mm) were dispersed in water at a mixing ratio of 60:40, and the fiber concentration was controlled to be 2%. Decompose for 40 minutes, put it into the slurry mixing tank, add water and polyacrylamide dispersant, stir evenly, make the concentration 0.03%, and the viscosity is 60 seconds, make the upper layer (coating layer) slurry, and pass through the wet forming machine to obtain a dry weight of 20g / m 2 upper fiber web;

[0045] Disperse polyester fibers (fiber diameter 13.8 μm, fiber length 5 mm) and low-melting polyester fibers (melting point 130 ° C, 12.6 μm, fiber length 5 mm) in water at a mixing ratio of 60:40, and control the fiber concentration to 2%. Decompose for...

Embodiment 3

[0052] Using the same process conditions and processing methods as in Example 2, the different three-layer composite fiber webs were directly dried without spunlace, hot-rolled and calendered to obtain a quantitative 65.0g / m 2 The three-layer wet spunlace separation membrane support.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com