Parallel dual-driving connected permanent magnet motor twin-screw pump system

A permanent magnet motor and twin-screw pump technology, applied in the direction of rotary piston/oscillating piston pump combination, pump, magnetic circuit, etc., can solve the problem of strict sealing and leakage requirements, lubricating oil leakage pollution, and gear maintenance costs High-level problems, to achieve the effect of flexible speed, energy saving and consumption reduction, and excellent sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

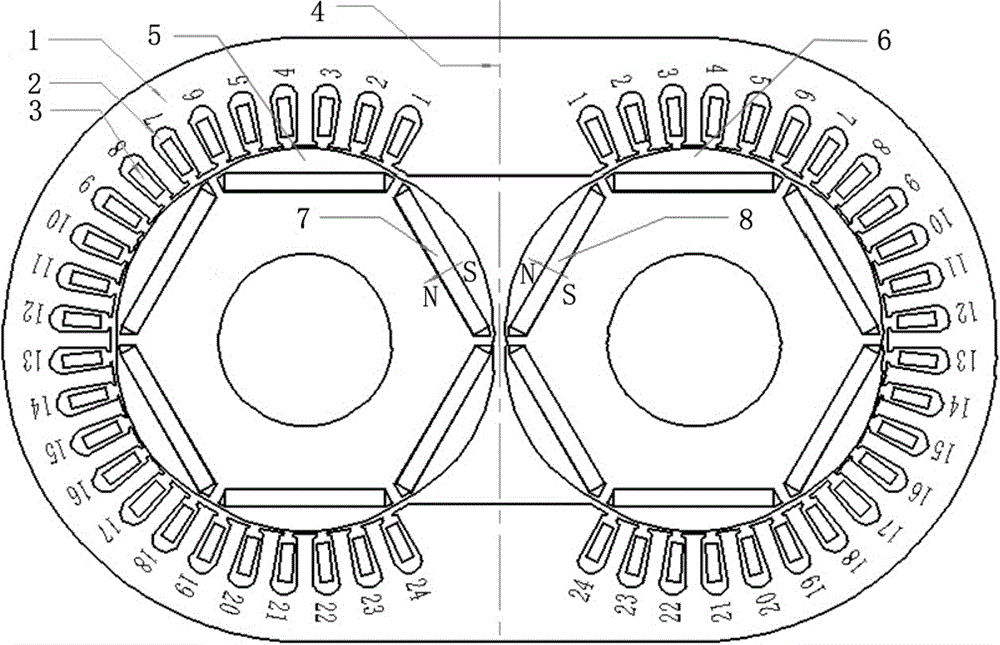

[0021] Such as figure 1 As shown, taking a 36-slot motor as an example, after the two cylindrical stators each cut off the 360° electrical angle stator core, the remaining part forms two identical 24-slot structure stators, and the two stators are placed side by side and connected together, up and down The same material is filled and welded flat to form a one-piece stator with mirror symmetry on the vertical symmetry line 4. The two internal cavities of the stator core 1 form an approximate "∞" structure, the two ends of the outer contour of the cross section are arc-shaped, and the upper and lower ends are planar. The stator slots 2 on the left and right sides are evenly distributed on the inner wall of the one-piece stator core 1 cavity, and the three-phase symmetrical winding 3 is embedded in the stator slot 2, and the three-phase symmetrical current is passed through, and the slots 1 to 24 on the left and right sides are the same The serial number slots have the same curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com