A Calculation Method of Temperature Crack Width in Track Slab

A technology of temperature cracks and calculation methods, applied in calculation, computer-aided design, design optimization/simulation, etc., can solve problems such as the inability to directly calculate the maximum crack width of track slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

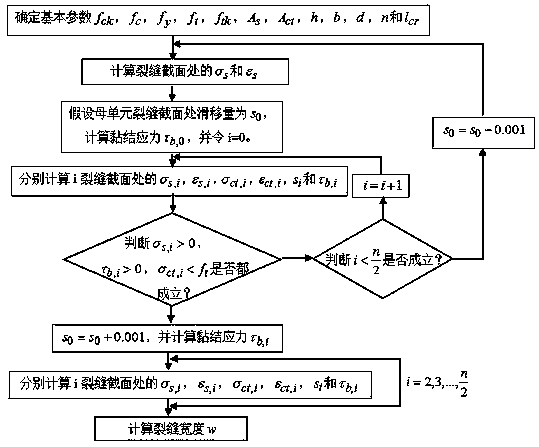

[0042] Such as figure 1 As shown, the calculation method of the track plate temperature crack of the CRTS II ballastless track in this embodiment includes the following steps.

[0043] Step 1. Determine the basic parameters of the track slab of the CRTS II ballastless track.

[0044] The track slab is poured with C55 concrete, the width b is 2.55m, and the thickness h is 0.2m; the longitudinal double layer is equipped with HRB500 fine-rolled threaded steel bars.

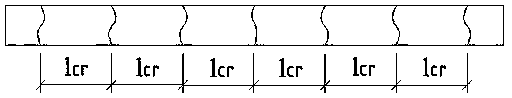

[0045] Step 2, according to figure 2 Track slab crack spacing shown , divide the track slab into several parent units, and divide each parent unit into image 3 The n shown are of length of subunits.

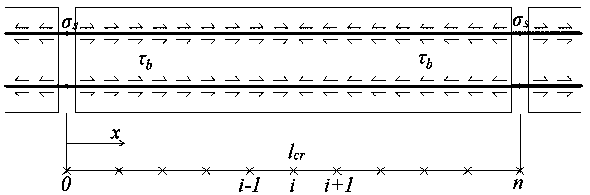

[0046] Step 3, calculate as Figure 4 Stresses in the longitudinal reinforcement at the cracked section of the parent element shown and strain .

[0047]Step 4:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com