Design method for seamless track of unitary ballastless track for long bridge of high-speed railway

A technology of slab ballastless track and seamless track, which is applied in bridge construction, bridges, bridge parts, etc., can solve the problem of less research on CRTS type slab and double-block ballastless track without seamless track, and beam-rail interaction Complicated mechanism and other issues, to achieve the effect of perfecting the technical system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

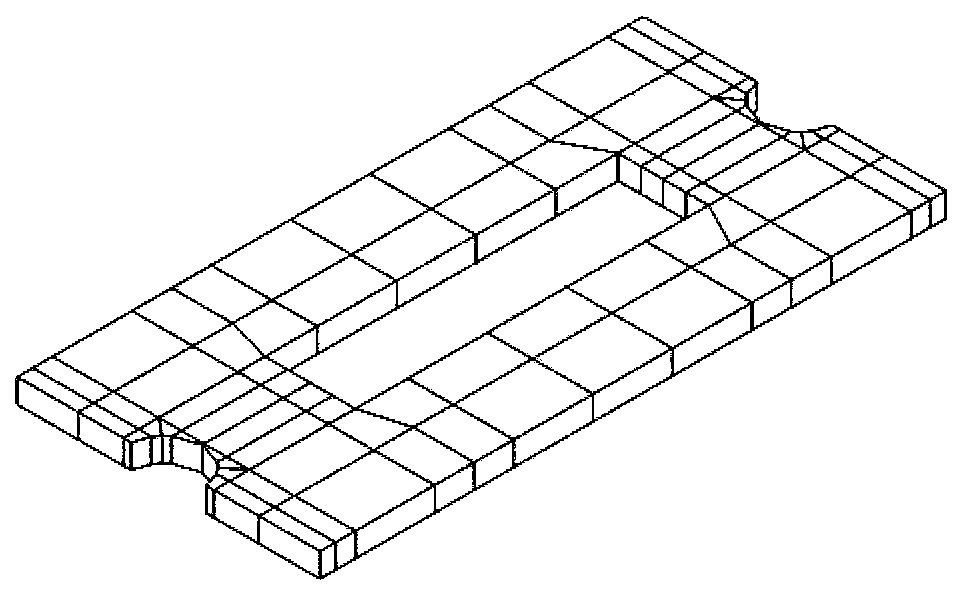

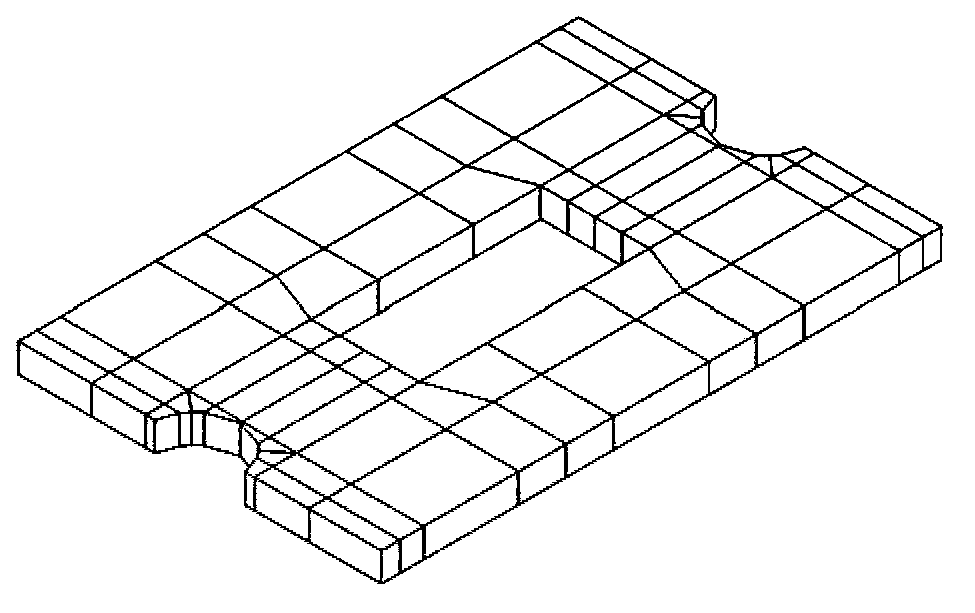

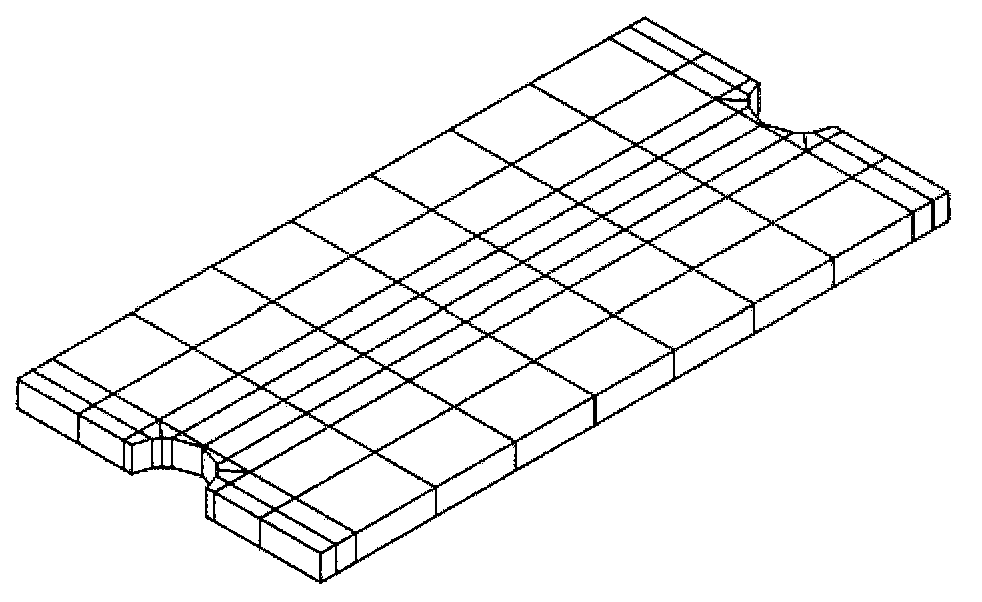

Image

Examples

Embodiment 1

[0113] In this embodiment, the statics model of vertical, horizontal and vertical spatial coupling of the CRTS I type slab ballastless track seamless track established by the present invention is used for static analysis, and the longitudinal resistance of the fasteners is compared and analyzed to be 4.0kN / group respectively. , 6.0kN / group, 8.0kN / group and 10.0kN / group calculation results of main temperature force and displacement. The comparison of rail force and rail displacement under different fastener longitudinal resistance conditions is as follows: Figure 37 and Figure 38 shown. The main temperature force and displacement calculation results under different fastener longitudinal resistance conditions are compared in Table 1 and Table 2.

[0114] Table 1: Comparison of main force calculation results under different fastener longitudinal resistance conditions

[0115]

[0116] Table 2: Comparison of main displacement calculation results under different fastener lo...

Embodiment 2

