Compact type handheld welding spot ultrasonic automatic scanner

A hand-held, compact technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, use sound waves/ultrasonic waves/infrasonic waves for material analysis, instruments, etc. , to achieve the effects of reduced size requirements, high scanning accuracy, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

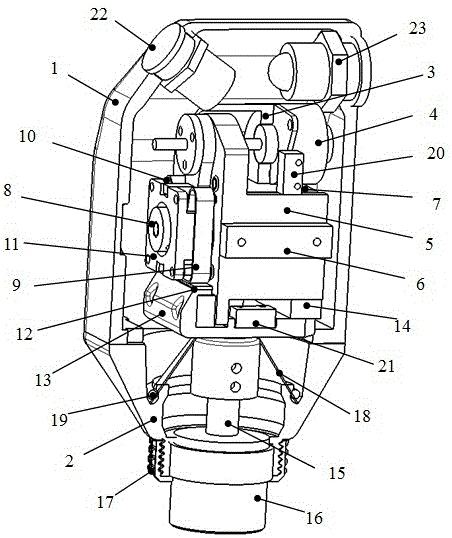

[0023] In the following, in conjunction with the accompanying drawings, the detection of a MIG solder joint workpiece with a diameter of 15 mm is taken as an example to further illustrate the details of the present invention and its specific implementation.

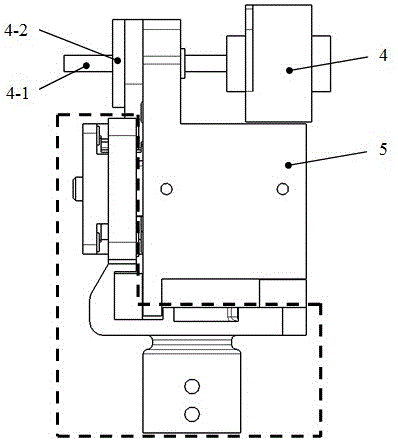

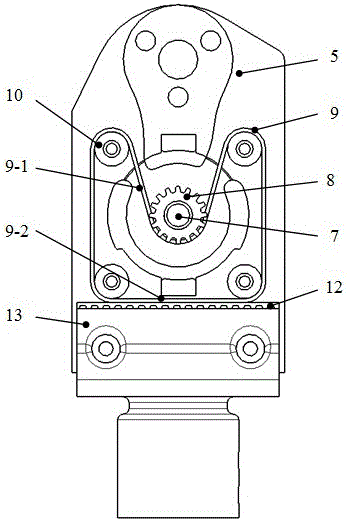

[0024] See Figure 1 to Figure 6 As shown, the compact handheld solder joint ultrasonic automatic scanner of the present invention includes a housing module, an X-direction motion module, a Y-direction motion module, an ultrasonic transmitter / receiver module, and an accessory module. The housing module is connected and fixed. The X-direction movement module and the accessory module are fixed to the housing module; the X-direction movement module has a built-in motor drive device to realize the X-direction scanning movement relative to the housing module; the Y-direction movement module is connected to the X-direction movement module , Built-in motor drive device to realize Y-direction scanning movement relative to the X-dire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap