Lining trolley for construction of main cave and emergency vehicle avoidance strip and construction method of lining trolley

A technology for lining trolleys and construction trolleys, which is applied in wellbore linings, tunnel linings, earthwork drilling, etc., can solve the problems of long time-consuming, complicated process, and long reconstruction time, so as to improve work efficiency, simplify the assembly process, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

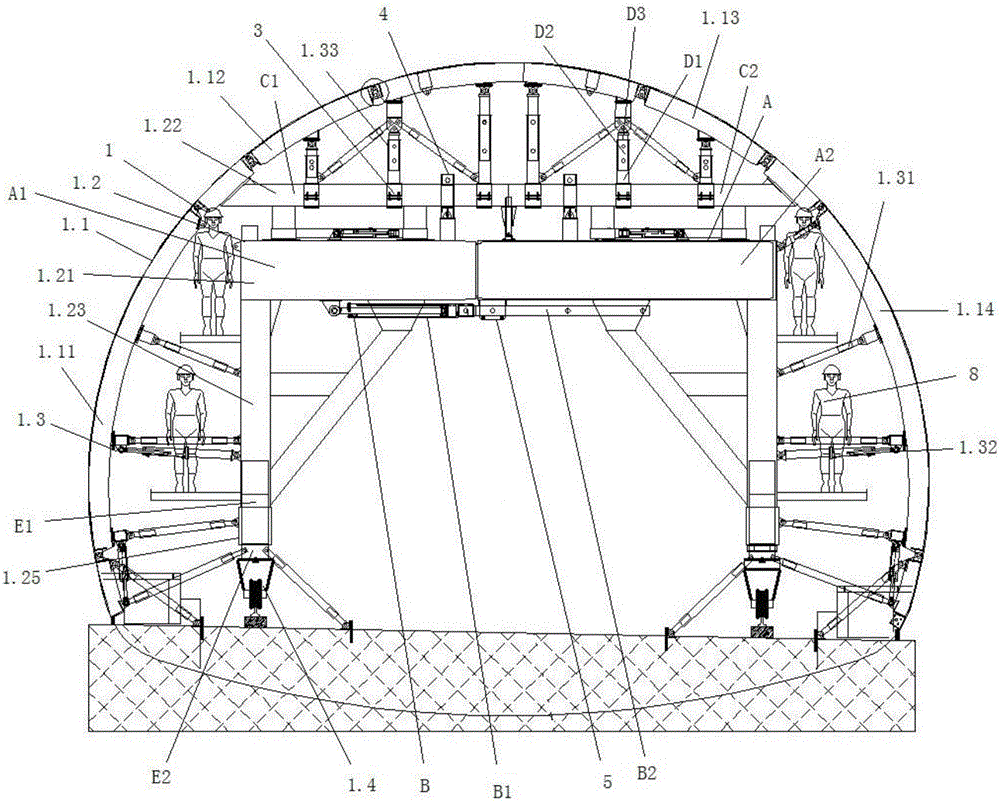

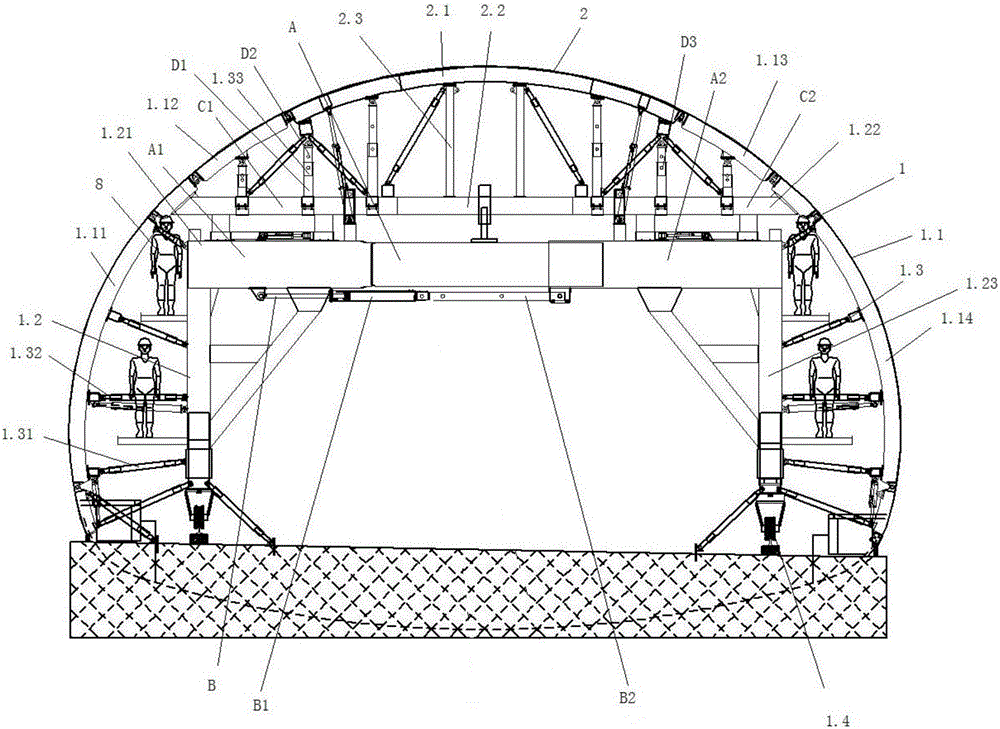

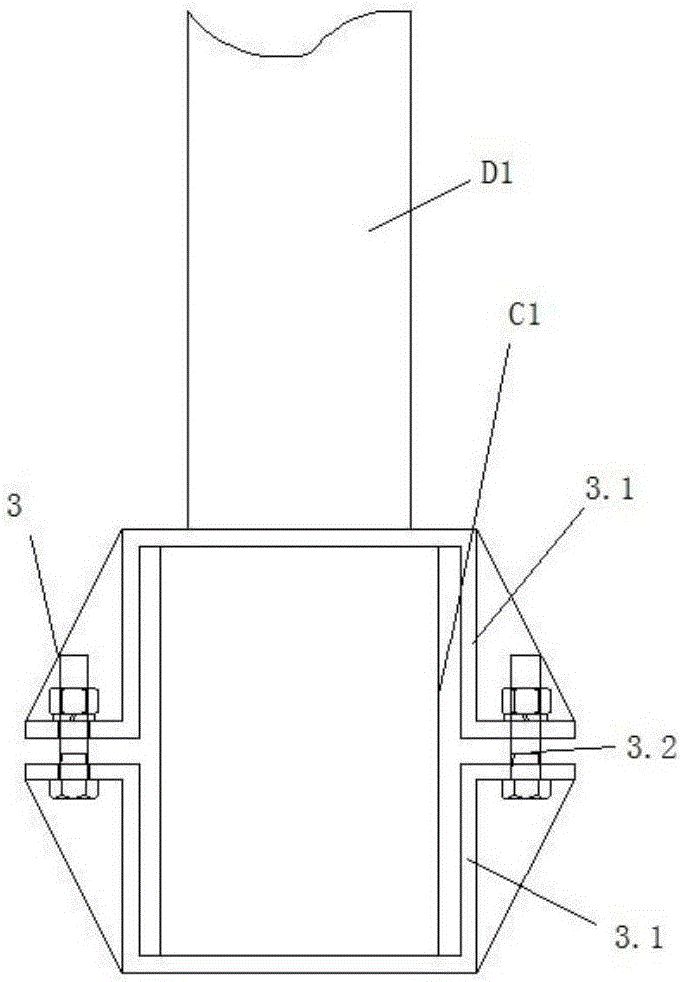

[0069] see Figure 1-Figure 8 , a lining trolley used for construction of a main cave and an emergency vehicle avoidance belt, comprising a trolley body, the trolley body includes a main cave construction trolley body 1 and a detachable type with the main cave construction trolley body 1 Attachment 2 for the construction of the connected emergency avoidance belt, see figure 2 .

[0070] The structure of the main hole construction trolley body 1 is detailed in figure 1 , specifically including a formwork part 1.1, a door frame part 1.2, a connecting part 1.3 connecting the formwork part 1.1 and the door frame part 1.2, and a running mechanism 1.4, the details are as follows:

[0071] The template part 1.1 includes a left template group 1.11, a left top template group 1.12, a right top template group 1.13, and a right template group 1.14 that are flexibly connected in sequence. Here, the left top template group 1.12 and the right top template group The formwork group 1.13 al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com