Comprehensive judgment method of failure cause of reducer shaft of sluice gate of nuclear power equipment

A technology of reducer shafts and failure causes, which is applied in the field of comprehensive determination of failure causes of reducer shafts in nuclear power equipment water sluice gates, can solve problems such as inability to accurately analyze the causes of shaft failures, and achieve the effect of ensuring safe and stable development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1: The specific steps are as follows:

[0066] (1) Sorting and analysis of background data, sorting out and analyzing the background data of the nuclear power plant, the operating conditions of internal equipment, and the relevant technical parameters of the shaft of the sluice gate reducer, etc., to determine the general situation of the environment where the shaft of the reducer fails. The main contents include :

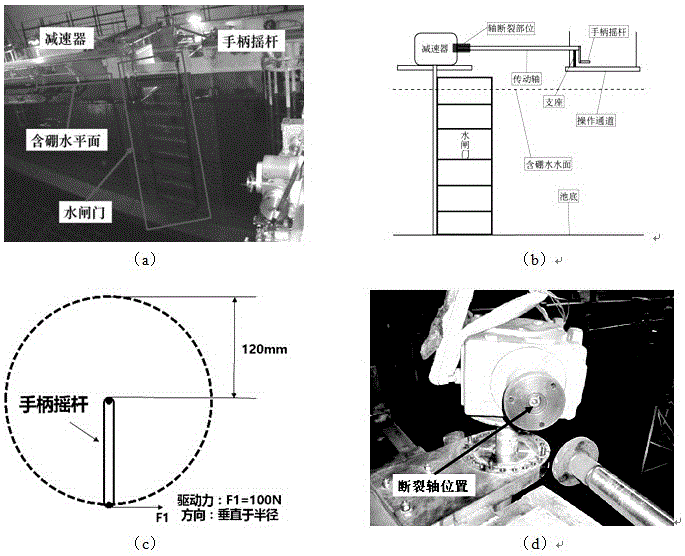

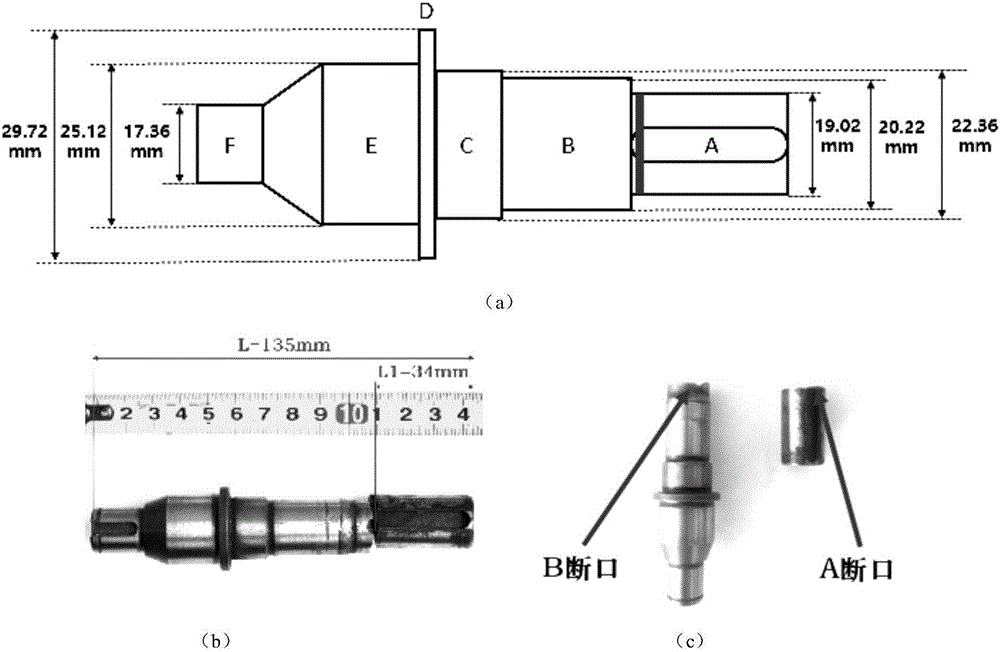

[0067] ① The background information of the nuclear power plant, including the specific functions of the plant, internal settings, functions and functions of each area, operating parameters, etc. figure 1 (a) shows the overall layout of the nuclear power plant, where the boron-containing water inside the spent fuel pool is crystal clear, and the water gate can be clearly seen. Rectangular spent fuel pool, pool surface elevation +20m, is divided into four rectangular cells. The first rectangular area next to the wall is the fuel transfer chamber,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com