Single shear test device considering tensile bar bursting force

A test device and steel bar technology, applied in the direction of measuring device, using stable shear force to test the strength of materials, instruments, etc., can solve the problems of many influencing factors, high test cost, unfavorable failure mechanism, etc., and achieve the goal of reducing the test cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

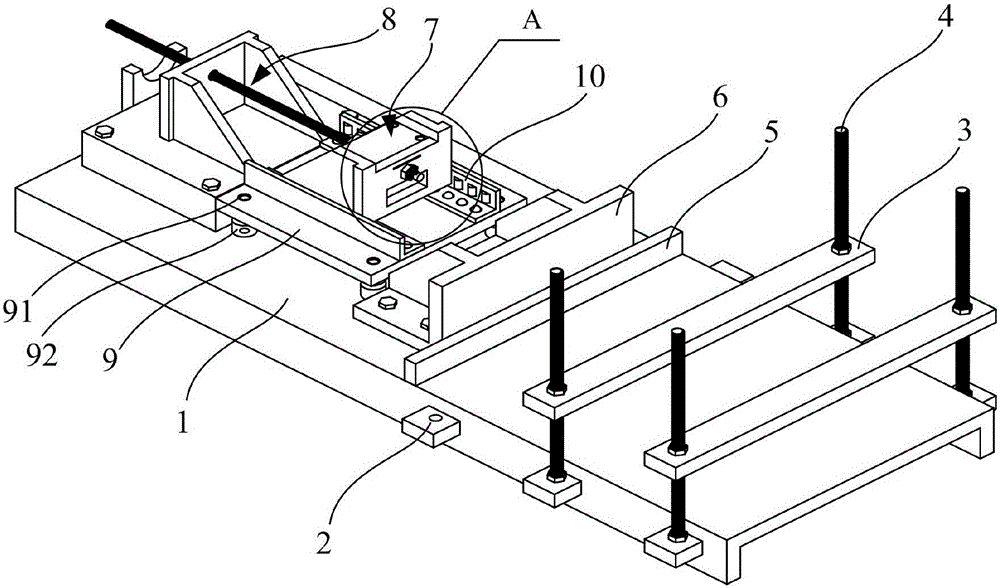

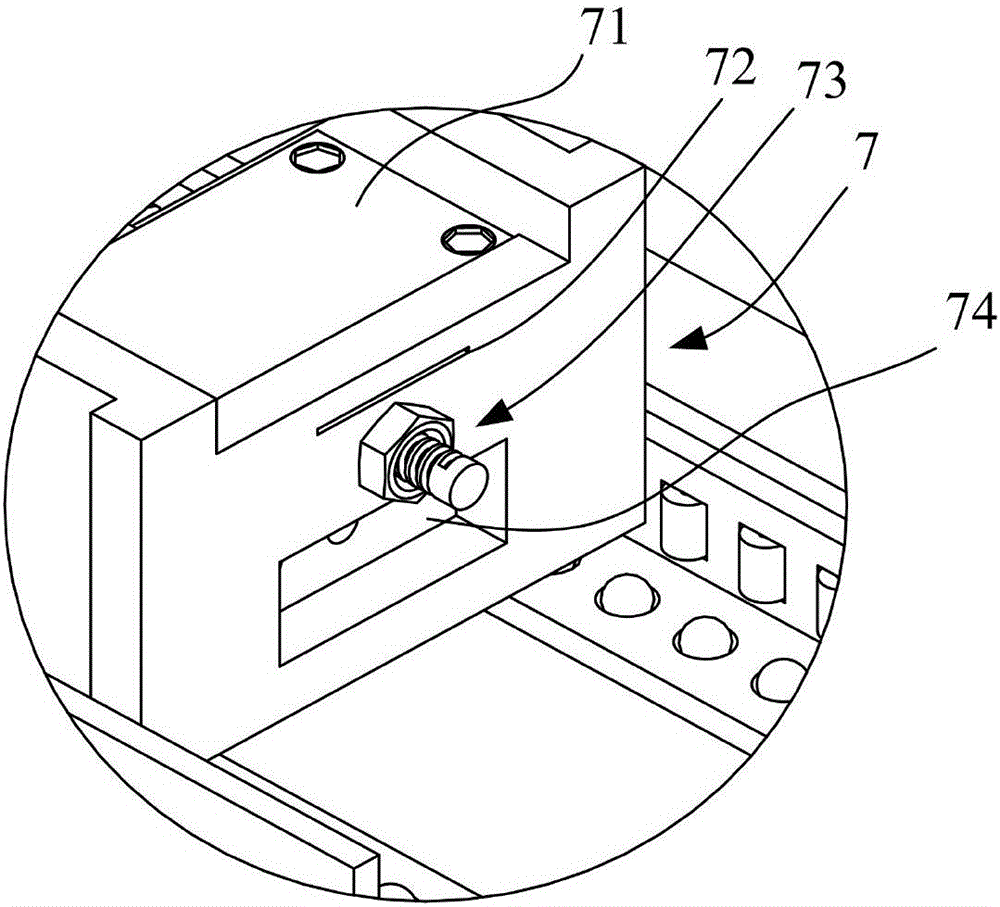

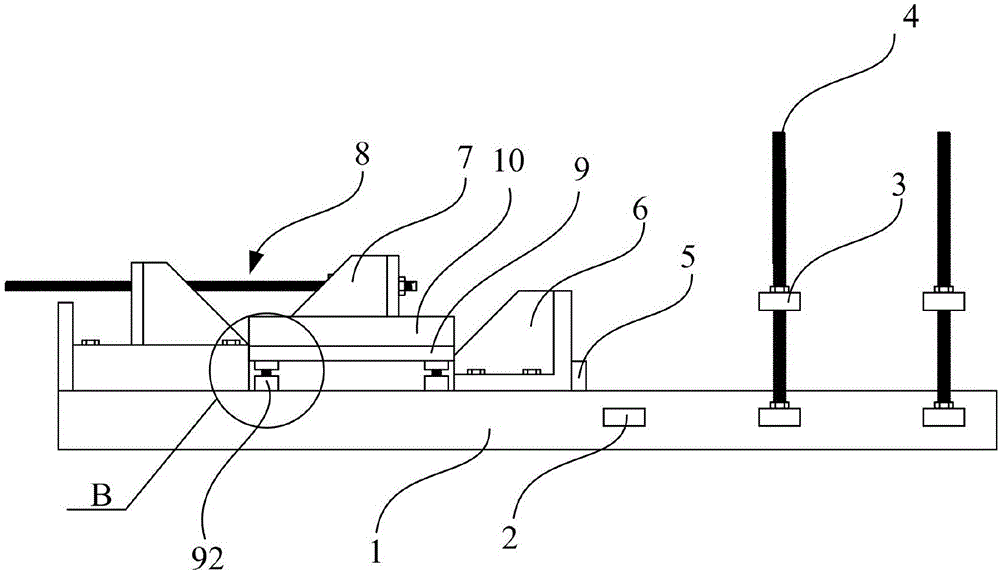

[0035] see figure 1 , the present invention proposes a single shear test device considering the splitting force of the tensioned steel bar. The top surface of the top is vertically connected with the support screw 4. A fixed plate 3 for clamping the test piece and cooperating with the support screw 4 to move up and down is provided above one end of the bottom plate 1 . In this embodiment, a number of fixing seats 2 are fixedly connected to the left and right sides of one end of the bottom plate 1, and the middle part of the fixing seats 2 is provided with a screw hole and is connected with the support screw 4 through thread fit, wherein the support screw 4 is connected to the fixing seat 2 The thread connection is detachable, so when the support screw 4 cooperates with the fixed plate 3 to clamp the test piece, the support screw 4 can be installed on different fixing seats 2, or multiple support screws 4 and multiple fixed plates 3. Cooperate with each other to clamp the tes...

Embodiment 2

[0045] This embodiment is the same as Embodiment 1 except for the following features. The sliding positioning device arranged between the fixture and the bottom plate is a linear guide rail, the fixed guide rail of the linear guide rail is fixedly connected with the top surface of the bottom plate, and the slider of the linear guide rail is fixedly connected with the bottom surface of the fixture .

[0046] Through the setting of the above structure, the fixture can slide linearly on the top surface of the bottom plate through the linear guide rail. At the same time, when the fixture slides along the linear guide rail, the linear guide rail can limit the left and right swing of the fixture, thereby improving the accuracy of sliding. It should be noted that the number of linear guide rails arranged between the fixture and the bottom plate is two, and the two linear guide rails are parallel to each other and arranged near the side of the bottom surface of the fixture, so that th...

Embodiment 3

[0048] This embodiment is the same as Embodiment 1 except the following features: a level is also provided on the leveling plate.

[0049] In this embodiment, by setting the level bar on the leveling plate, it is convenient for the experimental operator to quickly level the leveling plate in place through the movement of the water bubble of the level bar during the experimental operation. Preferably, the level provided on the leveling plate is two water bubbles parallel to the leveling plate and perpendicular to each other. The water bubbles perpendicular to each other can make the leveling of the leveling plate more convenient and fast.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com