A high light transmittance LED filament lamp and its processing technology

A technology of LED filament lamps and LED filaments, which is applied in semiconductor devices, optics, and lampshades of light-emitting elements, and can solve problems such as unfavorable heat dissipation of LEDs, affecting light output, and low light output efficiency, so as to increase internal reflection effects and improve transmittance rate, improve the effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it should not be understood that the scope of the above-mentioned theme of the present invention is limited to the above-mentioned embodiments.

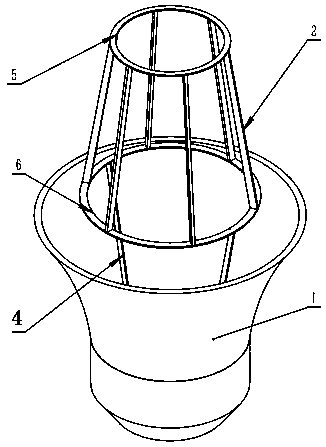

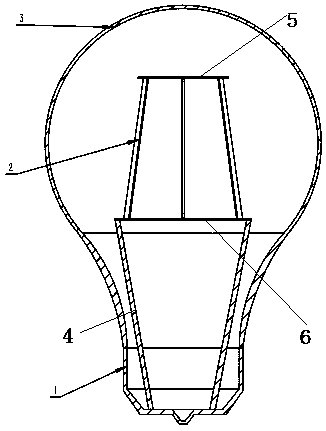

[0021] like Figure 1-2 As shown, a LED filament lamp with high light transmittance includes a lamp base 1 and a bulb 3, and the bulb 3 and the lamp base 1 form a sealed cavity; the bulb 3 is provided with an upper bracket 5 and a plurality of LED lamps from top to bottom. Filament 2, lower bracket 6 and wire 4; the upper part of the LED filament is connected to the upper bracket 5, the lower part is connected to the lower bracket 6, and the wire 4 is connected to the upper bracket 5 and the lower bracket 6 to supply power for the LED filament 2; the inside of the bulb 3 is connected to the outside There is a first layer of composite membrane and a second layer of composite membrane inside, the first layer of comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com