Supersonic gas ejector

A technology of ejector and supersonic speed, which is applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problems that the long-term operation of wind tunnel equipment cannot be satisfied, the combustion parameters are difficult to adjust in real time, and cooling measures are difficult to adopt, and achieve Light weight, simple structure, and the effect of preventing air separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

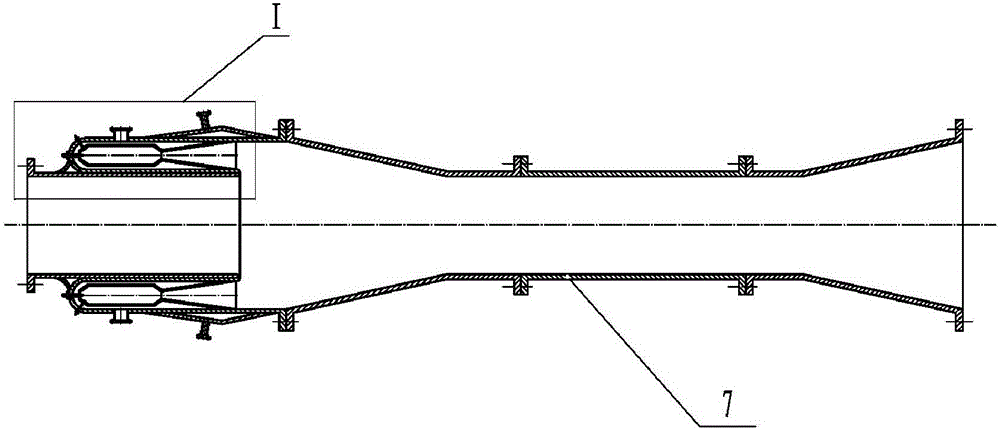

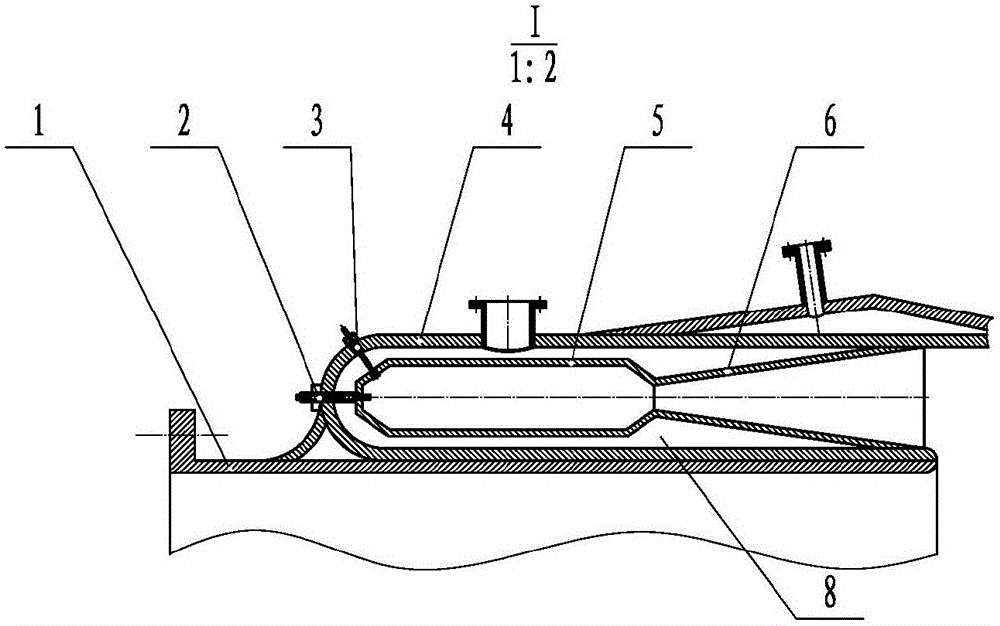

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0029] figure 1 It is a structural schematic diagram of the supersonic gas ejector of the present invention; Picture 1-1 yes figure 1 Zoom-in view of the middle I region. Such as figure 1 with Picture 1-1 As shown, the supersonic gas ejector includes: an air intake cylinder 1 , a fuel nozzle 2 , an igniter 3 , an ejector housing 4 , a combustion device and a diffuser device 7 . in,

[0030] The ejector housing 4 is sheathed on the outer surface of the intake tube 1 , and a cavity 8 is formed between the ejector housing 4 and the intake tube 1 . Specifically, the ejector housing 4 is sleeved on the outer surface of the air intake cylinder 1, an annular cavity 8 is formed between the ejector housing 4 and the air intake cylinder 1, and the axis of the ejector housing 4 is aligned with the air intake cylinder. The axes of 1 are the same axis.

[0031] The combu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com