Novel preparation method for developing solution

A developer solution, a new technology, applied in the field of preparation of developer solution for heat-sensitive CTP plates, can solve the problems of complicated method steps and poor developing effect of the developer solution, to increase the number of hydrogen bonds, simple and effective operation steps, and ensure dissolution effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

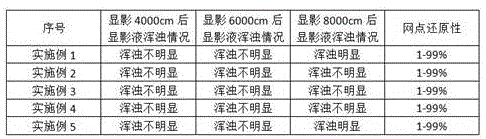

Examples

Embodiment 1

[0032] Embodiment 1: a kind of preparation method of novel developer, comprises the following steps:

[0033] (1) Stir and dissolve 9kg of salicylate in 30kg of benzyl alcohol to obtain solution a;

[0034] (2) Heat solution a to 40°C, add 59kg of isopropylamine and 31kg of triethylenetetramine as the main developing agent, stir at a stirring speed of 800r / min for 18min, and obtain solution b;

[0035] (3) Maintain the temperature of solution b at 40°C, add 12kg of wetting agent, 4kg of polyoxyethylene glyceryl ether and 0.75kg of 2-phosphonic acid butane-1,2,4-tricarboxylic acid in sequence, and stir at 200r / min Stirring at high speed for 8 minutes to obtain solution c;

[0036] (4) Add 680kg of deionized water and 7kg of citrate into solution c, stir evenly, adjust and maintain the solution temperature at 22°C, and finally obtain a developer.

[0037] During the mixing and preparation process of the developer main agent, the mixing temperature of isopropylamine and triethy...

Embodiment 2

[0041] Embodiment 2: a kind of preparation method of novel developer, comprises the following steps:

[0042] (1) Stir and dissolve 10kg of salicylate in 32kg of benzyl alcohol to obtain solution a;

[0043](2) Heat solution a to 42°C, add 62kg of isopropylamine and 32kg of triethylenetetramine as the main developing agent, stir at a stirring speed of 800r / min for 20min, and obtain solution b;

[0044] (3) Maintain the temperature of solution b at 42°C, add 14kg of wetting agent, 5kg of polyoxyethylene glyceryl ether and 1.0kg of 2-phosphonic acid butane-1,2,4-tricarboxylic acid in sequence, and stir at 200r / min Stirring at high speed for 9min to obtain solution c;

[0045] (4) Add 800kg of deionized water and 9kg of citrate into solution c, stir evenly, adjust and maintain the solution temperature at 23°C, and finally obtain a developer.

[0046] During the mixing and preparation process of the developer main agent, the mixing temperature of isopropylamine and triethylenete...

Embodiment 3

[0050] Embodiment 3: a kind of preparation method of novel developer, comprises the following steps:

[0051] (1) Stir and dissolve 11kg of salicylate in 34kg of benzyl alcohol to obtain solution a;

[0052] (2) Heat solution a to 43°C, add 68kg of isopropylamine and 30kg of triethylenetetramine as the main developing agent, stir at a stirring speed of 800r / min for 22min, and obtain solution b;

[0053] (3) Maintain the temperature of solution b at 43°C, add 17kg of wetting agent, 6kg of polyoxyethylene glyceryl ether and 1.0kg of 2-phosphonic acid butane-1,2,4-tricarboxylic acid in sequence, and stir at 200r / min Stirring at high speed for 10 min to obtain solution c;

[0054] (4) Add 850kg of deionized water and 11kg of citrate into solution c, stir evenly, adjust and maintain the solution temperature at 24°C, and finally obtain a developer solution.

[0055] During the mixing preparation process of the developer main agent, the mixing temperature of isopropylamine and trie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com