Great-pressure difference manual sealing slide plate gate

A sliding door and large pressure difference technology, which is applied in the direction of sliding valves, engine components, valve details, etc., can solve the hidden dangers of personal safety of operators, material or gas leakage, and affect the environment of the factory area, etc., so as to achieve good operation stability , low cost, good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

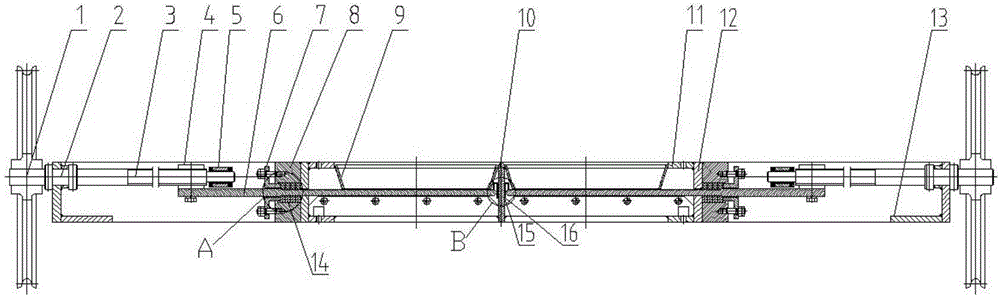

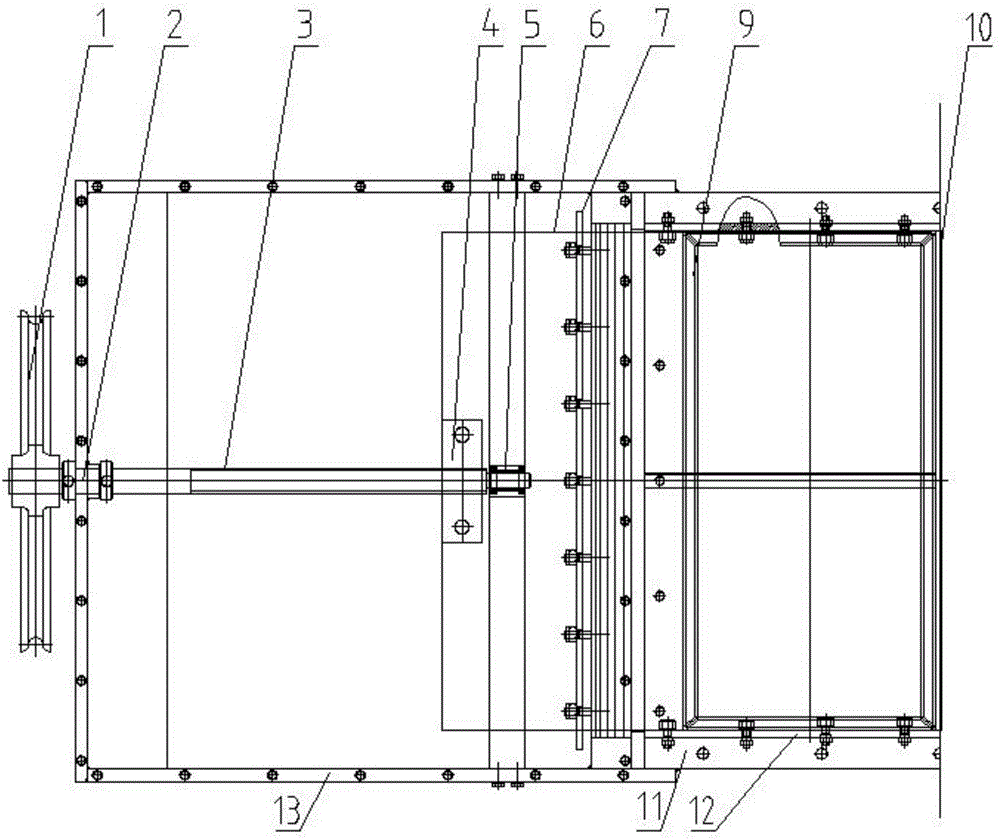

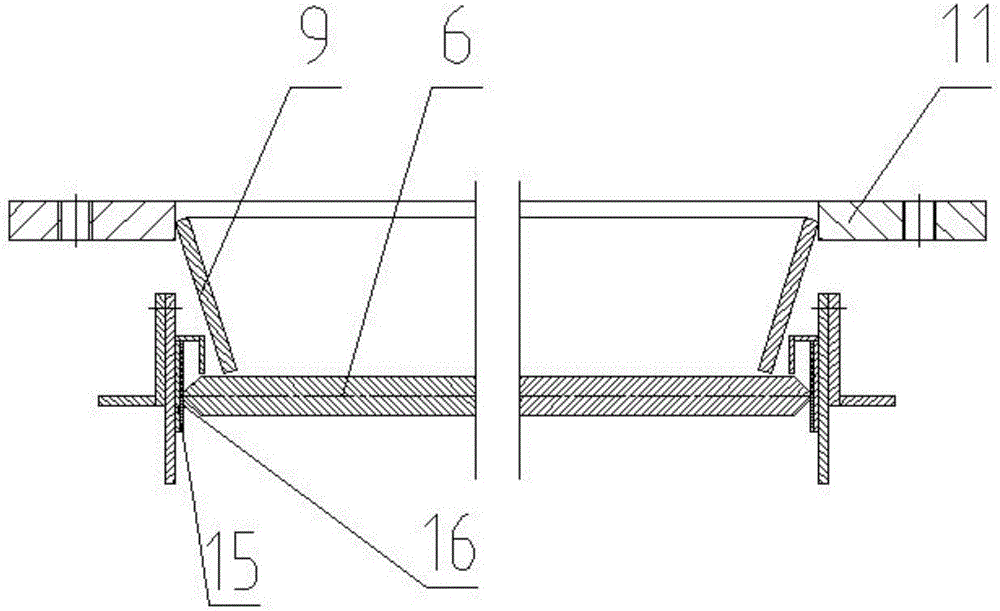

[0021] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , a large pressure difference manually sealed flapper door, comprising: a valve plate 6 with triangular sealing surfaces on three sides, a valve plate 6 with arc-shaped protrusions at the contact point with the sealing gasket 14 in the closed state, and a sealing ring 16 with a C-shaped structure; The three faces of the sealing ring 16 are respectively fixed on the front and rear inner walls of the valve plate seat 12 and the center partition 10 through the sealing ring fixing plate 15. The upper part of the sealing ring fixing plate 15 is provided with an L-shaped gray plate, and the sealing ring fixing plate 15 is arranged in the gap at the bottom of the tapered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com