Silver-containing powder, preparation method of silver-containing powder, conductive silver paste and preparation method of conductive silver paste

A technology of conductive silver paste and silver powder, which is applied in the field of preparation of silver-containing powder, preparation of conductive silver paste and conductive silver paste, and silver-containing powder. It can solve the problem of unstable silver-plated copper powder, easy oxidation of copper elements, and decreased conductivity and other problems, to achieve good electronic conduction benefits, particle size concentration, and reduce the effect of series resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

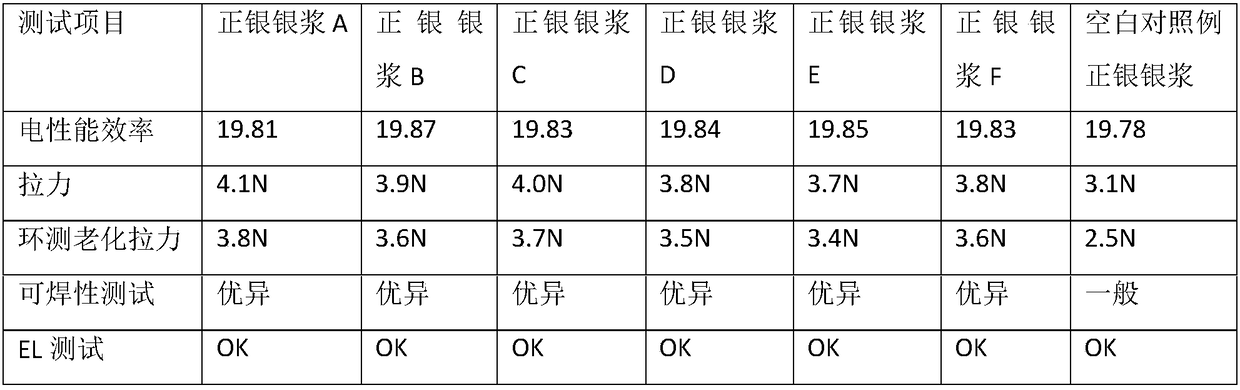

Examples

Embodiment 1

[0024] The steps of a preparation method of silver-containing powder are:

[0025] (1) First add 30 grams of polyvinylpyrrolidone and 20 grams of oleic acid in 1000 milliliters of deionized water;

[0026] (2) adding successively average particle diameter is 0.2 gram of tellurium oxide of 50 nanometers, and average particle diameter is 0.2 gram of samarium oxide of 100 nanometers, and average particle diameter is 0.2 gram of zinc oxide of 200 nanometers and silver nitrate 85 grams, is heated to 40 afterwards temperature, keep warm for 0.5 hours;

[0027] (3) adding 26.5 grams of sodium carbonate and 62.5 grams of ammoniacal liquor with a mass concentration of 28% was then incubated for 0.5 hour;

[0028] (4) After adding 92 grams of dodecanal, it was incubated for 2 hours to obtain a silver powder suspension;

[0029] (5) the obtained silver powder suspension is cleaned with de-distilled water, and the pH value of the washing solution reaches about 7;

[0030] (6) Remove pa...

Embodiment 2

[0033] The steps of a preparation method of silver-containing powder are:

[0034] (1) First add 30 grams of oleic acid and 20 grams of stearic acid in 1000 milliliters of deionized water;

[0035](2) add successively again average particle diameter is 0.2 gram of tellurium oxide of 50 nanometers, and average particle diameter is 0.2 gram of samarium oxide of 100 nanometers, and average particle diameter is 0.2 gram of bismuth oxide of 200 nanometers and silver nitrate 85 grams, is heated to after 40 degrees, keep warm for 0.5 hours;

[0036] (3) adding 26.5 grams of sodium carbonate and 62.5 grams of ammoniacal liquor with a mass concentration of 28% was then incubated for 0.5 hour;

[0037] (4) After adding 25 grams of glutaraldehyde at last, it was incubated for 2 hours to obtain a silver powder suspension;

[0038] (5) the obtained silver powder suspension is cleaned with de-distilled water, and the pH value of the washing solution reaches about 7;

[0039] (6) Remove p...

Embodiment 3

[0042] The steps of a preparation method of silver-containing powder are:

[0043] (1) First add 30 grams of polyvinylpyrrolidone and 20 grams of polyurethane in 1000 milliliters of deionized water;

[0044] (2) adding successively an average particle diameter is 0.01 gram of tellurium oxide of 50 nanometers, an average particle diameter is 0.01 gram of lanthanum oxide of 100 nanometers, an average particle diameter is 0.01 gram of bismuth oxide of 200 nanometers and 85 grams of silver nitrate, and is heated to 40 degrees, keep warm for 0.5 hours;

[0045] (3) then adding mass concentration is 70 grams of ammoniacal liquor of 28%, insulation 0.5 hour;

[0046] (4) After adding 128 grams of ascorbic acid at last, it was incubated for 2 hours to obtain a silver powder suspension;

[0047] (5) the obtained silver powder suspension is cleaned with de-distilled water, and the pH value of the washing solution reaches about 7;

[0048] (6) Remove part of the moisture from the silv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com