Controllable equilibrium flow film resistance-reducing negative-pressure defoaming device

A technology of flow film and resistance reduction, which is applied in the direction of electrical components, circuits, conductor/cable insulation, etc. It can solve the problems of reducing the quality of polyimide film, not easy to remove air bubbles, and high density of gelatinous substances, so as to increase the floating and blasting power, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

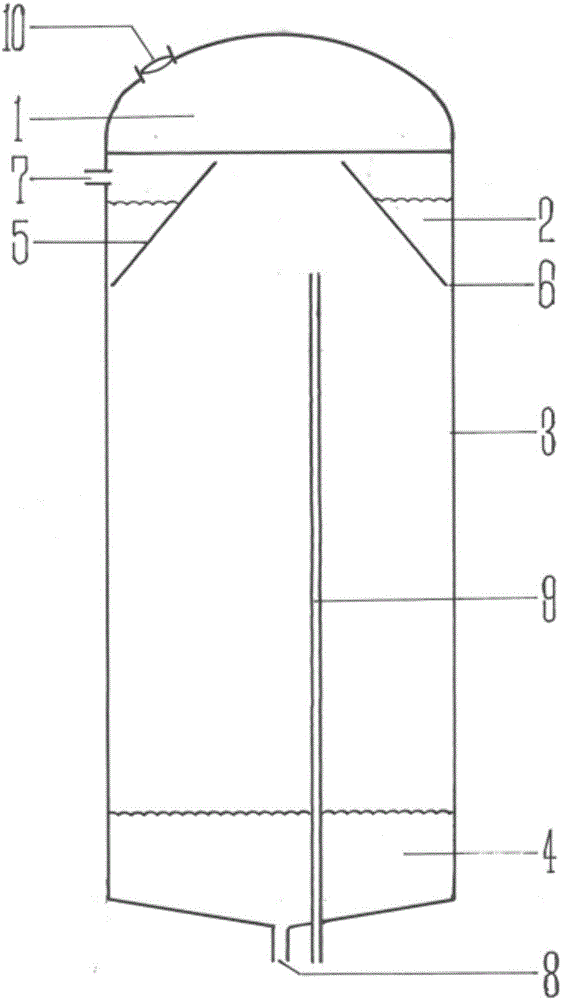

[0018] A controllable and balanced flow film resistance-reducing negative pressure defoaming device of the present invention will be further described in detail in conjunction with the accompanying drawings below:

[0019] Such as figure 1 Shown, the present invention comprises sealing cover 1, raw material trough 2, flow film wall 3, finished product trough 4, umbrella-shaped trough 5, annular leakage wall 6, feed opening 7, discharge opening 8, suction pipe 9 and peep The window 10 is characterized in that the angle between the concentrically designed and installed cylindrical kettle body and the umbrella-shaped tank wall forms a raw material tank 2, and the diameter of the lower edge of the umbrella-shaped tank wall is 2-4mm smaller than the diameter of the kettle body. The gap forms an annular drain wall 6, and the wall of the kettle body below the annular drain wall 6 is a flow film wall 3, which is frosted. The upper side of the raw material tank 2 is provided with a fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com