[0120] In this embodiment, the statics model of the vertical, horizontal and vertical space coupling statics model of the CRTS I type slab ballastless track seamless line established by the present invention is used for static analysis, and the longitudinal stiffness of the continuous girder pier is compared and analyzed to be 2600kN / cm respectively. , 3600kN / cm and 4600kN / cm main braking force and displacement calculation results. The comparison of rail force and rail displacement under different longitudinal stiffness conditions of continuous girder pier is as follows: Figure 39 and Figure 40 shown. Table 3 and Table 4 compare the main braking force and displacement calculation results under different longitudinal stiffness conditions of continuous girder piers.

[0121] Table 3: Comparison of main force calculation results under different longitudinal stiffness conditions of continuous girder piers

[0122]

[0123] Table 4: Comparison of main displacement calculati...

Embodiment 3

[0127] This embodiment adopts the vertical, horizontal and vertical spatial coupling dynamics model of the double-block ballastless track seamless line of the high-speed railway long bridge established by the present invention for dynamic analysis, and calculates the time-history curves of the wheel-rail vertical and lateral forces Such as Figure 41 and Figure 42 As shown, the maximum value of the wheel-rail vertical force is 129.242kN, and the maximum value of the wheel-rail lateral force is 13.344kN. The time-history curve of the lateral force of the wheel axle calculated according to the lateral force of the wheel and rail is as follows: Figure 43 As shown, the maximum value is 7.061kN. The time-history curves of the derailment coefficient and wheel load reduction rate calculated according to the wheel-rail vertical and lateral forces are as follows: Figure 44 and Figure 45 As shown, the maximum derailment coefficient is 0.152, and the maximum wheel load reduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com