Method for controlling metro stray current corrosion of reinforced concrete

A technology of reinforced concrete and stray current, which is applied in the field of subway infrastructure, can solve the problems that corrosion is not necessarily effective, and achieve the effect of reducing driving force and changing electromotive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

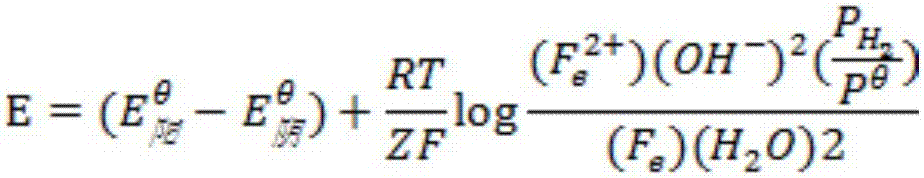

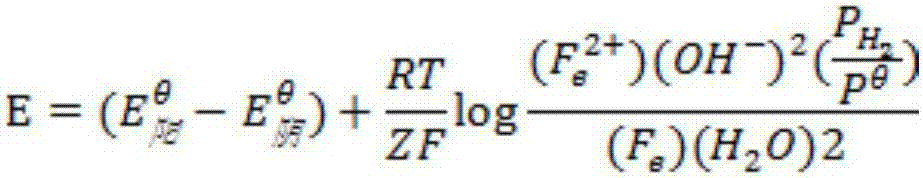

Method used

Image

Examples

Embodiment 1

[0028] A method for controlling the corrosion of reinforced concrete by subway stray currents, calcining layered double hydroxide (hydrotalcite) at 500°C for 6 hours, and then dissolving the calcined hydrotalcite in a 20% sodium hydroxide solution Soak in water for 12h, filter with water, and dry. The dried hydrotalcite is mixed into the concrete cementitious material at a mass ratio of 5%, mixed and stirred in a mixer, and shaped reinforced concrete is poured.

Embodiment 2

[0030] A method for controlling the corrosion of reinforced concrete by subway stray current, calcining the layered double hydroxide (hydrotalcite) in the range of 550°C for 7 hours, and then dissolving the calcined hydrotalcite in a 30% sodium hydroxide solution by mass ratio Soak in water for 18 hours, filter with water, and dry. The dried hydrotalcite is mixed into the concrete cementitious material according to the mass ratio of 8%, mixed and stirred in the mixer, and the shaped reinforced concrete is poured.

Embodiment 3

[0032] A method for controlling stray current corrosion of steel reinforced concrete in subways, calcining layered double hydroxide (hydrotalcite) in the range of 580°C for 7.5h, and then dissolving the calcined hydrotalcite in 35% sodium hydroxide Soak in the solution for 20h, filter with water, and dry. The dried hydrotalcite is 9% by mass, mixed into the concrete cementitious material, mixed and stirred in a mixer, and shaped reinforced concrete is poured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com