Vehicle model die assembly for comprehensive pipe gallery construction

A technology of integrated pipe gallery and components, applied in construction, water conservancy projects, artificial islands, etc., can solve problems such as difficult quality control, inconvenient demoulding, and high engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

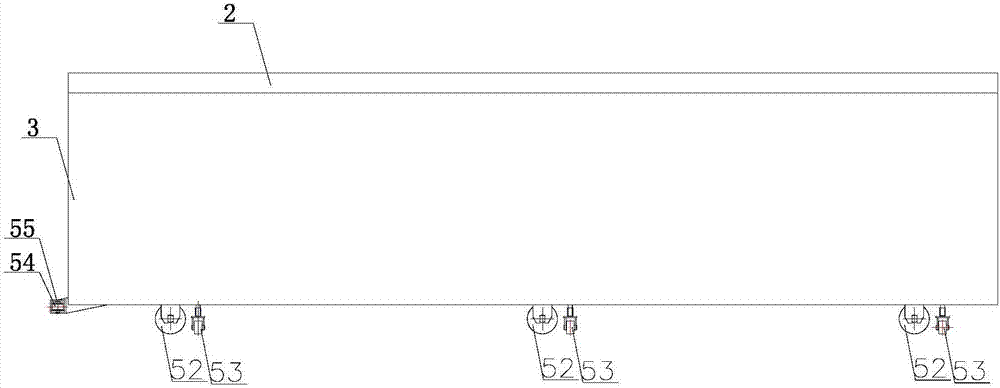

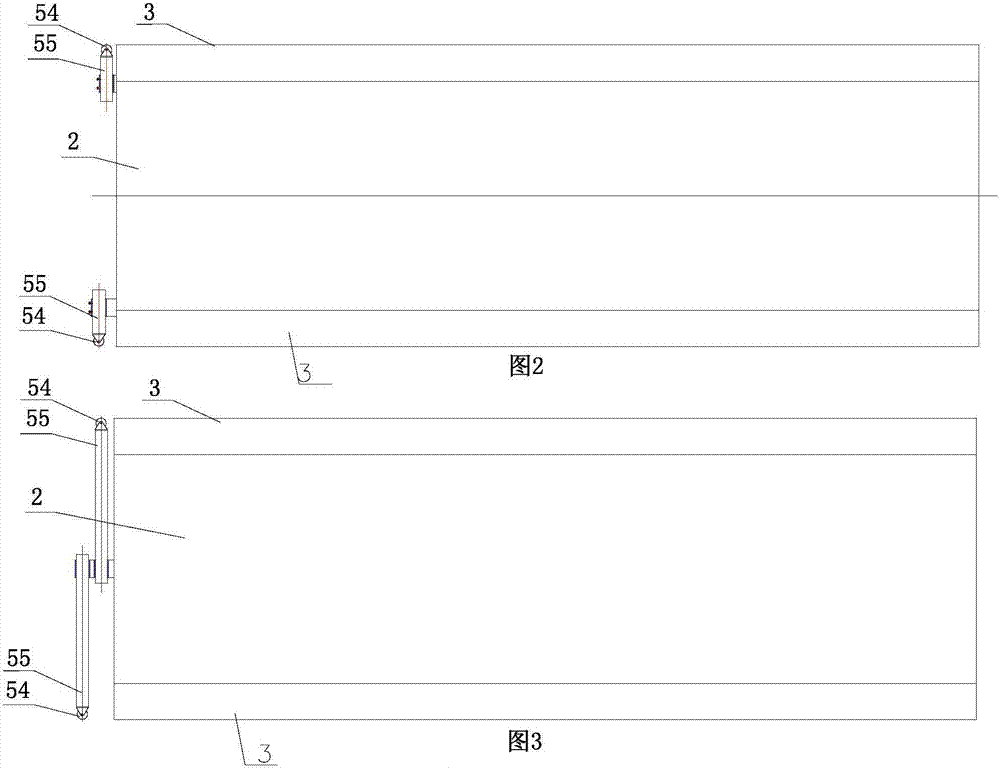

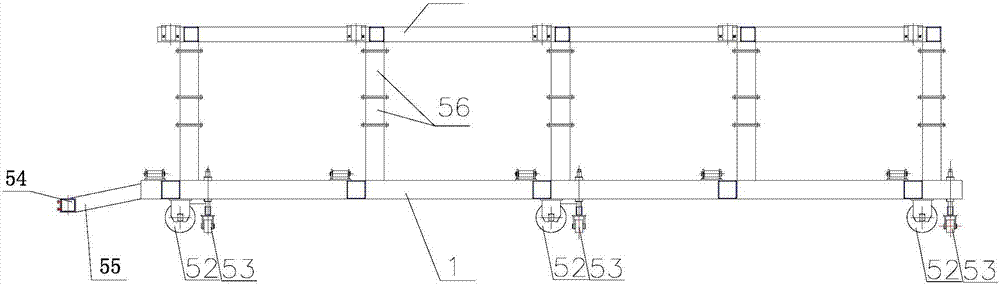

[0061] The following with attached Figure 1 to Figure 22 A vehicle mold assembly for construction of a comprehensive utility gallery according to the present invention will be further described in detail.

[0062] A vehicle model mold assembly for the construction of a comprehensive pipe gallery according to the present invention, please refer to Figure 1 to Figure 22Relevant figures include a vehicle frame body 1, a top mold assembly 2 and two side mold assemblies 3, and the top mold assembly 2 passes through at least two lifting devices arranged at intervals along the length direction of the side mold assembly 3 5. It can be lifted and flexibly connected to the top of the frame body 1. The two side mold assemblies 3 are respectively located on the left and right sides of the frame body 1. The two side mold assemblies 3 are respectively passed along the side At least two telescopic devices 6 arranged at intervals in the length direction of the mold assembly 3 are telescopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com