Fully-automatic marker

A fully automatic, rack-mounted technology, applied in printing devices, printing, etc., can solve problems affecting production efficiency, slow marking methods, etc., and achieve the effects of fast processing speed, low cost, and high level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

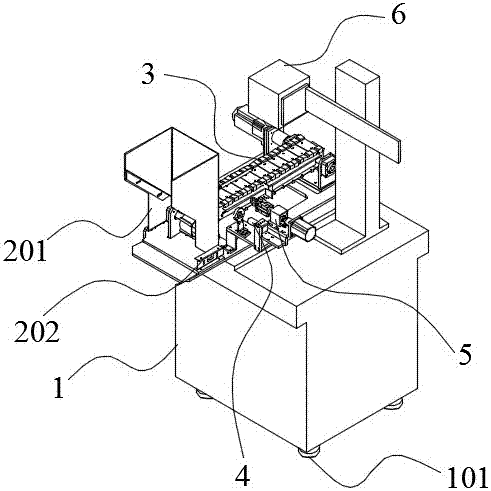

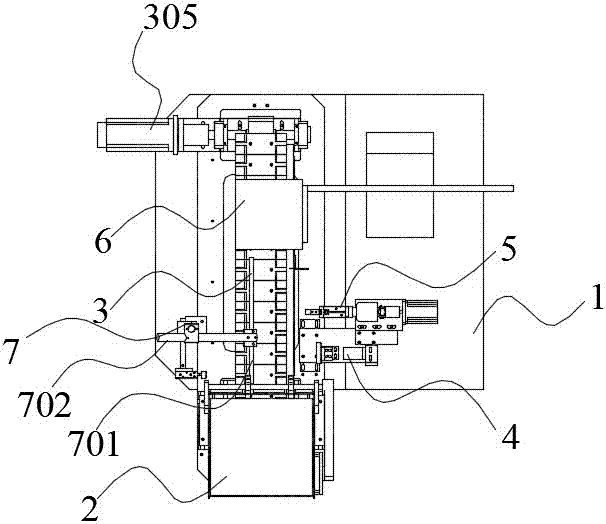

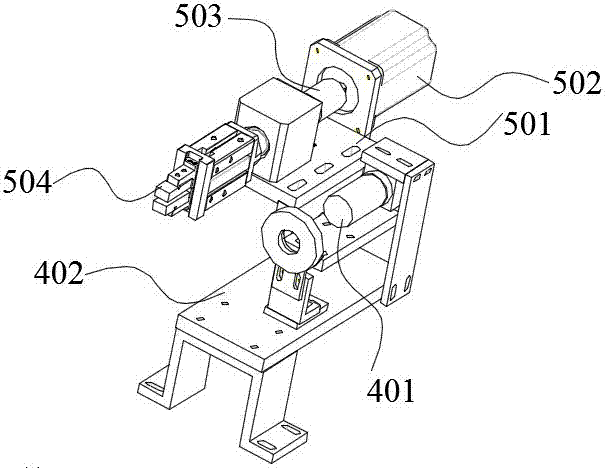

[0024] In this embodiment, a kind of automatic marking machine that the present invention proposes, such as figure 1 , figure 2 , image 3 As shown, it includes: frame 1, unloading device 2, conveying device 3, image recognition device 4, turning device 5, marking device 6, frame 1 is a hollow cubic workbench composed of profiles, and unloading device 2 is set On one side of the upper surface of the frame 1, including a hopper 201 and a fixed block 202 for fixing the hopper 201, the front bottom of the hopper 201 is provided with a discharge port, and the discharge port is connected with the initial end of the conveying device 3, and the conveying device 3 Placed flat on the frame 1 , the image recognition device 4 , the flipping device 5 , and the marking device 6 are sequentially arranged on the same side of the conveying device 3 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com